1 4 X 1 4 Aluminum Bar Stock

1 4 X 1 4 Aluminum Bar Stock Related Searches

1 4 Inch Aluminum Bar Stock 1 2 X 3 4 Aluminum Bar Stock 1 4 Aluminum Bar Stock 1 8 X 1 4 Aluminum Bar Stock 1/4 X 1/4 Aluminum Bar Stock 1/4 Aluminum Bar Stock 1 X 2 Aluminum Bar Stock 1 2 X 1 2 Aluminum Bar Stock 1 Inch Aluminum Bar Stock 3 4 Aluminum Bar Stock 1 Aluminum Bar Stock 1 8 X 1 Aluminum Bar Stock 1/2 X 3/4 Aluminum Bar Stock 3 4 X 3 8 Aluminum Bar Stock 3/4 Aluminum Bar Stock 1 4 Inch Aluminum Flat Stock 1 2 Aluminum Bar Stock Aluminum Bar Stock 1 2 Stock Aluminum Bar 3/4 X 3/8 Aluminum Bar Stock Aluminum Stock Bar 1 4 Aluminum Flat Stock 1 1 4 Aluminum Round Stock 1 8 Aluminum Bar Stock 1 1/4 Aluminum Round Stock 3/8 Aluminum Bar Stock 1/2 X 1/2 Aluminum Bar Stock 2 Aluminum Bar Stock 1 4 Aluminum Round Stock 1 4 Aluminum Plate1 4 X 1 4 Aluminum Bar Stock Supplier & Manufacturer from China

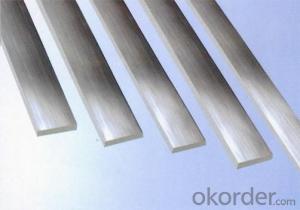

1/4 X 1/4 Aluminum Bar Stock is a type of aluminum material that comes in the form of a rectangular bar with dimensions of 1/4 inch by 1/4 inch. This product is made from high-quality aluminum alloy, which provides excellent strength, durability, and corrosion resistance. It is widely used in various industries for a multitude of applications due to its lightweight and versatile nature.The 1/4 X 1/4 Aluminum Bar Stock is commonly utilized in construction, automotive, aerospace, and manufacturing sectors. It is particularly popular for its use in structural components, brackets, and other load-bearing parts that require high strength-to-weight ratios. Additionally, this aluminum bar stock is suitable for machining and fabrication processes, making it an ideal choice for custom projects and precision engineering tasks.

Okorder.com is a leading wholesale supplier of 1/4 X 1/4 Aluminum Bar Stock, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to providing high-quality materials at competitive prices, Okorder.com ensures that customers receive the best value for their investment. The company's extensive stock allows for quick turnaround times and efficient delivery, making it a reliable choice for businesses seeking a dependable supplier of aluminum bar stock.

Hot Products