Welded Wire Mesh for Glasswool -5/8 X 5/8

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

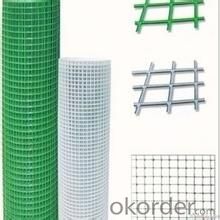

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to impact or abrasion?

- Yes, steel wire mesh is generally resistant to both impact and abrasion. Steel wire mesh is known for its strength and durability, making it highly resistant to impact. It can withstand the force of heavy objects or external pressure without breaking or deforming easily. Similarly, steel wire mesh is also highly resistant to abrasion. The tightly woven steel wires create a solid and sturdy surface that can withstand friction and wear over time. This makes steel wire mesh a suitable material for various applications that require protection against impact or abrasion, such as fencing, reinforcement in concrete structures, or industrial filters.

- Q: Can steel wire mesh be used for gutter guards?

- Certainly! Gutter guards can indeed utilize steel wire mesh. This sturdy and resilient material effectively obstructs the entry of leaves, debris, and other solid particles into the gutter system. By placing it over the top of the gutter, a protective barrier is formed that permits water to flow through while obstructing larger objects. Due to its rust and corrosion resistance, steel wire mesh proves to be a durable choice for safeguarding gutters. Nonetheless, it is crucial to ensure that the mesh possesses a sufficiently fine grid size to prevent the passage of small debris. Additionally, regular maintenance and cleaning may still be necessary to maintain the optimal functionality of the gutter guards.

- Q: Can steel wire mesh be used for retaining rock walls?

- Yes, steel wire mesh can be used for retaining rock walls. Steel wire mesh is commonly used in various construction applications, including retaining walls. When properly installed, it provides additional support and stability to the rock wall by acting as a reinforcement. The wire mesh helps to prevent the rocks from shifting or sliding, enhancing the overall strength and durability of the wall. Additionally, steel wire mesh is resistant to corrosion, making it a suitable choice for outdoor applications where it may be exposed to moisture and other environmental factors.

- Q: Is steel wire mesh suitable for use in agricultural fencing?

- Yes, steel wire mesh is suitable for use in agricultural fencing. It is a durable and strong fencing material that can effectively contain livestock, protect crops from grazing animals, and prevent unauthorized entry into agricultural areas. Steel wire mesh is resistant to weather conditions, such as wind and rain, and can withstand the pressure exerted by large animals. It is also highly versatile, as it can be easily installed and adjusted according to specific fencing needs. Additionally, steel wire mesh provides good visibility, allowing farmers to monitor their livestock and crops easily. Overall, steel wire mesh is a popular choice for agricultural fencing due to its durability, strength, versatility, and effectiveness in protecting agricultural areas.

- Q: How does the weave pattern affect the performance of steel wire mesh?

- The performance of steel wire mesh is greatly influenced by its weave pattern, which impacts its strength, durability, and functionality. The weave pattern refers to how the wires are arranged and interlocked in the mesh structure. To begin with, the tensile strength and load-bearing capacity of the steel wire mesh are determined by its weave pattern. Different patterns, such as plain, twill, or Dutch weave, result in varying levels of strength. For instance, a plain weave pattern evenly distributes the load across the wires, making it suitable for applications with moderate strength requirements. In contrast, a Dutch weave pattern, with thicker warp wires and a tighter weave, offers higher strength and resistance to heavy loads. Moreover, the weave pattern affects the durability and resistance to wear and tear of the steel wire mesh. The specific interlocking arrangement of the wires creates a stable and sturdy structure. Certain patterns, like twill weave or reverse plain weave, increase durability by minimizing the risk of unraveling or fraying. These patterns are ideal for applications involving constant movement or friction, such as filtration systems or conveyor belts. Additionally, the functionality of the steel wire mesh for specific applications is influenced by the weave pattern. Different patterns provide varying levels of openness, flexibility, or filtration capabilities. For example, a plain weave pattern with evenly spaced wires is commonly used for window screens to allow sufficient airflow while keeping insects out. On the other hand, a twill weave pattern with closely spaced wires is often used for sieving or filtering applications that require a fine mesh to separate particles. In conclusion, the weave pattern of steel wire mesh plays a critical role in determining its performance. It impacts its strength, durability, and functionality, making it suitable for specific applications with different requirements. Therefore, selecting the appropriate weave pattern is essential to ensure optimal performance and longevity of the steel wire mesh in its intended use.

- Q: Can steel wire mesh be electroplated?

- Yes, steel wire mesh can be electroplated. Electroplating is a process that involves depositing a thin layer of metal onto the surface of an object through an electrochemical reaction. Steel wire mesh can be electroplated by immersing it in an electrolyte solution containing metal ions of the desired plating material, such as nickel or chromium, and passing an electric current through the solution. The electric current causes the metal ions to be attracted to the steel wire mesh, forming a metallic coating on its surface. This electroplating process can provide various benefits to the steel wire mesh, including enhanced corrosion resistance, improved aesthetics, and increased durability.

- Q: Can steel wire mesh be used for outdoor applications?

- Yes, steel wire mesh can be used for outdoor applications. It is commonly used for fencing, security, and reinforcement purposes due to its strength, durability, and resistance to harsh weather conditions.

- Q: What are the different mesh opening shapes available for steel wire mesh?

- There are several different mesh opening shapes available for steel wire mesh, each with its own unique characteristics and applications. Some of the most common shapes include: 1. Square: This is the most basic and common mesh opening shape. It features straight wires arranged in a square grid pattern, with equal spacing between the wires. Square mesh openings provide good visibility and airflow, making them suitable for various applications such as fencing, window screens, and machinery guards. 2. Rectangular: Similar to square mesh, rectangular openings have straight wires arranged in a rectangular grid pattern. The longer and narrower openings make this type of mesh ideal for applications where greater strength and support are required, such as in construction, reinforcing concrete, and filtration. 3. Diamond: Diamond-shaped mesh openings have diagonally crossing wires, creating a diamond pattern. This type of mesh offers high tensile strength and is commonly used in heavy-duty applications, including mining, agriculture, and security fencing. 4. Hexagonal: Hexagonal mesh, also known as chicken wire, has hexagon-shaped openings formed by twisted wires. This type of mesh is lightweight and flexible, making it suitable for applications such as animal enclosures, poultry netting, and erosion control. 5. Welded: Welded wire mesh consists of intersecting wires that are welded together at each intersection. It can be manufactured with various opening shapes, including square, rectangular, and diamond. Welded mesh is known for its strength and durability, making it widely used in construction, industrial settings, and concrete reinforcement. 6. Expanded: Expanded metal mesh is created by cutting and stretching a solid sheet of metal, resulting in diamond-shaped openings. This mesh offers excellent strength-to-weight ratio and is commonly used in architectural applications, walkways, platforms, and filtration. 7. Woven: Woven wire mesh is created by interweaving wires in an over-under pattern. It can be manufactured with various opening shapes, including square, rectangular, and diamond. Woven mesh is versatile and can be used in a wide range of applications, including screening, separation, and insect protection. These are just a few examples of the different mesh opening shapes available for steel wire mesh. The choice of shape depends on the specific requirements of the application, including strength, visibility, airflow, and particle retention.

- Q: Is steel wire mesh suitable for playground equipment?

- Yes, steel wire mesh is suitable for playground equipment. It provides durability, strength, and safety, making it ideal for various applications such as climbing structures, safety fencing, and play area enclosures. The mesh design ensures proper ventilation and visibility while maintaining a secure environment for children to play.

- Q: What are the installation requirements for steel wire mesh?

- The installation requirements for steel wire mesh typically include preparing a suitable surface, ensuring proper anchoring or attachment points, and securing the mesh tightly to prevent sagging or shifting. Additionally, it is important to follow any specific instructions provided by the manufacturer and to consider factors such as temperature, load capacity, and exposure to corrosive or abrasive environments.

Send your message to us

Welded Wire Mesh for Glasswool -5/8 X 5/8

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords