Welded Wire Mesh for Building -1/2 X 1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

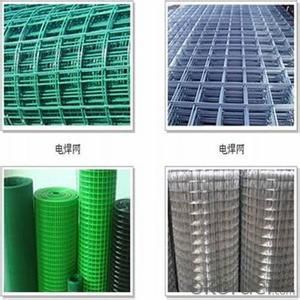

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How does steel wire mesh perform in electrical conductivity?

- Steel wire mesh is not a good conductor of electricity. While steel is a metal and generally conducts electricity well, the presence of a mesh structure in the steel wire reduces its conductivity. The mesh structure creates numerous gaps and openings in the wire, interrupting the flow of electric current. Additionally, the surface area of the mesh is larger compared to a solid wire, which further hinders the flow of electricity. Therefore, steel wire mesh is not an ideal material for applications that require high electrical conductivity.

- Q: Can steel wire mesh be used for speaker cabinets?

- Yes, steel wire mesh can be used for speaker cabinets. Steel wire mesh is a versatile material that offers several benefits when used in speaker cabinets. It provides a protective barrier that prevents foreign objects from entering the cabinet and damaging the speaker components. Additionally, it allows sound to pass through easily, ensuring optimal audio performance. Steel wire mesh is also durable and long-lasting, making it a suitable choice for speaker cabinets that need to withstand regular use and potential impacts. Ultimately, the use of steel wire mesh in speaker cabinets can enhance both the functionality and aesthetics of the speakers.

- Q: What are the benefits of using steel wire mesh in the telecommunications industry?

- There are several benefits of using steel wire mesh in the telecommunications industry. Firstly, steel wire mesh offers excellent durability and strength, making it ideal for outdoor applications such as telecommunications infrastructure. It can withstand harsh weather conditions, extreme temperatures, and strong winds, ensuring the longevity and reliability of the network. Moreover, steel wire mesh provides excellent protection against external threats. It acts as a physical barrier, preventing unauthorized access and vandalism, which is crucial for securing sensitive telecommunications equipment. Additionally, the mesh structure allows for visibility and monitoring, enabling technicians to easily inspect and maintain the equipment without compromising security. Another advantage of steel wire mesh is its ability to provide electromagnetic shielding. Telecommunications equipment often generates electromagnetic fields, and steel wire mesh can effectively contain and redirect these fields, reducing interference and improving signal quality. This shielding property is particularly important in densely populated areas where multiple networks and devices coexist. Furthermore, steel wire mesh is highly flexible and can be easily customized to fit various shapes and sizes, making it suitable for a wide range of applications in the telecommunications industry. It can be used to enclose antennas, cabinets, control rooms, and other equipment, providing a versatile solution for different infrastructure needs. Lastly, steel wire mesh is a cost-effective option for the telecommunications industry. It requires minimal maintenance, reducing operational expenses in the long run. The durability and longevity of steel wire mesh also lead to fewer replacements and repairs, resulting in cost savings for network operators. In conclusion, the benefits of using steel wire mesh in the telecommunications industry include durability, security, electromagnetic shielding, flexibility, and cost-effectiveness. Its properties make it an ideal choice for protecting and maintaining telecommunications infrastructure, ensuring reliable and efficient communication networks.

- Q: What are the main applications of steel wire mesh?

- Due to its durability, strength, and versatility, steel wire mesh finds a wide range of applications. The primary uses of steel wire mesh include: 1. Construction: In the construction industry, steel wire mesh is extensively employed to reinforce concrete structures like walls, columns, and foundations. It imparts strength and stability to the concrete, enhancing its resistance to cracks and structural failures. 2. Fencing and security: Steel wire mesh is widely utilized for fencing purposes, be it for residential, commercial, or industrial settings. It forms a robust barrier that is challenging to breach, thereby enhancing security and privacy. Moreover, steel wire mesh is frequently employed in high-security areas such as prisons or military installations to prevent unauthorized access. 3. Filtration and separation: Various filtration systems utilize steel wire mesh to separate or filter different substances. It is commonly employed in industrial applications such as oil and gas, mining, and wastewater treatment. The mesh size and shape can be customized to meet specific filtration requirements, ensuring efficient separation of solids and liquids. 4. Animal enclosures and cages: In zoos, veterinary clinics, and farms, steel wire mesh is often employed to create animal enclosures and cages. It provides a secure and durable barrier while allowing proper ventilation and visibility. Additionally, steel wire mesh can be galvanized or coated to resist corrosion and withstand harsh weather conditions. 5. Landscaping and gardening: Steel wire mesh is commonly used in landscaping and gardening applications. It can be utilized to create trellises for climbing plants, support structures for vegetable gardens, or to protect plants from pests. The durability and strength of steel wire mesh make it suitable for outdoor use, even in areas with harsh weather conditions. 6. Industrial storage and shelving: Steel wire mesh is frequently employed in industrial storage systems like pallet racking and shelving units. It provides a strong and stable platform for storing heavy items, thereby increasing storage capacity and organization. The open design of the mesh allows for airflow, reducing the risk of moisture buildup and corrosion. In conclusion, steel wire mesh is an adaptable material with a multitude of applications. Its strength, durability, and customization options make it ideal for construction, fencing, filtration, animal enclosures, landscaping, and industrial storage.

