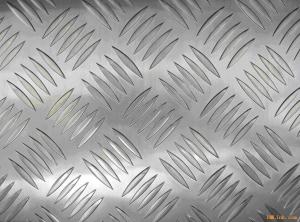

500 Sheets of Aluminum Foil 9 In - Aluminium Two Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum sheet / plate

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration,

Auto radiator, Food container, Aluminum ceiling, Battery shell, LED Lighting, Kitchen rinse bath,

lamp shade , heat exchanger, nameplate, Power transformer, pallet etc.

CHEMICAL COMPOSITION

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

Product Information

Aluminum sheet is usually according to the following two points:

1. According to the alloy composition is divided into:

High purity aluminum plate rolling (by the content above 99.9 high purity aluminum)

Pure aluminum plate (ingredients made from pure aluminum rolling)

Alloy aluminum plate (composed of aluminum alloy and auxiliary, usually with aluminum and copper, aluminum and manganese, aluminum and silicon, aluminum magnesium, etc)

Composite aluminum plate or brazing plate (through a variety of means of material compound special use aluminum material)

Outside package aluminum (aluminum coated aluminum sheet used for special purposes)

2. According to the thickness is divided into: (mm)

Sheet (aluminum sheet) 0.15 to 2.0

Conventional plate (aluminum sheet) 2.0 to 6.0

Medium plate (aluminum plate), 6.0 to 25.0

Plate (aluminum plate) 25-200

Super thick plate more than 200

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Indeed, the utilization of aluminum sheets in the production of chemical piping systems is plausible. Renowned for its remarkable resistance against corrosion, aluminum proves to be apt for handling an array of chemicals. Moreover, its lightweight nature facilitates effortless installation and maintenance procedures. Furthermore, aluminum possesses commendable thermal conductivity, thereby enabling efficient heat transfer within chemical processes. Nonetheless, it is crucial to contemplate the distinctive demands imposed by the chemicals being conveyed and seek guidance from specialists to guarantee the selection of aluminum sheets equipped with indispensable properties and compatibility with the chemicals to be employed within the piping system.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- Let me guess, making thermite? :P The easiest way by far to get aluminum I have found is breaking open an old EtchaSketch. That's aluminum powder in there. There are too many impurities on the can to make it easy, go to the dump and find some old EtchaSketches. Addition: Do NOT breathe in the powder, its not good for your system, it does large amounts of damage to your lungs, I suggest wearing a mask of some sort for safety. Do not take it lightly. Otherwise, have fun melting holes in the ground / someone's car / a safe / anything else you can get your hands on :P

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: What is aluminum curtain wall.

- It's more interesting to use aluminum than to say it's made of glass

- Q: What are the potential safety issues associated with the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use, but there are a few considerations. They can be sharp when cut, so proper handling is important to avoid cuts. Aluminum is a good conductor of heat, so care should be taken to avoid burns when handling hot aluminum sheets. Additionally, inhalation of aluminum dust can be harmful, so it's important to work in a well-ventilated area or use a dust mask when cutting or grinding aluminum. In terms of long-term health, there's ongoing debate about the safety of aluminum exposure, but it's generally considered safe when used in accordance with proper safety measures.</p>

- Q: This question asks for a comparison of the cost of aluminum sheets with other building materials.

- <p>Aluminum sheets are generally considered cost-effective compared to other building materials, especially when considering their long-term benefits. They are relatively inexpensive to produce and install, and their low maintenance requirements can save costs over time. However, their initial cost may be higher than some materials like wood or vinyl. Aluminum's resistance to corrosion and weathering means it lasts longer, which can offset the higher upfront cost. In contrast, materials like steel might be more expensive due to their weight and the cost of corrosion protection, while concrete and masonry are typically more costly for both materials and labor. The cost-effectiveness of aluminum can vary based on regional prices, specific project requirements, and the type of aluminum product (e.g., thickness, finish).</p>

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- You can order it online. It works acceptably well, though it's obviously not as good as bona fide welding. You can also use tin+zinc hard solder, for this- you need a special soldering flux specifically desgined for soldering aluminum. You can order aluminum soldering kits online also. You might also be able to find a welding supply store in your area and they would probably carry Al soldering kits in stock. I feel that soldering would probably give you more reliable results in this case. Solder is a lot thinner and has better wetting action than the durafix alloy. This means that solder will be more likely to flow into the crack itself and completely seal it, whereas the durafix may simply lie on top of the crack. I think durafix technically qualifies as brazing since it melts at a lower temperature than the aluminum itself. However, you will also need to buy a propane torch, that'll probably cost around 30-40$ at a hardware store. Plus the cost of the brazing metal which is around 12-20$. so you're looking at 30-50$ probably. This might be a bit of a fun- DIY project if you feel it's worth some time and practice on your part. On the other hand any welding shop can simply TIG weld your pipe for about 20$ and it will only take them a few minutes. So having the professionals do it will be much faster, cheaper, and almost certainly a better quality repair than if you attempted to DIY.

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

Send your message to us

500 Sheets of Aluminum Foil 9 In - Aluminium Two Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords