300 Series Grade and JIS,AISI Standard stainless Steel per ton ISO certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: 201,304,310S,316L,410,430,403

Thickness: 0.4-5mm

- Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Special Use: High-strength Steel Plate

Width: 1500-2500mm

quality: high quality

price: low price

Packaging & Delivery

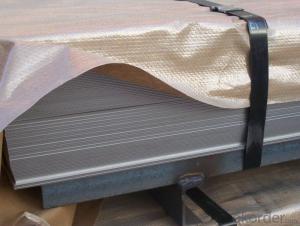

| Packaging Details: | Iron sheet packing or as clients' requirement |

|---|---|

| Delivery Detail: | within 10-30 working days |

Specifications

material quality:201,304,310S,316L,410,430,403

specification:0.4-5.0*1000/1219*1500

high quanlity and Competitive price

Stainless Steel Plate/Sheet/Coil

201,202,304,316,304L,316L,309S,310S,321,410,420,430,403

Introduction

stainless steel is one of Austenitic stainless steel. As a versatile steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Meanwhile, it is quite good in pressing, bending and other thermal processing.

Standard

The chemical and mechanical composition of the material is in accordance with GB,JIS,ASTM,and EN.

200,300,400series,201,202,301,304,304L,309S,310S,316,316L,410,430,etc.

Specification:

Our coils are directly ordered from mills.300 series stainless steel(304,304L,316L,321),duplex(2205),heat resistant steel(309s,310s)are the main product.Thickness from 0.2mm to 20mm,width is from 300mm to 2000mm,weight is from 2 tons to 26 tons.

Technology

cold draw, hot rolled, cutting, split, polished, protect coating as customer requirement

Packing

Iron sheet packing or as clients' requirement

Quality

MTC,ISO ,BV ,SGS CERTIFICATE

Application:

Machinemade industry, chemical industry, shipping industry architecture, food industry,household products,and so on.

chemical properties--stainless steel coil

| Typical chemical composition | ||||

| % | 304 | 304L | 310s | 321 |

| C | 0-0.07 | 0-0.03 | 0.8 | 0.08 |

| Mn | 0-2.0 | 0-2.0 | 2.00 | 2.00 |

| Si | 0-1 | 0-1 | 1.00 | 1.00 |

| P | 0-0.05 | 0-0.05 | 0.035 | 0.035 |

| S | 0-0.02 | 0-0.02 | 0.030 | 0.03 |

| Cr | 17.5-19.5 | 17.5-19.5 | 24.0-26.0 | 17.0-19.0 |

| Ni | 8-10.5 | 8-10.5 | 19.0-22.0 | 9.0-12.0 |

| Mo | ||||

| TI | 5×C% | |||

- Q: Are steel sheets suitable for high-vibration environments?

- Steel sheets are generally suitable for high-vibration environments due to their inherent strength and durability. Steel is known for its excellent mechanical properties, including high tensile strength and resistance to fatigue. These qualities make steel sheets capable of withstanding vibrations without significant deformation or failure. Moreover, steel sheets have the ability to dampen vibrations due to their mass and stiffness. This makes them effective in reducing the transmission of vibrations to other components or structures. Steel sheets can absorb and dissipate the energy generated by vibrations, minimizing the potential for damage or disruption. Additionally, steel sheets can be designed and manufactured to meet specific requirements for high-vibration environments. They can be reinforced or treated with coatings to enhance their resistance to corrosion, wear, and fatigue, further improving their suitability for such conditions. However, it is essential to consider the specific characteristics and intensity of the vibration environment when determining the suitability of steel sheets. Factors such as frequency, amplitude, and duration of vibrations should be taken into account. In some extreme cases, alternative materials or specialized designs may be necessary to ensure optimal performance and longevity. In conclusion, steel sheets are generally suitable for high-vibration environments due to their strength, durability, and ability to dampen vibrations. However, a thorough evaluation of the specific conditions is crucial to determine the most appropriate solution for each application.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets are known for their exceptional strength and durability, which makes them highly resistant to impact and damage. Due to their high tensile strength, steel sheets can withstand heavy loads and resist deformation or breakage when subjected to external forces. They are often used in applications where impact resistance is critical, such as in construction, automotive manufacturing, and industrial settings. Additionally, steel sheets can withstand extreme temperatures, corrosion, and environmental factors, which further contributes to their overall resistance to damage. However, it is important to note that the specific resistance to impact or damage may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: Are steel sheets magnetic?

- Yes, steel sheets are magnetic.

- Q: Can steel sheets be used for toolboxes and cabinets?

- Yes, steel sheets can be used for toolboxes and cabinets. Steel is a durable and strong material, making it suitable for creating sturdy toolboxes and cabinets that can withstand heavy use and provide ample storage space.

- Q: Who knows the wire width of the steel mesh?

- Steel net is diamond, respectively from the left and right (up or down) with two curved metal strips, the two metal strips are generally not the same thickness, the thickness is the stem width, the width is less than the thickness of material.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are renowned for their outstanding ability to resist chemical exposure. They exhibit a high level of resistance to corrosion and can endure exposure to a wide array of chemicals, including acids, alkalis, solvents, and other substances that cause corrosion. This exceptional resistance is primarily attributed to the formation of a protective oxide layer, known as patina, on the surface of the steel. This layer acts as a barrier, preventing the chemicals from attacking the steel. Moreover, steel sheets can be further safeguarded by applying various protective coatings, such as galvanization, epoxy coatings, or powder coatings. These coatings provide an extra layer of protection and enhance the steel's resistance to chemical exposure. However, it is important to acknowledge that the resistance of steel sheets to chemical exposure may vary based on the specific type and concentration of the chemicals involved. Highly concentrated or aggressive chemicals may still lead to some degree of corrosion or damage to the steel surface over time. Hence, it is crucial to carefully consider the specific chemical environment and select the appropriate grade of steel and protective coating to ensure optimum resistance to chemical exposure. In summary, steel sheets are a dependable and durable choice for applications that demand resistance to chemical exposure. With careful selection and maintenance, they can effectively withstand diverse chemical environments and deliver long-lasting performance.

- Q: How do steel sheets perform in seismic zones?

- Steel sheets perform well in seismic zones due to their high tensile strength and ductility. They have the ability to absorb and redistribute energy during seismic events, reducing the risk of structural failure. Additionally, steel structures can be designed to be flexible and resistant to lateral forces, making them a preferred choice for buildings in areas prone to earthquakes.

- Q: What is the difference between an open plate and an original plate?

- From the point of view of two kinds of steel material without distinction, general specification of thin strip, narrow width, tolerance requirements are high, but the strip roughness was poor single open flat rolled steel plate. And it is exactly the same as the original flat material, but because the plate is after uncoiling, leveling, shear processed steel belt, the comprehensive mechanical performance is not as good as the original flat, so some important occasions the use of the original plate, should pay attention to in the procurement

- Q: Are steel sheets resistant to termite infestation?

- No, steel sheets are not resistant to termite infestation. Termites are known to feed on wood and other cellulose-based materials, but they can also cause damage to steel structures indirectly. Termites can burrow through other materials, such as concrete or insulation, to reach the wooden components of a structure. Therefore, while steel sheets themselves may not be directly affected by termites, the overall integrity of a building or structure can still be compromised if termites gain access to the wooden components. It is important to take preventive measures and regularly inspect and treat any vulnerable areas to protect against termite infestation, regardless of the presence of steel sheets.

- Q: What are the disadvantages of using steel sheets?

- One of the main disadvantages of using steel sheets is their susceptibility to corrosion. Steel is prone to rusting when exposed to moisture or certain chemicals, which can compromise its structural integrity over time. Additionally, steel sheets are relatively heavy and can be challenging to handle and transport compared to other materials. Moreover, steel sheets require proper insulation to prevent condensation and thermal bridging issues. Lastly, steel sheets are subject to price volatility as the cost of steel can fluctuate significantly in response to market conditions.

Send your message to us

300 Series Grade and JIS,AISI Standard stainless Steel per ton ISO certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords