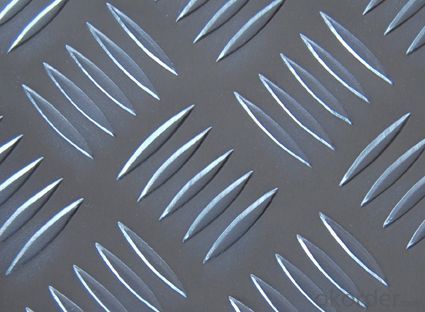

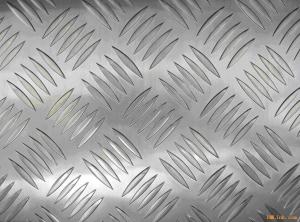

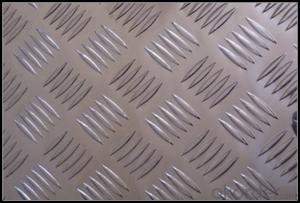

Aluminum Sheets for Sale 06 - Al Sheet Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Finishing:Mill Finish, Painted, One Side Bright, Brushed and Coil Anodizing available onrequest

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper:H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm(Can be slitted)

Standard:GB/T 3880-2006 ASTM B-209

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Can aluminum plate resist acid and alkali?

- Aluminum is a more active metal, easy to react with the acid and alkali of the outside world. If it is in water for a long time, aluminum will react with acid and alkali substances in water. How to improve the acid and alkali resistance of aluminum alloy?Mainly through the oxidation of aluminum alloy, so that its surface with a layer of oxide film, to prevent the external acid-base substances on aluminum alloy corrosion.In order to reduce the surface hardness and wear resistance of aluminum alloy and prolong its service life, the surface oxidation surface treatment technology has become an indispensable part of the use of aluminum alloy.

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- If not missing the cost or use aluminum plate, because the fluorine content of fluorocarbon metal paint paint factory production lot are not enough, so the warranty 10-15 years is just a pretext, and the construction of the technical requirements for workers is relatively high.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- Chemical transfer piping cannot rely on 101 aluminum sheets as they are unsuitable. The reactivity and corrosion propensity of aluminum make it generally unfit for handling specific chemicals. Industries like aerospace or construction prefer aluminum due to its lightweight nature and excellent thermal conductivity. However, for chemical transfer piping, it is wiser to opt for materials that possess corrosion resistance and can endure the specific chemicals being transported. Stainless steel, PVC, or high-density polyethylene (HDPE) are recommended alternatives.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically classified as Class A, indicating a high level of fire resistance.

- Q: How do you clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, start by rinsing them with water to remove any loose dirt or debris. Then, prepare a mixture of mild dish soap and warm water. Use a soft cloth or sponge to gently scrub the aluminum sheets with the soapy solution, paying attention to any stains or marks. Rinse thoroughly with clean water and dry the sheets using a clean towel or allow them to air dry. To maintain the shine and prevent oxidation, you can apply a thin layer of aluminum polish or a non-abrasive metal cleaner occasionally. Avoid using harsh chemicals or abrasive scrubbers that may cause scratches or damage to the surface.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used as reflective insulation. Aluminum has excellent reflective properties, allowing it to reflect heat and light effectively. This makes it a suitable material for insulating applications where reflecting radiant heat is desired, such as in roofs, walls, or attics.

- Q: This question asks for an explanation of the various grades of aluminum sheets and the distinctions between them.

- <p>Aluminum sheets are categorized into different grades based on their alloy composition, which affects their properties such as strength, formability, and corrosion resistance. Common grades include 1000 series (99.00% aluminum, soft and malleable), 2000 series (aluminum-copper alloys, strong and heat treatable), 3000 series (aluminum-manganese alloys, good formability), 5000 series (aluminum-magnesium alloys, good strength and corrosion resistance), and 6000 series (aluminum-silicone-magnesium alloys, good strength and extrudability). Each grade has specific applications based on its characteristics, with 1000 series used for general purposes, 2000 series for aircraft structures, 3000 series for decorative applications, 5000 series for marine environments, and 6000 series for structural components.</p>

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application it is being used for. Generally, aluminum sheets have a relatively high fatigue strength compared to other materials, allowing them to withstand a large number of cyclic loading cycles before failure. However, it is important to note that fatigue life can be influenced by various factors such as stress levels, loading conditions, and environmental factors like temperature and humidity. Aluminum sheets may experience a decrease in fatigue life when subjected to high stress levels, cyclic loading, or harsh environmental conditions. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an infinite fatigue life. On the other hand, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a finite fatigue life that can range from thousands to millions of cycles. To determine the precise fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more accurate information based on the specific parameters and conditions of use.

Send your message to us

Aluminum Sheets for Sale 06 - Al Sheet Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords