4' X 8' Aluminum Sheets for Sale - PVDF-Coated Aluminium Composite Panels - Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

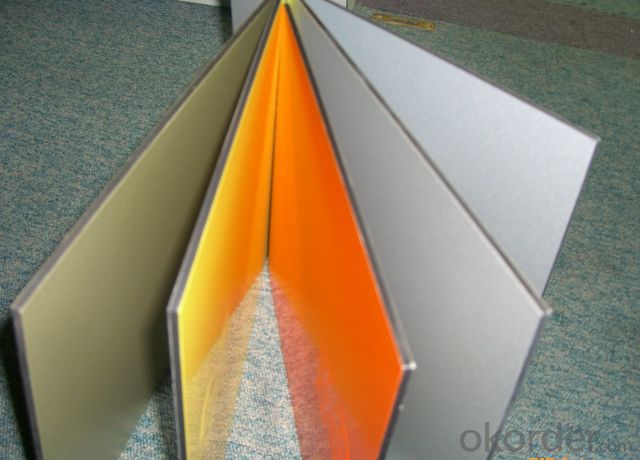

Structure of Aluminium Composite Panels PVDF Description:

PVDF coating aluminium composite panel is composed of a polyethylene core and two aluminium skins. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions, whether your project is a private home, a public building, a corporate headquarter or an office, a trading or industrial complex, or if your organisation wants to create a new image, building Corporate Design, whether for petrol stations, car showrooms, banks or supermarkets.

Main Features of Aluminium Composite Panels PVDF:

A) Light weight,flat surface and high strength

B) Excellent heat insulation ,sound insulation,fire-resistance,acid-resistance,alkali-resistance,weatherproofness and non-resonance

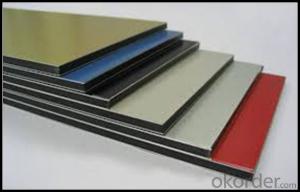

C) Various uniform colors

D) Rbright ,elegan and magnificent,fit for various designs

E) Kynar 5000 PVDF resin feature strong chemical resistance,unique colors can be easily maintained

Images of Aluminium Composite Panels PVDF:

Aluminium Composite Panels Specifications:

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Composite Panels

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- According to the content of alloy elements, aluminum plate can be divided into 8 series, namely 1***, 2***, 3***, 4***.5***.6***.7***.8***It can be divided into cold rolling and hot rolling according to different processing technologyAccording to the thickness difference can be divided into thin plate and medium plate,.GB/T3880-2006 standard in the thickness of 0.2 mm, called aluminum foilMore commonly used brands:Pure aluminum foil strip plate. 1060.. tensile plate, tube. Extrusion tube. Type. Great. Cold processing bar mainly for corrosion resistance in forming of high places, but not of high strength components, such as chemical equipment, marine equipment, railway tanker, conductive materials, instruments and meters the electrode material, and so on.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly or sustainable buildings?

- <p>Yes, aluminum sheets can be used for green building projects. They are lightweight, strong, and durable, which reduces the amount of material needed and the energy consumed in transportation. Aluminum is also 100% recyclable, meaning it can be repurposed without losing quality, reducing waste and the need for new raw materials. Additionally, aluminum has a high reflectivity, which can help in reducing heat absorption and thus lowering cooling costs in buildings. These properties make aluminum a sustainable choice for green building initiatives.</p>

- Q: Is it possible to use aluminum sheets in environments with low temperatures?

- <p>Yes, aluminum sheets can be used in cold climates. Aluminum has excellent corrosion resistance and maintains its strength in low temperatures, making it suitable for use in cold environments. It does not rust or corrode easily, which is beneficial in harsh weather conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper installation and design considerations are necessary to account for these properties in cold climates.</p>

- Q: Are aluminum sheets suitable for electrical transformers?

- Yes, aluminum sheets are suitable for electrical transformers. Aluminum is a highly conductive material that offers several advantages for use in transformers. Firstly, it has a lower electrical resistance compared to other materials like copper, which means it can efficiently transfer electrical energy. This results in lower energy losses and better overall performance. Additionally, aluminum is lightweight, making it easier to handle and install. It is also more cost-effective than copper, making it a preferred choice for large-scale transformer applications. Overall, aluminum sheets provide a reliable and efficient solution for electrical transformers.

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Aluminum sheets have the capability to be utilized in pharmaceutical lab equipment. Aluminum, a versatile material, offers numerous benefits for pharmaceutical applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity make it an excellent option for constructing trays, shelves, and cabinets that are employed for storing and transporting pharmaceutical substances. Moreover, aluminum can be easily sterilized and cleaned, which is vital for maintaining hygienic conditions in pharmaceutical laboratories. Nevertheless, it is crucial to acknowledge that specific pharmaceutical procedures may demand materials that comply with particular regulatory standards. Thus, it is always wise to seek advice from industry experts or regulatory bodies to ensure that the selected aluminum sheets fulfill the necessary requirements for their intended usage in pharmaceutical lab equipment.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry due to their lightweight, high strength, and corrosion resistance properties. They are used in the construction of aircraft structures, such as fuselages, wings, and interior components, to ensure optimal performance and fuel efficiency.

- Q: Can aluminum sheets be used for packaging?

- Aluminum sheets have the ability to be utilized for packaging purposes. The packaging industry highly values aluminum due to its numerous advantageous properties, as it is a versatile and extensively used material. The lightweight nature, strength, durability, and resistance to corrosion of aluminum make it an optimal choice for packaging applications. By using aluminum sheets, it is effortless to mold them into various shapes and sizes, offering the advantage of design flexibility and customization. In addition, aluminum possesses impermeability to light, moisture, gases, and microorganisms, guaranteeing the safety and preservation of the packaged goods. Its exceptional heat conductivity also allows for efficient heat transfer during processes like sterilization or pasteurization. Moreover, aluminum is environmentally friendly as it can be recycled, making it a sustainable option for packaging. All in all, aluminum sheets are a remarkable choice for packaging purposes due to their exceptional properties and versatility.

- Q: Are aluminum sheets suitable for architectural louvers?

- Yes, aluminum sheets are suitable for architectural louvers. Aluminum is a popular choice for louvers due to its lightweight, durable, and corrosion-resistant properties. It can be easily molded into various shapes and sizes, making it ideal for architectural applications. Additionally, aluminum louvers offer excellent strength-to-weight ratio and can withstand harsh weather conditions, making them a reliable choice for architectural projects.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- A combo of both is nice. But if I had the choice, I would go stiffer frame (aluminum) with carbon stays. For a carbon frame, the carbon has to be decent quality, not like the carbon that is used for making Raleigh frames. Low quality!

- Q: What is the maximum size available for aluminum sheets?

- The maximum size available for aluminum sheets can vary depending on the manufacturer and supplier, but they typically range from 4 feet by 8 feet to 5 feet by 10 feet.

Send your message to us

4' X 8' Aluminum Sheets for Sale - PVDF-Coated Aluminium Composite Panels - Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords