Laserit Laserable Aluminum Sheets - Aluminum Sheet Diamante Embossed

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Sheet Diamante Embossed Description:

Our product is coated with high-performance fluorocarbon, polyester, polyurethane and epoxy coating, and is widely used for roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses.

Main Features of the Aluminum Sheet Diamante Embossed:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

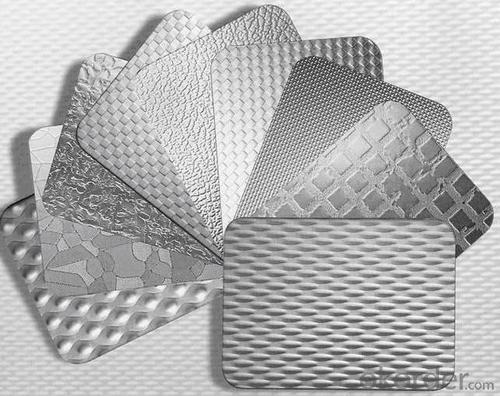

Images of Aluminum Sheet Diamante Embossed:

Aluminum Sheet Diamante Embossed Specification:

Other Product | Alloy | Temper | Thickness(mm) | Width (mm) | Length (mm) |

Aluminum tread plate | 1100 1050 1060 | O H12 H14 H16 H18 H22 H24 H26 H32 H36 H111 H112

| 0.2-200 | 40-1450 | As your requirement |

3003 3004 3005 3105 | |||||

5005 5754 5052 | |||||

5086 | |||||

6061 8011 |

FAQ of Aluminum Sheet Diamante Embossed:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: 1mm aluminum sheet, stamping, die opening, how much is it?

- According to your needs, there are two practices:1, the official commodity mold, using 4-8 tons of punch or cylinder as a power to suppress, so that the mold should be around 2000 yuan.2, the use of simple mold, direct processing of an upper mold, a lower die, probably costs around 500 yuan. Or cheaper.

- Q: Can the aluminum sheets be used for manufacturing power transmission lines?

- Power transmission lines can be manufactured using aluminum sheets. Aluminum possesses several properties that make it suitable for this purpose. To begin with, aluminum is a lightweight material, making it more convenient to handle and transport compared to metals like copper. This can lead to reduced installation costs and increased efficiency of the power transmission lines. Additionally, aluminum exhibits good electrical conductivity, although it may not be as conductive as copper. However, due to its lighter weight, aluminum can still achieve similar electrical performance to copper while using less material. This can result in cost savings and reduced energy losses in the transmission lines. Moreover, aluminum demonstrates excellent resistance to corrosion, which is vital for power transmission lines that are frequently exposed to different weather conditions and environmental factors. Aluminum can endure harsh conditions and maintain its structural integrity over time, ensuring the reliability and longevity of the power transmission infrastructure. To conclude, aluminum sheets can indeed be utilized for the manufacturing of power transmission lines due to their lightweight nature, favorable electrical conductivity, and outstanding corrosion resistance.

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: What are the different types of surface treatments available for aluminum sheets?

- There are several different types of surface treatments available for aluminum sheets, each serving a specific purpose and providing unique characteristics. Some of the most common surface treatments for aluminum sheets include anodizing, painting, powder coating, and polishing. Anodizing is a process that involves the formation of a thick oxide layer on the surface of the aluminum sheet. This treatment not only enhances the appearance of the sheet by providing a variety of colors, but also improves its corrosion resistance and durability. Anodized aluminum sheets are widely used in architectural applications, automotive parts, and electronics. Painting is another popular surface treatment for aluminum sheets. It involves applying a layer of paint on the surface to enhance its appearance and provide additional protection against corrosion and wear. Painted aluminum sheets are commonly used in signage, building facades, and decorative applications. Powder coating is a type of surface treatment that involves applying a dry powder to the aluminum sheet and then heating it to create a protective layer. This treatment offers excellent durability, resistance to weathering, and a wide range of color options. Powder coated aluminum sheets are commonly used in the construction industry, as well as for automotive parts and appliances. Polishing is a surface treatment that involves buffing the aluminum sheet to create a smooth and reflective surface. This treatment enhances the aesthetics of the sheet, making it ideal for decorative applications such as furniture, jewelry, and architectural accents. Overall, the choice of surface treatment for aluminum sheets depends on the desired appearance, functionality, and application requirements. Each treatment offers unique benefits and characteristics, allowing for versatility and customization in various industries.

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Yes, aluminum sheets are suitable for manufacturing window frames.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. They are commonly used for packaging pharmaceutical products due to their excellent barrier properties, lightweight nature, and resistance to corrosion. Aluminum sheets help to protect the contents from moisture, oxygen, and light, ensuring the stability and effectiveness of pharmaceutical drugs. Additionally, aluminum sheets can be easily formed into different shapes, making them ideal for creating blister packs, caps, and closures for pharmaceutical packaging.

- Q: Can aluminum sheets be welded or joined together?

- Indeed, welding or joining together aluminum sheets is possible. Aluminum possesses excellent weldability, allowing for its fusion through diverse welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These methods involve the application of heat to liquefy the aluminum sheets and establish a robust connection. Furthermore, mechanical fasteners like screws, rivets, or adhesive bonding can also be employed to join aluminum sheets. The selection of the welding or joining approach hinges upon the particular application and the desired result.

Send your message to us

Laserit Laserable Aluminum Sheets - Aluminum Sheet Diamante Embossed

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords