Aluminium Composite Panel Facade Decoration-BEST QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

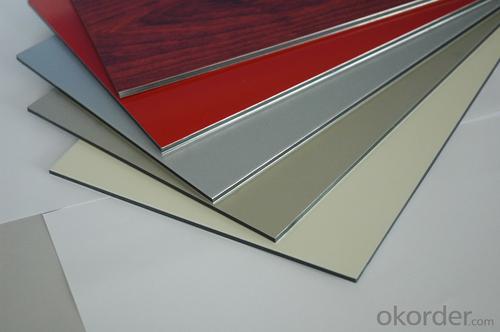

Structure of ACP Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

Main Features of ACP:

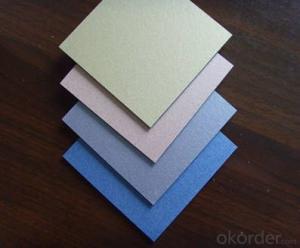

1) Super werther resistance

2) Light weight easy to process

3) Excellent fire resistance

4) Excellent impact strength

5) Uniform and colorful coating

6) Easy maintenance...and so on

7) Within 15 work days after receiving the first deposite payment .

Images of ACP:

ACP Specifications:

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Accepted Width | Max:1580mm |

Accepted Length | Max:6000mm |

Accepted Thickness | 2mm,3mm,4mm,5mmm,6mm |

Aluminum alloy thickness | 0.10mm0.15mm0.18mm0.21mm0.25mm0.3mm0.35mm0.40mm0.45mm0.50mm |

Weight | 5 kg/m2 base on 4*0.4mm |

Nonstandard | sizes are available according your requirement |

FAQ of ACP:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

Uses of Aluminum

Aluminum is one of the most useful metals on the planet. Uses of this metal, especially the sheets include industry, technology, and insides homes. In addition to being one of the most useful metals, it is also one of the most common. Everywhere you look you will see aluminum, from aluminum foil in the home to the aluminum bodies of older cars. Aircraft is made out of aluminum and this metal is used to build some buildings as well.

TRANSPORTATION

One of the major categories in which aluminum has a very large influence is in the transportation sector. This metal has many uses in the transportation sector because of its flexibility and very high tensile strength. A very common application in which you would see aluminum used in the transportation sector is aircraft. Most aircraft fuselages and wings are made from aircraft-grade aluminum. This metal can withstand the immense pressure changes that most aircraft endure during a typical flight. Sheet aluminum is also widespread throughout the transportation sector and is usually used to construct railroad cars and truck trailers.

HOUSEHOLD

Another area in which aluminum has many uses is inside the home. One of the most prominent items inside most homes that is made of aluminum is aluminum foil and aluminum sheets.Aluminum foil itself has thousands of applications inside a typical household, such as storing leftover food, making decorations, packing food, and insulating plumbing and electrical work. More uses of aluminum inside the home include some eating utensils, baseball bats, watches and even cooking utensils. Since aluminum has almost no toxicity after processing, it is quite safe to use it in objects that will be put inside the human body, such as eating and cooking utensils, as well as pots and pans.

INDUSTRY

Aluminum has many uses in heavy industry because it can be made in a variety of thicknesses and it also is semi-conductive and reflective of heat and light. This metal is also waterproof after a thickness of greater than one millimeter and therefore can be used to keep liquid out of certain materials and it is also used inside many different consumer electronics devices.

Uses of aluminum are great and they vary depending upon the application being used. This metal can often be found inside homes in the form of aluminum foil, but it is also present on construction sites, inside manufacturing facilities, and inside the electronics that consumers use on an everyday basis.

- Q: What is aluminium oxide sheet?

- The oxidation of aluminum in natural and chemical oxidation, and oxidation of several, generally refers to the chemical oxidation oxidation plate plate, is the use of chemical reaction to aluminum formed on the surface of a white coating can reach the anticorrosion effect, can also be made, through technology, color, color, texture

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

- Q: What are the standard sizes of aluminum sheets?

- Aluminum sheet sizes can differ based on the manufacturer and specific needs. Nevertheless, there are several standard sizes commonly found for aluminum sheets. These include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely utilized across various industries and are easily accessible in the market. Furthermore, specialized aluminum sheet suppliers can provide custom sizes tailored to meet specific project requirements.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets varies depending on the specific alloy used. However, on average, aluminum has a coefficient of thermal expansion of approximately 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). This means that for every degree increase in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It is important to note that this value may slightly differ for different grades and alloys of aluminum.

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: Is it possible to manufacture furniture using aluminum sheets?

- <p>Yes, aluminum sheets can be used to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications. It is commonly used in outdoor furniture, such as patio sets, as well as in modern indoor furniture designs. Aluminum furniture is easy to maintain, has a sleek appearance, and can be an eco-friendly choice due to its recyclability.</p>

- Q: Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Deodorants do not contain aluminum, only antiperspirants do. The aluminum is used to stop sweating from occurring. There are natural antiperspirants (example Tom's of Main) that claim to stop sweat without the use of aluminum. Aluminum based products have been associated with quite a few health problems: Seizures Breast Cancer Alzheimer's Disease Bone Formation Disorders Kidney Problems Hope this helps.

- Q: Can the aluminum sheets be used for manufacturing aircraft landing gears?

- Yes, aluminum sheets can be used for manufacturing aircraft landing gears. Aluminum is commonly used in the aerospace industry due to its lightweight yet strong properties, making it suitable for such critical components like landing gears.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be bent or formed into different shapes through processes such as bending, rolling, or pressing, due to its malleability and ductility.

Send your message to us

Aluminium Composite Panel Facade Decoration-BEST QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords