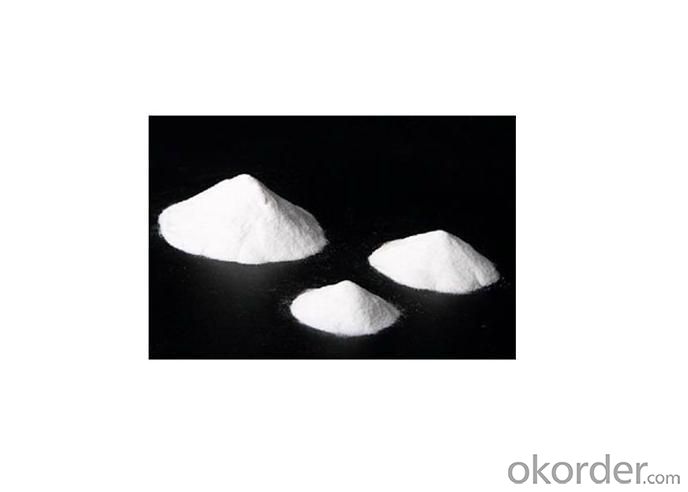

TPU Hot Melt Adhesive Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 10000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

TPU hotmelt adhesive powder:

waterproof

good impact resistance

good rebound elasticity

excellent flexibility

The characteristic and application of PU powder

PU shows high hardness,high flexibility,lamination with low temperature,high crystallization rate.

PU can be applied to all kind of material for the shoes and for the textile lamination such as pvc film,pu film,pet,nylon,waterproof zipper and so on.Also can be applied on furniture,automobile industry and industrial application.

TDS

|

Reference Product properties |

HT-9150 | |

|

Appearance Form |

Powder | |

|

Components |

PU(polyurethane) | |

|

Melting range DSC (°C) |

75-85 | |

|

Melt-index (g/10min) (160°C/21.18N) |

10-20 | |

|

Density (g/cm3) |

1.21 | |

|

Particle sizes/Method of application |

0-80µm |

Paste dot |

|

80-200µm |

Scatter for double dot | |

|

200-400µm |

Powder scattering | |

|

Bonding condition (for reference only) |

Temperature (°C) |

90-120 |

|

Press (kg/cm2) |

1.5-2.0 | |

|

Time (S) |

5-10 | |

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the barrel is "4", the main component of this kind of plastic barrel is low-density polyethylene, also called LDPE. Such plastic barrels of heat resistance is not strong, in case of high temperature, there will be hot melt phenomenon, will produce some of the body can not be decomposed plastic preparations, may cause breast cancer, neonatal congenital defects and other diseases.

- Q: What material is the disc made of, metal or plastic?

- The compact disk is the carrier of functional structures (such as grooves, etc.), and its material is polycarbonate (PC), which has excellent impact toughness, large temperature range, good dimensional stability, weatherability and non toxicity.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA6 also known as nylon 6 is translucent or opaque white particles, thermoplastic, light weight, good toughness, chemical resistance and good durability and other characteristics, generally used for auto parts, machinery parts, electronic products, engineering accessories and other products.

- Q: What is the ash content of PP plastic raw materials?

- If the PP plastics added talc, glass fiber, mineral fiber and other inorganic additives, there will be ash, the specific ingredients and quantity depends on what is added to it

- Q: What type of raw material for plastic straw?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization (macromolecules), commonly known as plastic resin (plastics) or (resin), can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q: What raw materials do plastic color printing plants use?

- Mainly plastic film and ink, the film is generally in accordance with the nature and requirements of products such as PVC film, POF film

- Q: What kind of plastic material is used for medical instruments?

- You need to add various additives in plastics processing or modification process, such as in the PVC medical products in the amount of the plasticizer is as high as 30 - 60%, so as far as possible the use of non-toxic additives, long-term use to prevent or reduce the additive precipitation, so as not to affect the product performance and the therapeutic effect;

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- In comparison, the lower melt flow rate is applicable to the extrusion grade, and the higher is applicable to the injection molding grade. As to what is low and what is high, there is a difference between the different plastic varieties.

- Q: What does MFI mean in PC material?

- MFI- melt flow index, also known as the melt flow rate (MFR), it was determined at a given shear stress (with applied load) and temperature, melt flow properties of materials (measured by g/10min).

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | 70.00% Domestic Market 7.00% Southeast Asia 7.00% Western Europe 3.00% Southern Europe 3.00% South Asia 2.00% Northern Europe 1.00% North America 1.00% South America 1.00% Eastern Europe 1.00% Africa 1.00% Oceania 1.00% Mid East 1.00% Eastern Asia 1.00% Central America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo,Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

TPU Hot Melt Adhesive Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 10000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches