4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

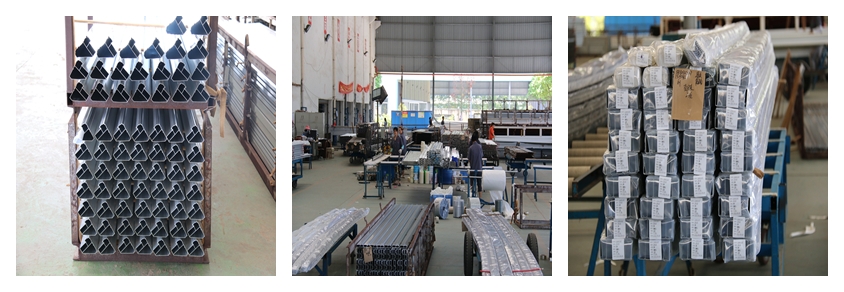

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: Can aluminum sheets be used for air conditioning systems?

- Yes, aluminum sheets can be used for air conditioning systems. Aluminum is a popular material choice for air conditioning components due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It is commonly used for manufacturing air conditioner coils, fins, and heat exchangers.

- Q: Can aluminum sheet be used for heat shielding?

- Yes, aluminum sheet can be used for heat shielding due to its high thermal conductivity and ability to reflect and radiate heat effectively.

- Q: Can aluminum sheets be laser engraved?

- Certainly, it is possible to laser engrave aluminum sheets. Laser engraving proves to be a flexible and accurate technique for marking or engraving diverse materials, among them aluminum. This method entails the utilization of a potent laser beam to eradicate the uppermost layer of the aluminum sheet, thereby forming a permanent and meticulous engraving. In sectors like signage, jewelry, and industrial manufacturing, laser engraving on aluminum sheets is frequently employed for branding, product identification, and decorative aims. The precision and level of intricacy attainable through laser engraving on aluminum sheets vary according to the power and configurations of the laser apparatus utilized.

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

- Q: I would like to make a boat, Songhua River used to know, tell the answer, good + points!

- Marine yacht with 5083, with 5456 of inland water on it, domestic Park boat 5052 will be used

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q: Are aluminum sheets suitable for structural applications?

- Yes, aluminum sheets are suitable for structural applications. They are lightweight, yet strong and durable, making them ideal for various structural uses such as building facades, roofs, and transportation vehicles. Additionally, aluminum sheets have excellent corrosion resistance, which further enhances their suitability for structural applications.

- Q: What industries use aluminum sheets?

- Aluminum sheets are widely used in various industries due to their numerous advantageous properties. One significant industry that utilizes aluminum sheets is the automotive industry. Aluminum is lightweight, yet strong, making it an ideal material for manufacturing car bodies and parts. It helps to reduce the overall weight of the vehicle, thus improving fuel efficiency and reducing emissions. Another industry that heavily relies on aluminum sheets is the aerospace industry. Aluminum's high strength-to-weight ratio makes it suitable for aircraft construction. It is used in the manufacturing of airplane frames, wings, and fuselages. The lightweight nature of aluminum contributes to increased fuel efficiency and allows for larger payloads. The construction industry is also a major consumer of aluminum sheets. Aluminum's corrosion resistance and durability make it an excellent choice for building materials. It is commonly used for roofing, siding, windows, doors, and structural components in both residential and commercial construction projects. In the packaging industry, aluminum sheets are extensively used for the production of beverage cans. Aluminum cans provide a lightweight and portable packaging solution, while also ensuring product freshness and protection from light and air. Furthermore, the electrical industry utilizes aluminum sheets for various applications. Aluminum's excellent conductivity makes it suitable for electrical transmission lines, cables, and wiring. It is also used in the production of heat sinks and electrical enclosures. Other industries that employ aluminum sheets include the marine industry, where it is used for boat building and ship construction due to its resistance to corrosion in saltwater environments. Additionally, aluminum sheets are used in the manufacturing of household appliances, such as refrigerators, ovens, and washing machines, due to their durability, lightweight, and heat conductivity properties. Overall, the versatility, strength, lightweight nature, and corrosion resistance of aluminum sheets make them indispensable in a wide range of industries, including automotive, aerospace, construction, packaging, electrical, marine, and household appliances.

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Aluminum sheets prove to be a fitting option for chemical filtration applications. Renowned for its outstanding corrosion resistance and durability, aluminum emerges as a trustworthy selection for chemical filtration systems. It diligently sieves out impurities and contaminants across diverse chemical procedures, encompassing the separation of solids from liquids and the elimination of hazardous substances. Furthermore, aluminum sheets boast resilience against elevated temperatures and pressures, rendering them well-suited for an extensive array of chemical filtration applications.

Send your message to us

4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords