Welded Wire Mesh Fence 1/2 Inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Sets set

- Supply Capability:

- 10000 Square Meters per Week set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

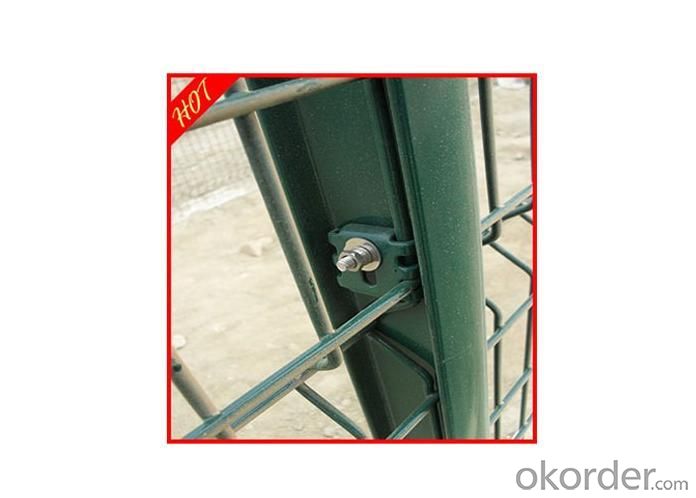

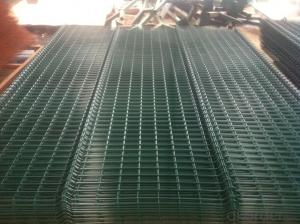

1/2-inch welded wire mesh fence

anti-corrosion waterproof

50mmx100,50x200,75x150 etc.

ISO9001/2000

wire mesh fence

1.wire mesh fence detailed descripition

wire mesh fence is also known as welded wire mesh fence,welded fences or welded fencing.This fence is pretty light yet durable,its composition is simply wire welded together to make a fece.The welds are fairly strong.

2.Material:

Low carbon steel wire,galvanized wire,aluminum alloy wire,stainless steel wire

3.Fence is a freestanding structure designed to restrict or prevent movement across a boundary.

Fence are constructed for several purposes.including:

1.) Agricultural fencing: to keep livestock in or predators act.

2.) Temporary fencing: to provide safety and security and to direct movement.wherever temporary access control is required,especially on building and construction sites.

3.)Boundary fencing: to demarcate a piece of real property.

4.) Barbed wire fence: can be made in different styles as per requirement,like for agricultural pruposes.protecting livestock,demaring property, etc

5.) Chain link fencing: is most commonly available galvanized which is silver color. We also carry colored chain link fence.

- Q: What material is best for plastic gears?

- At present, the demand for plastic gear with high wear resistance and noiseless gear is very strong. POLYMSJ noiseless nylon composite occupies a leading position in this field. If it doesn't solve the problem, you can try it out.

- Q: What are the plastic bags made of?

- Barrels are usually produced in HDPE, and as for plastic bags, these materials can be made, including polypropylene. Relatively soft is made of high pressure material, relatively hard bag is made of low pressure material, hard and quite, is PP do. Linear low density polyethylene has a strong tear resistance and is generally improved by adding a certain percentage to high pressure polyethylene. The requirements are not too high to add some recycled materials and should be appropriate to reduce the cost of filling masterbatch.

- Q: Can PE material be used as food grade plastic?

- Yes, but the raw material suppliers have already divided the ingredients into food grade, and they will be used in non food occasions to contain substances harmful to the body

- Q: What is plastic material E-PET?

- With the prevalence of the hardware industry, more industry technology is dazzling, and the technology that we know may not be even longer, so here we are talking about what is the real PET plastic.Polybutylene terephthalate mainly consists of polyethylene terephthalate two (PET) and polybutylene terephthalate (two) (PBT).PET is highly symmetrical and has certain crystalline orientation ability, so it has high film forming ability and plasticity. PET has good optical properties and weather resistance, and amorphous PET has good optical transparency. In addition, PET has excellent wear resistance, friction and dimensional stability, and electrical insulation. PET bottles are widely used because of their high strength, good transparency, non-toxic, impermeable, light quality and high production efficiency. PBT and PET molecular chain structure similar, most of the same nature, but the main chain from two methylene into four, so the molecules are more supple, processing performance is better.

- Q: What are the raw materials of plastics made of?

- Synthetic resin refers to coal, petroleum, natural gas, calcium carbide and some agricultural products as the main raw material, the low molecular weight compounds prepared firstly has certain synthetic conditions (monomer), and then through chemical and physical methods for the synthesis of high molecular compound. The characteristics of this kind of compounds similar to natural resin (such as rosin, shellac, amber, etc.), but the performance and more superior than the natural resin.

- Q: What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- Raw material is crude oil refining, renewable materials are garbage recycling, and some will have additives in the regeneration. If it is not cleaned, there may be impurities.

- Q: What raw materials do plastic color printing plants use?

- Mainly plastic film and ink, the film is generally in accordance with the nature and requirements of products such as PVC film, POF film

- Q: What kind of raw material is plastic hollow board made of?

- Plastic hollow board is non-toxic, tasteless, moisture proof, corrosion resistance, light weight, beautiful appearance, rich color, pure, and has anti bending, anti ageing, anti tensile, compression and tear strength of higher performance, according to user needs, the production of plastic hollow plate thickness is 2-7mm, the width is less than or equal to 2.3m, no length limit. Ordinary hollow plate, hollow plate, anti-static and flame retardant conductive hollow plate hollow plate.

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water.

- Q: What are the raw materials made of modified plastics?

- Broadly speaking, the modification is to change the original performance, such as TPU, flame retardant, anti UV and so on; a narrow sense, the industry will be the new material of TPU polymerization, production is not called modified, and those who buy TPU new material made of flame retardant TPU, called "back modified". The modification process involves adding some resins or additives.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | HACCP ;ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjin,huanghua,ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, French |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Welded Wire Mesh Fence 1/2 Inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Sets set

- Supply Capability:

- 10000 Square Meters per Week set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords