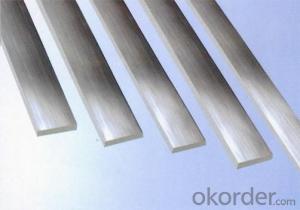

1/2 X 1/2 Aluminum Bar Stock

1/2 X 1/2 Aluminum Bar Stock Related Searches

1/2 Aluminum Bar Stock 1/2 X 3/4 Aluminum Bar Stock 1 X 2 Aluminum Bar Stock 1 2 X 1 2 Aluminum Bar Stock 1/2 Inch Aluminum Flat Stock 1/4 X 1/4 Aluminum Bar Stock 1/4 Aluminum Bar Stock Aluminum Half Round Bar Stock 1 2 Aluminum Bar Stock 1 1/2 Aluminum Round Stock 3/4 Aluminum Bar Stock 2 Aluminum Bar Stock 1 2 X 3 4 Aluminum Bar Stock 2 Inch Aluminum Bar Stock 3/8 Aluminum Bar Stock Aluminum Bar Stock 1 2 1 Inch Aluminum Bar Stock 1/2 Aluminum Plate 3/4 X 3/8 Aluminum Bar Stock 1 Aluminum Bar Stock Aluminum 1/2 Plate 1 4 X 1 4 Aluminum Bar Stock 1/2 Inch Aluminum Plate 1 8 X 1 Aluminum Bar Stock 1/2 In Aluminum Plate 1 4 Inch Aluminum Bar Stock 1 8 X 1 4 Aluminum Bar Stock 1/2 Thick Aluminum Plate Stock Aluminum Bar 1 4 Aluminum Bar Stock1/2 X 1/2 Aluminum Bar Stock Supplier & Manufacturer from China

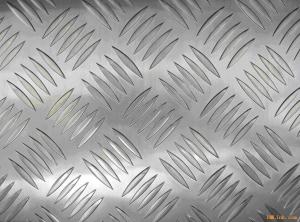

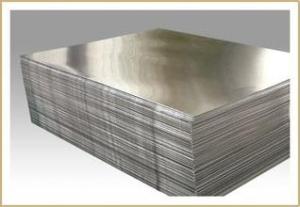

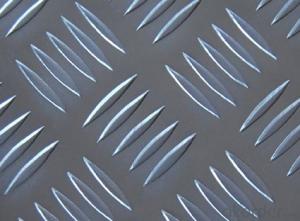

The 1/2 X 1/2 Aluminum Bar Stock is a popular choice among various industries for its lightweight and high strength properties. This aluminum bar stock is available in different grades, offering a wide range of applications and usage scenarios. It is commonly used in construction, aerospace, automotive, and other industries where lightweight and durable materials are required. The 1/2 X 1/2 Aluminum Bar Stock is also known for its excellent corrosion resistance and ease of fabrication, making it a preferred choice for many engineers and designers.The 1/2 X 1/2 Aluminum Bar Stock is widely used in applications such as structural components, brackets, frames, and other load-bearing parts. Its versatility allows it to be used in both commercial and industrial settings, providing a reliable and efficient solution for various projects. The aluminum bar stock can be easily machined, bent, and welded, making it a convenient material for a multitude of applications. Additionally, its non-magnetic properties make it suitable for use in environments where magnetic interference is a concern.

Okorder.com is a leading wholesale supplier of 1/2 X 1/2 Aluminum Bar Stock, offering a vast inventory of this high-quality product. As a reputable supplier, Okorder.com ensures that customers receive the best possible prices and service. With a commitment to customer satisfaction, Okorder.com provides a seamless purchasing experience, making it easy for clients to find and order the 1/2 X 1/2 Aluminum Bar Stock they need for their projects. By partnering with Okorder.com, customers can be confident that they are receiving a reliable and cost-effective solution for their aluminum bar stock requirements.

Hot Products