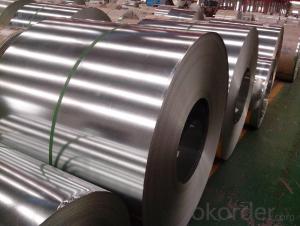

Galvanized Iron Sheet, GI Sheet, Galvanized Sheet Metal Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

During our home decoration, many people prefer to use bright shiny stainless steel sheet as some parts of the decorative material. However, a wide range of stainless steel sheet, many friends are not very clear about the differences between them, and then, how to classify the Stainless steel sheet?

Production material of stainless steel plate is stainless steel; stainless steel has corrosion-resistant, high temperature characteristics, which makes it very popular with by the majority of consumers in the market. However, plate type on the market variety; here we will introduce two common classification of stainless steel sheet.

According to the manufacturing process

Stainless steel sheet made according to the method can be divided into cold-rolled sheet and hot-rolled sheet.

Hot-rolled stainless steel sheet is heated to high temperatures after the iron billet, then rolling roughing and finishing of steel sheet formation. After hot-rolled stainless steel sheet has good toughness, good stretchability. However, hot-rolled stainless steel sheet has a huge drawback is made of stainless steel sheet hardness is not very high; the texture is not very hard.

- Q: What can be painted on galvanized steel sheet?

- Paint matching1. The paint preparation system used for galvanized steel in soaking or humid environment must be alkali resistant and can not be saponified. Therefore, it is advisable to choose epoxy type coating. Best with epoxy zinc yellow primer.2, for exposure in the dry environment of galvanized steel, zinc yellow epoxy primer can be used with acrylic polyurethane topcoat, or intermediate epoxy zinc chromate primer + epoxy micaceous iron oxide + fluorocarbon topcoat with ultra weatherability, long service life of the supporting scheme.In short, surface treatment is very important, considering the durability of galvanized parts, it is recommended to use the above two kinds of matching paint to ensure the normal service life and reduce the cost of intermediate maintenance.

- Q: What are the different types of steel sheet alloys?

- There exists a range of steel sheet alloys, each possessing distinct properties and applications. Among the most prevalent steel sheet alloys are: 1. Carbon Steel: This variety, composed primarily of iron and carbon, serves as a fundamental form of steel. Its notable strength and affordability render it extensively used in the construction, automotive, and manufacturing sectors. 2. Stainless Steel: Distinguished by its resistance to corrosion, stainless steel is produced by introducing chromium and other alloying elements to carbon steel. It finds common employment in environments where hygiene and durability hold significance, such as kitchen appliances, medical equipment, and architectural structures. 3. Galvanized Steel: To protect against corrosion, this type of steel is coated with a layer of zinc. Galvanized steel sheets find frequent application in outdoor settings, including roofing, fencing, and automotive components. 4. Alloy Steel: Alloy steel sheets are created by incorporating diverse alloying elements, like nickel, chromium, and molybdenum, into carbon steel. These alloys heighten the strength, hardness, and wear resistance of the steel, rendering it suitable for industries such as aerospace, automotive, and machinery. 5. Tool Steel: This steel variety is specifically engineered for the production of tools and dies. It distinguishes itself through high hardness, resistance to deformation, and the ability to retain sharp edges. Tool steel sheets are commonly employed in the manufacturing of cutting tools, drills, and molds. 6. Electrical Steel: This steel undergoes specialized processing to minimize magnetic losses and enhance electrical conductivity. Electrical steel sheets are utilized in the production of transformers, electric motors, and generators. These examples represent merely a fraction of the diverse steel sheet alloys accessible. Depending on the specific requirements of a project or application, engineers can opt for the appropriate alloy to achieve the desired properties and performance.

- Q: What is the price of each steel sheet?

- The price of each steel sheet may vary depending on various factors such as size, thickness, quality, and market conditions. It is best to check with steel suppliers or manufacturers to get an accurate and up-to-date price for the specific steel sheet you are interested in purchasing.

- Q: What are the maintenance requirements for steel sheets?

- The maintenance requirements for steel sheets typically include regular cleaning to prevent the buildup of dirt, dust, and moisture, as well as the application of rust-resistant coatings or paints to protect against corrosion. Additionally, it is important to store steel sheets in a dry and well-ventilated area to avoid moisture damage.

- Q: What are the different types of steel sheet finishes for architectural applications?

- There are several different types of steel sheet finishes that are commonly used for architectural applications. These finishes not only enhance the aesthetic appeal of the steel sheets but also provide protection against corrosion and other environmental factors. 1. Mill Finish: This is the most basic type of finish, where the steel sheet is left as it comes from the mill. It has a dull, gray appearance and is typically used for applications where aesthetics are not a priority. 2. Brushed Finish: Also known as a satin finish, this type of finish is achieved by brushing the steel sheet with a fine abrasive material. It gives a smooth, linear texture to the surface, resulting in a contemporary and elegant appearance. 3. Polished Finish: This finish is achieved by polishing the steel sheet with abrasive materials until it becomes smooth and reflective. It provides a high-gloss, mirror-like appearance, making it suitable for applications that require a sophisticated and luxurious look. 4. Embossed Finish: In this finish, the steel sheet is pressed with embossing tools to create textured patterns or designs on the surface. This gives the sheet a unique and decorative appearance, making it ideal for architectural applications where visual interest is desired. 5. Patterned Finish: This finish involves applying a pattern or texture onto the steel sheet using various techniques like etching, laser cutting, or perforating. It creates a visually appealing surface with intricate designs, making it suitable for both functional and decorative purposes. 6. Powder Coated Finish: In this finish, a layer of dry powder paint is electrostatically applied to the steel sheet and then cured under heat. It provides a durable and vibrant finish, available in a wide range of colors and textures. This finish is highly resistant to chipping, scratching, and fading, making it ideal for exterior architectural applications. 7. Galvanized Finish: This finish is achieved by applying a layer of zinc coating onto the steel sheet through a process called galvanization. It provides excellent corrosion resistance, making it suitable for outdoor architectural applications where the steel sheet is exposed to harsh environments. Overall, the choice of steel sheet finish depends on the desired aesthetics, durability, and environmental conditions of the architectural application.

- Q: What is the process of powder coating steel sheets?

- The process of powder coating steel sheets involves several steps. First, the steel sheets are thoroughly cleaned to remove any dirt, grease, or rust. Then, a fine powder coating material is electrostatically charged and sprayed onto the surface of the steel sheets. The charged particles adhere to the metal surface, creating a uniform coating. The coated sheets are then heated in an oven, allowing the powder to melt and cure, forming a durable and protective finish. Once cooled, the steel sheets are ready for further processing or use.

- Q: What is the weight of a steel sheet?

- The weight of a steel sheet can vary depending on its dimensions, thickness, and density.

- Q: What are the different surface patterns available for steel sheets?

- Some of the different surface patterns available for steel sheets include smooth, textured, brushed, embossed, and perforated.

- Q: Are steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding. Steel cladding offers durability, strength, and versatility in design, making it a popular choice for architects. It can be easily formed into different shapes and sizes, providing flexibility in creating unique building facades. Additionally, steel cladding is resistant to weather conditions, fire, and pests, making it a long-lasting and low-maintenance option for architectural applications.

- Q: How do steel sheets handle thermal conductivity?

- Steel sheets have high thermal conductivity, which means they can efficiently transfer heat. This property allows steel sheets to quickly and evenly distribute heat across their surface, making them suitable for various applications such as heat transfer systems, cookware, and building materials.

Send your message to us

Galvanized Iron Sheet, GI Sheet, Galvanized Sheet Metal Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords