Welded Wire Mesh for Chicken Fence-1 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

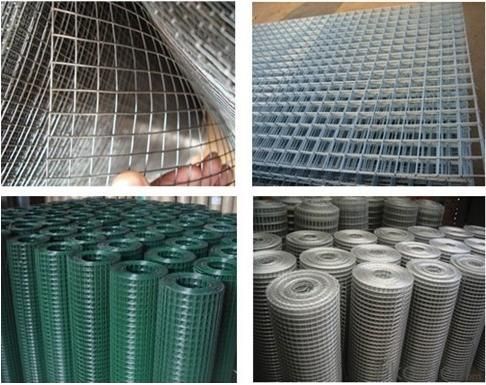

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to impact?

- In general, steel wire mesh is resistant to impact. Its strong and rigid composition enables it to endure high levels of impact without experiencing any damage or deformation. Its durability and capacity to absorb and distribute impact forces make it appropriate for numerous applications that necessitate impact resistance. Nonetheless, the actual resistance to impact may differ depending on the thickness and quality of the steel wire mesh. It is recommended to consult the manufacturer or supplier to guarantee that the steel wire mesh complies with the necessary impact resistance standards for its intended use.

- Q: How is steel wire mesh used in the agriculture industry?

- The agriculture industry extensively employs steel wire mesh for various purposes. Fencing and enclosures are one of its primary applications. Steel wire mesh is frequently used to establish boundaries, safeguard crops and livestock, and prevent unwanted animals from trespassing into agricultural areas. Its robust and long-lasting nature ensures its resilience against the elements, providing reliable security. In addition, steel wire mesh finds significant use in plant support within agriculture. Gardeners and farmers often rely on wire mesh to construct trellises, cages, and supports for climbing plants like tomatoes, beans, and cucumbers. This aids in maintaining the plants' structure, preventing them from toppling over, and facilitating better air circulation and sunlight exposure. Consequently, this results in healthier crops with higher yields. Steel wire mesh is also commonly employed in constructing animal enclosures and cages. It finds frequent utilization in poultry and livestock farming, enabling the creation of secure and safe enclosures for animals. This prevents them from wandering off or becoming prey to predators. By adjusting the mesh spacing according to the animals' size and type, their well-being and safety are ensured. Furthermore, steel wire mesh plays a vital role in the manufacture of beekeeping equipment. It is used to construct bee hives and frames, providing a sturdy structure for the bees to construct their combs and store honey. The mesh's small openings allow for proper ventilation while effectively preventing the bees from escaping. To summarize, steel wire mesh is an indispensable component within the agriculture industry. Its versatility, strength, and durability make it the ideal material for fencing, plant support, animal enclosures, and beekeeping equipment. By providing essential security and support, it significantly contributes to the overall success and productivity of agricultural operations.

- Q: What are the installation requirements for steel wire mesh?

- The installation requirements for steel wire mesh typically include the following steps: 1. Planning: Before installing the steel wire mesh, it is essential to carefully plan the layout and design of the installation. This involves determining the dimensions, shape, and location of the mesh panels, as well as considering any specific requirements or regulations for the project. 2. Surface preparation: The surface onto which the steel wire mesh will be installed should be properly prepared. This generally involves cleaning the area to remove any debris, dirt, or loose materials. If necessary, the surface may also need to be leveled or smoothed out to ensure a flat and even base for the mesh. 3. Anchoring: Depending on the application and specific requirements, steel wire mesh may need to be anchored or secured in place. This can be done using various methods such as using clips, fasteners, or ties. The anchoring technique will depend on factors such as the type of mesh, the substrate material, and the intended use of the installation. 4. Cutting and shaping: In some cases, the steel wire mesh may need to be cut or shaped to fit specific areas or conform to certain designs. This can be achieved using appropriate tools such as wire cutters or shears. It is important to ensure precise measurements and accurate cuts to achieve a seamless and secure installation. 5. Installation: Once the surface is prepared and the mesh is cut and shaped if necessary, it can be installed. The mesh should be carefully positioned and secured according to the planned layout. This may involve overlapping panels, connecting them using appropriate fasteners, or attaching them to a supporting structure. 6. Inspection and finishing: After the installation is complete, it is crucial to inspect the steel wire mesh for any defects, damage, or misalignment. Any issues should be addressed and corrected promptly to ensure the effectiveness and longevity of the installation. Depending on the application, additional finishing touches such as coatings or treatments may be necessary to enhance the durability or aesthetics of the mesh. Overall, proper installation of steel wire mesh requires careful planning, surface preparation, anchoring, cutting and shaping, precise installation, and thorough inspection. Adhering to these requirements will help ensure a successful and long-lasting installation of steel wire mesh.

- Q: Is steel wire mesh suitable for use in agricultural applications?

- Yes, steel wire mesh is suitable for use in agricultural applications. Steel wire mesh is durable, strong, and resistant to harsh weather conditions, making it ideal for various agricultural purposes. It can be used as fencing to protect crops from animals and to create enclosures for livestock. Steel wire mesh can also be used as trellises or support structures for climbing plants such as beans or grapes, providing them with stability and promoting efficient growth. Additionally, it can be used as a barrier to prevent pests from entering certain areas or to create partitions within a greenhouse. Overall, steel wire mesh is a versatile and reliable material for agricultural applications.

- Q: To the construction of steel wire mesh in the construction of what role can cancel?

- 4. to prevent the ground crack: steel wire must be placed on the pipe above the concrete is better (the ground cracked tile rupture of the reasons is not a steel mesh, the second is the ground concrete pouring too thin, concrete pouring to 4-5cm above)

- Q: How is steel wire mesh used in reinforcement of stadiums?

- Steel wire mesh is commonly used in the reinforcement of stadiums primarily for its strength and durability. The mesh is made up of interconnected steel wires, forming a grid-like pattern that provides structural support and reinforcement to concrete structures. In the construction of stadiums, steel wire mesh is typically placed within the concrete to enhance its tensile strength. Concrete itself is strong in compression but weak in tension, so the addition of steel wire mesh helps to counteract this weakness. The mesh is usually positioned in areas that are prone to stress or potential cracking, such as the walls, floors, and columns of stadium structures. It helps to distribute the forces and loads evenly across the concrete, preventing the formation of cracks and ensuring the overall structural integrity of the stadium. Furthermore, steel wire mesh also provides additional benefits such as preventing the formation of shrinkage cracks caused by temperature changes or settling of the ground. It acts as a reinforcement barrier that holds the concrete together, reducing the likelihood of structural damage and increasing the lifespan of the stadium. Another advantage of using steel wire mesh in stadium reinforcement is its ability to resist impact forces. This is particularly important in stadiums where large crowds gather and there is a higher risk of accidents or unexpected loads. The mesh acts as a safety measure, absorbing and distributing the impact forces, minimizing the potential for structural failure. Additionally, steel wire mesh is relatively lightweight, making it easier to handle and install during the construction process. It can be easily cut and shaped to fit the specific requirements of the stadium design, offering flexibility in its application. In conclusion, steel wire mesh is an essential component in the reinforcement of stadiums due to its strength, durability, and ability to distribute forces evenly. By enhancing the tensile strength of concrete, it plays a crucial role in ensuring the structural integrity and safety of stadiums, while also extending their lifespan.

- Q: What are the common uses of steel wire mesh in construction?

- Steel wire mesh is commonly used in construction for a variety of purposes. One of the main uses of steel wire mesh is in concrete reinforcement. The mesh is placed within the concrete to provide additional strength and support, preventing cracks and improving the overall durability of the structure. This is particularly important in areas where the concrete will be subjected to heavy loads or potential impacts. Another common use of steel wire mesh in construction is in the creation of barriers and fences. The mesh can be used to create secure enclosures, such as animal pens or safety barriers around construction sites. It provides a strong and secure boundary, while still allowing visibility and airflow. Steel wire mesh is also used in construction for its ability to provide a level of protection and safety. It can be used to cover openings or gaps in structures, preventing the entry of debris, animals, or unauthorized individuals. Additionally, steel wire mesh can be used as a safety measure on windows or balconies, preventing falls and ensuring the well-being of occupants. In some cases, steel wire mesh is used for decorative purposes in construction. It can be used as a design element in walls, ceilings, and facades, adding texture and visual interest to the structure. The mesh can also be used as a support for climbing plants, creating a green and natural aesthetic. Overall, steel wire mesh is a versatile material that finds numerous applications in construction. Its strength, durability, and flexibility make it an ideal choice for reinforcing concrete, creating barriers, providing safety, and adding decorative elements to buildings and structures.

- Q: Can steel wire mesh be used for sunshade?

- Sunshade can indeed be achieved with the use of steel wire mesh. This versatile material offers a multitude of advantages when it comes to sunshade applications. Its exceptional durability and strength enable it to withstand unfavorable weather conditions and prolonged exposure to sunlight. Moreover, steel wire mesh facilitates proper ventilation, allowing air to freely circulate while effectively blocking harmful UV rays. This makes it an optimal choice for constructing shade structures in outdoor spaces, including patios, gardens, or parking lots. Additionally, the flexibility in design and installation allows for easy customization of steel wire mesh to fit various shapes and sizes. Ultimately, steel wire mesh proves to be a trustworthy and efficient option for sunshade purposes.

- Q: Can steel wire mesh be used for insect control?

- Indeed, insect control can be achieved through the utilization of steel wire mesh. Renowned for its robustness and resilience, steel wire mesh proves to be a highly efficient deterrent against insects. Whether affixed to windows, doors, vents, or any other apertures, it serves the purpose of barring insects from infiltrating a given area. The mesh's minute gaps facilitate the circulation of air while effectively excluding mosquitoes, flies, bees, and other bothersome pests. Furthermore, the corrosion and weather resistance inherent in steel wire mesh guarantees a durable and enduring solution for insect control.

- Q: How is steel wire mesh typically installed?

- To install steel wire mesh, one must first properly prepare the installation area. This involves cleaning the surface and ensuring it is clear of any debris or obstacles that could hinder the installation process. Next, the mesh should be measured and cut to the desired dimensions with precision. It is crucial to ensure an accurate fit for the intended space. After preparing the mesh, it can be affixed to the desired structure or framework using various methods, such as welding, stapling, or tying. The chosen method depends on the application and the strength required for installation. In certain cases, additional support structures or frames may be necessary to enhance the stability of the steel wire mesh. These supports can be installed before or during the mesh installation, depending on the specific project requirements. Finally, once the mesh is securely attached, it is essential to inspect the installation for proper alignment, tautness, and absence of visible defects. This step is critical to guarantee the durability and effectiveness of the steel wire mesh installation. In summary, the successful and long-lasting installation of steel wire mesh necessitates careful preparation, precise cutting, secure attachment, and meticulous inspection.

Send your message to us

Welded Wire Mesh for Chicken Fence-1 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords