Aluminum 4mm Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

best price aluminum 4mm sheet1)Certificate: ISO9001:2008

2)Famous Trademark

3)Size: 1220*2440

4)Coated: PE&PVDF

fireproof aluminium composite panel

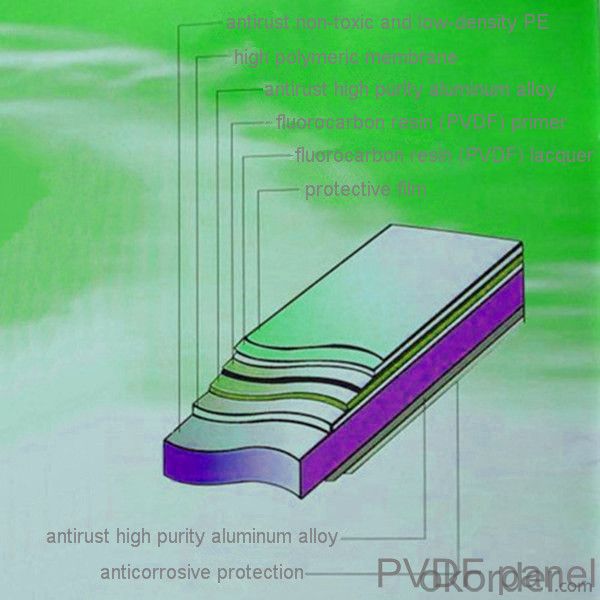

Structure of fireproof aluminium composite panel

1) Two layers of involucres, two layers of aluminum metal;

2) One layer of plastic, one layer anticorrosive;

3) One layer of FLC colophony lacquer, one guard layer.

The use of fireproof aluminium composite panel

1) Building exterior curtain wall, purdah wall;

2) Decoration and renovation additions for old buildings;

3) Decorations of interior walls (ceilings, partitions, bathrooms, cabinet, counter,

video wall, shield for doors windows, skirting, kitchens and balconies.)

4) Shop door decorations;

5) Advertisement board display platforms and signboards;

6) Wallboards and ceilings for tunnels;

7) Industrial materials, material for vehicles and boats;

8) Work stuff, refrigerator car and so on.

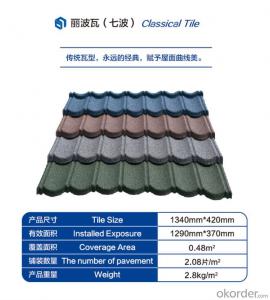

Specifications:

Inside wall:

Size: 3*1220*2440

Al-thickness: 0.06--0.21mm

Outside wall:

Size: 4*1220*2440 5*1220*2440

Al-thickness: 0.06--0.5mm

Length: 2440mm--6000mm, as per customers' request

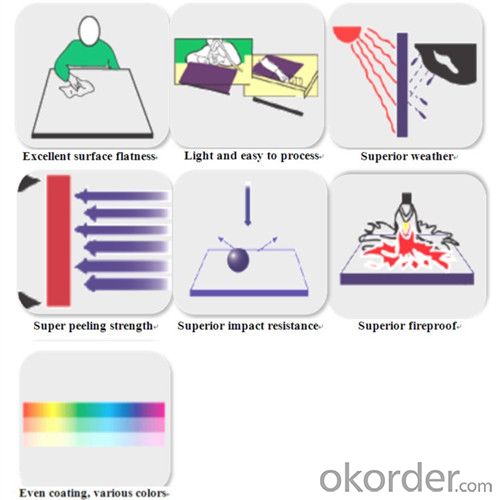

Characteristics of fireproof aluminium composite panel

1) Hardness, easy to care of;

2) Four season for use;

3) Easy to machining and construction;

4) Super peeling strength;

5) Excellent surface flatness and smoothness;

6) Superior weather, corrosion, pollutant resistance;

7) Even coating, various colors;

8) Fireproof, quakeproof, excellent heat and sound insulation;

9) Superior impact resistance;

10) Lightweight, lighten the load of the building;

11) Easy to process, easy to maintain.

The features of fireproof aluminium composite panel

The color code of products

Package:

- Q: My family has been a stock of aromatic smell, has not been clear to find the source of pollution, suspected to be buying the plate furniture, kitchen ceiling is 309 glue stained aluminum-plastic plate, do not know whether this pollution?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q: Standard for aluminum-plastic plates

- Aluminum-plastic plate standard GB / T17748-2008 "building curtain wall with aluminum composite panel" for the external wall panels, the general application of more than 4mm sheet.

- Q: China, there is no sale of Japan is not the Department of aluminum or steel pipe

- The composition of aluminum-plastic composite plate is made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating. Features of aluminum-plastic plate Aluminum-plastic plate is easy to process, forming a good material. But also for the pursuit of efficiency, for the time of the fine products, it can shorten the duration and reduce costs. Aluminum-plastic plate can be cut, cut, slotted, band saw, drilling, processing buried head, you can also cold bending, cold fold, cold rolling, can also riveting, screw connection or glue bonding.

- Q: Want to know the building curtain wall, with aluminum veneer materials and aluminum-plastic plate material, what the pros and cons?

- 0 points do not want to speak

- Q: Aluminum-plastic panel finishes how to make aluminum-plastic plate paste more firmly hold?

- I am not a master of engineering I do not know slightly

- Q: Aluminum-plastic board to install a seamless splicing or leave a gap

- Seamless installation of the relatively high requirements, the four sides of the panel must be very smooth, and each board and the board must be directly connected to straight, smooth to play a seamless effect. Seamless installation: generally do not recommend the installation of large board surface, large surface itself is not 100% of the flat, installed in the light under the light will see a sense of wave side. In addition, we should consider the environmental climate and temperature changes, but also the material itself, thermal expansion and contraction factors.

- Q: What plastic glue can stick with the board?

- Omnipotent can be, some say that special glue, in fact, almost the same ingredients.

- Q: Out of the balcony of the door sets, with the plywood bag to worry about the sun drying fade. Cracking, with aluminum-clad board package is not only good-looking, can you please help out an idea, thank you !!

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: Aluminum plate to install how much money a flat room

- Different regions, the price will be different! I suggest you go to shop around it!

Send your message to us

Aluminum 4mm Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords