Cold rolled steel sheet prices of construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

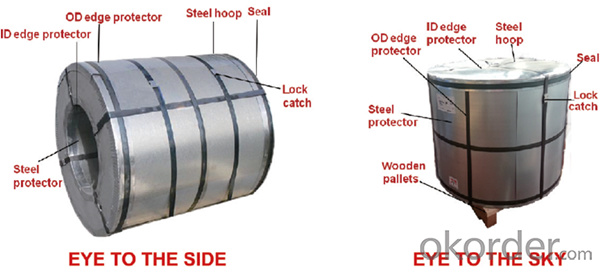

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Can steel sheets be used for industrial shelving?

- Yes, steel sheets can be used for industrial shelving. Steel is a strong and durable material that can support heavy loads, making it ideal for creating sturdy shelving units in industrial settings. Steel sheets can be easily fabricated into shelves of various sizes and shapes to meet specific storage requirements.

- Q: Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel offers excellent strength and durability, making it a reliable choice for construction projects. It can withstand harsh weather conditions and provide a secure barrier against external elements. Additionally, steel sheets can be easily manipulated to create various architectural designs, allowing for flexibility and creativity in building envelope and curtain wall designs.

- Q: How are steel sheets tested for quality and performance?

- Steel sheets are tested for quality and performance through a series of rigorous tests, such as tensile strength testing, hardness testing, dimensional accuracy inspection, surface finish examination, and corrosion resistance evaluation. These tests ensure that the steel sheets meet the required standards, specifications, and performance expectations, ensuring their durability and suitability for various applications.

- Q: Can steel sheets be used for industrial machinery?

- Yes, steel sheets can be used for industrial machinery. Steel is a versatile and durable material that is commonly used in the manufacturing of various types of industrial machinery due to its strength, resistance to corrosion, and ability to withstand high temperatures and heavy loads. Steel sheets can be easily fabricated and shaped to meet specific requirements, making them suitable for a wide range of industrial applications.

- Q: Can the steel sheets be used for kitchen countertops?

- Yes, steel sheets can be used for kitchen countertops.

- Q: Can steel sheets be used in medical applications?

- Yes, steel sheets can be used in medical applications. They are commonly used in the manufacturing of medical instruments, surgical equipment, and medical furniture due to their strength, durability, and corrosion resistance properties.

- Q: Are steel sheets suitable for manufacturing water pipes?

- Yes, steel sheets are suitable for manufacturing water pipes. Steel is a durable and strong material that can withstand high pressure and corrosion, making it an ideal choice for water pipes. Steel sheets can be easily formed and welded together to create seamless pipes that are resistant to leaks. Additionally, steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option for water pipe manufacturing.

- Q: What material can be replaced by 345D steel plate?

- Higher than its level of material of steel plate can replace.Q345D. yield in more than 345 of the steel.D class -20 degree of shock. Can replace the Q370D.Q390D.Q420D.Q460D.Q550D.Q690D., generally in engineering machinery can be higher generation low.Steel plate is made of molten steel, cooled and compressed into flat steel. The steel plate is flat, rectangular, and can be rolled directly or cut from a wide strip of steel. Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.

- Q: How are steel sheets protected during storage and handling?

- To safeguard steel sheets and guarantee their quality, a range of methods are employed during storage and handling. A frequently utilized technique involves applying a protective coating or oil to shield the sheets from moisture and other environmental factors that may lead to corrosion or rust. To shield steel sheets from direct sunlight, rain, and adverse weather conditions, they are frequently stored in covered warehouses or designated storage areas. This precautionary measure prevents any potential harm to the sheets and preserves their structural integrity. For transportation and handling, cranes or forklifts equipped with suitable lifting apparatus are commonly used to lift the steel sheets, minimizing the risk of bending or twisting. Moreover, the sheets are meticulously secured and stacked in a manner that reduces the likelihood of damage or deformation. Furthermore, steel sheets are often packaged with materials like plastic or cardboard to provide additional protection against scratches and physical harm. They may also be wrapped or sealed to prevent contact with moisture or contaminants. Overall, the objective is to maintain the quality of steel sheets and prevent any potential damage that could compromise their performance in future applications by ensuring they are stored and handled in a secure and controlled environment.

- Q: What is the difference between a galvanized and painted steel sheet?

- Galvanized steel sheets have a zinc coating that shields them from corrosion, while painted steel sheets have a layer of paint for both visual appeal and added protection against corrosion. Galvanization involves immersing the steel sheet in molten zinc, which forms a bond with the steel. This zinc coating acts as a sacrificial anode, corroding instead of the steel when exposed to elements like moisture and oxygen. As a result, galvanized steel sheets have exceptional corrosion resistance and can withstand outdoor environments for a long time. On the other hand, painted steel sheets have a layer of paint that acts as a barrier between the steel surface and the surroundings. This prevents direct contact between the steel and corrosive substances, like moisture. Consequently, the lifespan of the steel sheet is extended, and its appearance is preserved. In terms of appearance, galvanized steel sheets have a silver-gray color due to the zinc coating, while painted steel sheets can be found in various colors depending on the paint used. Galvanized steel sheets also have a textured surface because of the zinc coating, while painted steel sheets can have a smoother or textured finish based on the application technique. Ultimately, the primary difference between galvanized and painted steel sheets lies in their corrosion protection methods. Galvanized steel relies on the sacrificial corrosion of zinc, while painted steel depends on the paint's barrier effect. The choice between the two depends on factors such as the specific application, aesthetic requirements, and the desired level of corrosion resistance.

Send your message to us

Cold rolled steel sheet prices of construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords