Sheet Metal Sheets 4X8

Sheet Metal Sheets 4X8 Related Searches

4X8 Metal Sheets Sheet Metal 4X8 Stainless Steel Sheets 4x8 Plastic Sheets 4X8 Galvanized Sheet Metal 4X8 Stainless Steel 4x8 Sheets Hard Plastic Sheets 4X8 4X8 Galvanized Sheet Metal 4x8 Stainless Steel Sheet Stainless Steel 4x8 Sheet Plexiglass Sheets 4X8 Polypropylene Sheets 4X8 4X8 Tin Sheets Clear Plastic Sheets 4X8 4x8 Sheet Of Stainless Steel 4X8 Sheet Aluminum 22 Gauge Sheet Metal 4X8 Galvanized Steel Sheet 4x8 4 X 8 Sheet Of Stainless Steel 4 X 8 Tin Sheets Diamond Plate Aluminum Sheets 4X8 4 By 8 Plastic Sheets 4X8 Styrofoam Sheets Aluminum Diamond Plate 4x8 Sheet 4x8 Stainless Steel Sheet Price 4x8 Sheet Diamond Plate Aluminum Aluminum Tread Plate Sheet 4x8 4 X 8 Styrofoam Sheets 1 8 Stainless Steel Sheet 4x8 Sheet Aluminum Diamond PlateSheet Metal Sheets 4X8 Supplier & Manufacturer from China

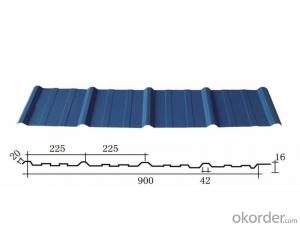

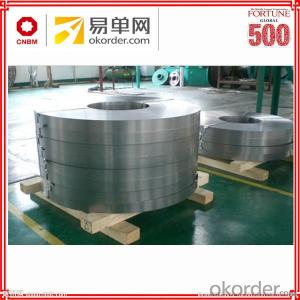

Sheet Metal Sheets 4X8 are versatile metal panels that come in a standard size of 4 feet by 8 feet, offering a wide range of applications in various industries. These sheets are commonly used in construction, automotive, and manufacturing sectors due to their durability and ease of fabrication. They can be cut, bent, and shaped to meet specific project requirements, making them an ideal choice for creating custom parts and structures. Sheet Metal Sheets 4X8 are also popular for their ability to withstand harsh weather conditions and resist corrosion, ensuring long-lasting performance in both indoor and outdoor environments.Sheet Metal Sheets 4X8 are widely used in applications such as roofing, siding, ductwork, and custom fabrication projects. They are available in various materials, including aluminum, steel, and stainless steel, catering to different needs and preferences. The sheets can be used for both functional and decorative purposes, such as creating custom enclosures, brackets, and trims, or for creating aesthetically pleasing designs in architectural projects. Their versatility and adaptability make them a popular choice among professionals and DIY enthusiasts alike.

Okorder.com is a leading wholesale supplier of Sheet Metal Sheets 4X8, offering a comprehensive inventory to cater to the diverse needs of customers. With a vast selection of materials, thicknesses, and finishes, Okorder.com ensures that customers can find the perfect sheet metal for their specific requirements. As a reliable supplier, Okorder.com is committed to providing high-quality products at competitive prices, ensuring that customers receive the best value for their investment. By partnering with Okorder.com, customers can benefit from their expertise and extensive inventory, making it easier to source the right Sheet Metal Sheets 4X8 for their projects.

Hot Products