- Q: Can steel wire mesh withstand high temperatures?

- Steel wire mesh has the capability to endure high temperatures. Typically, stainless steel or carbon steel is used in the production of steel wire mesh. Both of these materials possess high melting points and exceptional resistance to heat. Stainless steel wire mesh can withstand temperatures ranging from 800-900 degrees Celsius (1472-1652 degrees Fahrenheit), whereas carbon steel wire mesh can endure temperatures up to 450-500 degrees Celsius (842-932 degrees Fahrenheit). Consequently, steel wire mesh is ideal for various high-temperature applications, including industrial furnaces, kilns, and heat treatment processes. However, it is crucial to acknowledge that the temperature resistance of steel wire mesh may differ depending on the grade and quality of the steel utilized, as well as the specific manufacturing techniques employed. Therefore, it is advisable to consult the manufacturer or supplier for accurate temperature ratings and suitability concerning particular high-temperature applications.

- Q: Can steel wire mesh be painted?

- Yes, steel wire mesh can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion and durability of the paint. Firstly, the mesh should be thoroughly cleaned to remove any dirt, grease, or rust. A wire brush or sandpaper can be used to smooth out any rough edges or rust spots. After cleaning, it is recommended to apply a primer specifically designed for metal surfaces to promote better paint adhesion and prevent corrosion. Once the primer has dried, you can proceed to paint the steel wire mesh using a paint suitable for metal applications. It is important to follow the manufacturer's instructions for the paint and allow sufficient drying time between coats. Overall, with proper preparation and the right type of paint, steel wire mesh can be successfully painted to achieve the desired appearance and protection.

- Q: What are the benefits of using steel wire mesh in the chemical recycling industry?

- Steel wire mesh offers several benefits in the chemical recycling industry. Firstly, it provides strength and durability, making it suitable for handling and storing chemicals safely. Additionally, steel wire mesh is resistant to corrosion, ensuring longevity and preventing contamination of the recycled materials. Its open and porous structure allows for efficient airflow and drainage, facilitating the drying process of chemical waste. Moreover, steel wire mesh is easy to clean and maintain, reducing the risk of cross-contamination and ensuring the purity of the recycled products. Overall, the use of steel wire mesh enhances safety, efficiency, and quality in the chemical recycling industry.

- Q: Why hung wire mesh can play the role of anti-cracking?

- Why is the reinforced concrete stronger than the brick, because there are steel bars. Popular point, when the mortar in the drying process to crack the release of stress, the steel wire mesh and mortar has been fixed in a fixed,

- Q: What are the different types of steel wire mesh?

- There are several types of steel wire mesh, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Each type has its own unique characteristics and applications. Welded wire mesh is made by welding individual wires together to form a grid pattern, providing strength and durability. Woven wire mesh is created by weaving individual wires together in an interlocking pattern, making it flexible and versatile. Expanded metal mesh is produced by cutting and stretching a sheet of metal, creating diamond-shaped openings, which offer excellent ventilation and visibility. Perforated metal mesh is made by punching holes into a metal sheet, allowing for airflow, light transmission, and sound absorption.

- Q: Can steel wire mesh be used for creating safety nets?

- Yes, steel wire mesh can be used for creating safety nets. Steel wire mesh is a strong and durable material that can effectively prevent falls and provide a protective barrier. It is commonly used in construction sites, sports facilities, and other areas where safety is crucial.

Send your message to us

Welded Wire Mesh for Building -1/2 X 1/2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords