Decorative Aluminum Sheets - Mill Finish Embossed Diamond Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Embossed Diamond Aluminum Sheet

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Embossed Diamond Aluminum Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Embossed Diamond Aluminum Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

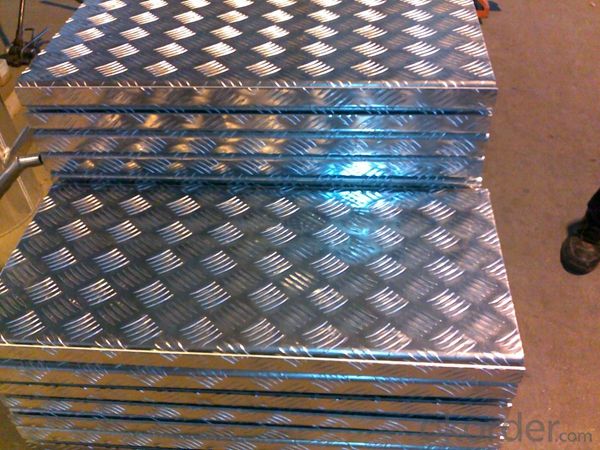

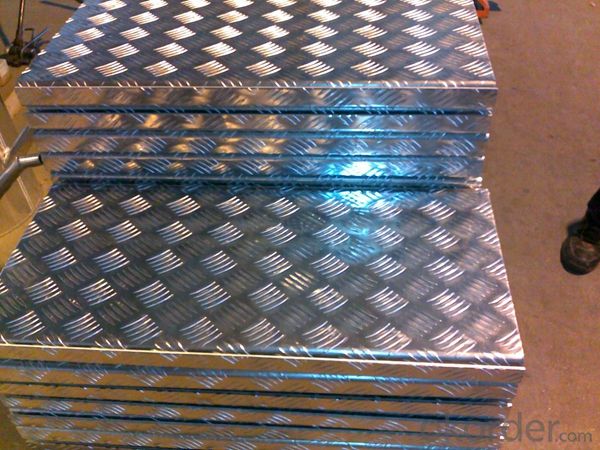

5. Image of Mill Finish Embossed Diamond Aluminum Sheet

6. Package and shipping of Mill Finish Embossed Diamond Aluminum Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors.

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Yes, aluminum sheets are suitable for manufacturing lighting fixtures. Aluminum is a lightweight and versatile material that offers several advantages for lighting fixture manufacturing. Firstly, aluminum is known for its excellent thermal conductivity, meaning it can effectively dissipate heat generated by the lighting components. This helps in prolonging the lifespan of the lighting fixtures and maintaining their efficiency. Additionally, aluminum is corrosion-resistant, which is crucial for lighting fixtures as they are often exposed to different environmental elements. This property ensures that the fixtures will not degrade over time and can withstand outdoor conditions. Moreover, aluminum sheets can be easily formed into various shapes and sizes, allowing manufacturers to create customized designs for lighting fixtures. This versatility makes aluminum an ideal choice for both functional and aesthetic lighting applications. Furthermore, aluminum is a sustainable and eco-friendly material. It is recyclable, reducing the environmental impact of manufacturing processes. This makes aluminum sheets a popular choice for manufacturers that prioritize sustainability in their operations. Overall, the excellent thermal conductivity, corrosion resistance, versatility, and sustainability of aluminum sheets make them highly suitable for manufacturing lighting fixtures.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Medical equipment can be manufactured using aluminum sheets, as they possess several properties that make them appropriate for this purpose. Aluminum is widely utilized in various industries, including healthcare, due to its versatility. To begin with, aluminum is both lightweight and durable, which is advantageous for the production of portable medical devices. This characteristic facilitates the handling and transportation of equipment, particularly for healthcare professionals who may need to move them frequently. Additionally, aluminum exhibits exceptional resistance to corrosion, rendering it suitable for medical applications where cleanliness and hygiene are paramount. It can endure disinfection processes without suffering any deterioration, thus ensuring the longevity of the equipment. Moreover, aluminum can be easily sterilized, which is crucial for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without experiencing any detrimental effects on its structural integrity. Furthermore, aluminum possesses excellent heat and electricity conduction properties. These attributes are beneficial for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is non-toxic, making it safe for medical use. It does not release harmful substances, guaranteeing the absence of health risks to both patients and healthcare professionals. In conclusion, aluminum sheets are indeed suitable for the manufacturing of medical equipment due to their lightweight nature, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, as well as their non-toxicity. These properties make aluminum an appropriate choice for various medical applications, thereby contributing to the advancement of healthcare technology.

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- UV radiation and sunlight can indeed have an impact on aluminum sheets. With the passage of time, the sheets may undergo oxidation due to their exposure to UV radiation and sunlight, resulting in an unsightly and lackluster appearance. Furthermore, extended exposure to UV rays can lead to material weakening, rendering it susceptible to cracking or breakage. To safeguard aluminum sheets from the detrimental consequences of UV radiation, it is advisable to employ a protective coating or opt for anodized aluminum, which boasts a sturdier and longer-lasting surface.

- Q: What are the common applications of aluminum sheets?

- Aluminum sheets are commonly used in various applications such as construction, automotive, aerospace, packaging, and electrical industries. They are used for making lightweight structures, including building facades, roofing, and cladding. In the automotive sector, aluminum sheets are used for manufacturing vehicle bodies and parts due to their high strength-to-weight ratio. They are also utilized in aircraft manufacturing for their low density and corrosion resistance. Additionally, aluminum sheets are popular in packaging as they are lightweight and can be easily formed into different shapes. In the electrical industry, they are used for wiring and conductors due to their excellent conductivity properties.

- Q: Can aluminum sheets be used for pharmaceutical cleanrooms?

- Yes, aluminum sheets can be used for pharmaceutical cleanrooms. Aluminum is a popular choice for cleanroom construction due to its excellent durability, corrosion resistance, and ease of cleaning. It is also non-porous, which helps prevent the growth of bacteria and ensures a sterile environment. Additionally, aluminum sheets can be easily fabricated and installed, making them a suitable material for pharmaceutical cleanroom applications.

- Q: How do aluminum sheets perform in high-temperature environments?

- Due to its exceptional thermal conductivity and relatively low melting point, aluminum sheets are highly effective in high-temperature conditions. With a melting point of 660.3°C (1220.5°F), aluminum is able to endure elevated temperatures without melting, unlike many other metals. Furthermore, its remarkable thermal conductivity enables efficient heat dissipation from the surface, preventing overheating and maintaining the integrity of structures. This quality makes aluminum sheets ideal for applications in industries such as aerospace, automotive, and construction, which often encounter high temperatures. However, it is crucial to acknowledge that prolonged exposure to extremely high temperatures can lead to a weakening of aluminum and a reduction in its mechanical properties. Consequently, in extreme high-temperature environments, it may be necessary to explore alternative materials or implement additional protective measures to ensure optimal performance.

- Q: how to make aluminum products bright? How to polish or clean the products punch formed by 0.3mm aluminum sheet?

- you can try to grind it with magnetic grinder.

- Q: What's the price of the 6mm aluminum sheet?

- The single aluminum plate is aluminum substrate, around the hem (can be customized size and shape) and install bracket forming a mounting edge, the surface of the fluorocarbon coating (various colors can be customized).

Send your message to us

Decorative Aluminum Sheets - Mill Finish Embossed Diamond Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords