Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | steel sheet, SGCC, DX51D, Q195, Q215, Q235, Q345 | Thickness: | 0.3-115mm |

| Place of Origin: | Tianjin, China (Mainland) | Brand Name: | hot dipped galvanized steel sheet | Model Number: | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430 ect |

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Galvanized |

| Application: | truck frames, brackets, crane booms,shipbuilding industry | Special Use: | High-strength Steel Plate | Width: | 1000-2000mm |

| Length: | 2000-6000mm or as your requirements | name: | galvanized steel sheet | MOQ: | 25T |

| Certification: | ISO9001:2008 |

Packaging & Delivery

| Packaging Details: | silicon steel sheet of transformer:Standard export seaworthy package. |

| Delivery Detail: | 15-20 days after receiving your deposit or L/C |

Specification

Thickness | 0.3 mm-115mm |

Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm as customer request |

Length | 2000mm-6000mmor as customer request |

Standard | AISI, ASTM, BS, GB, DIN, JIS, etc |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc |

Surface | Coated(2B, BA, 8K, No. 4 No.1) Galvanized or bare |

Packaging | Standard export sea-worthy packing |

Technique | Hot rolled / cold rolled |

Delivery time | 10-25days |

Supply ability | 3,0000MT per month |

Payment terms | L/C, T/T, D/P |

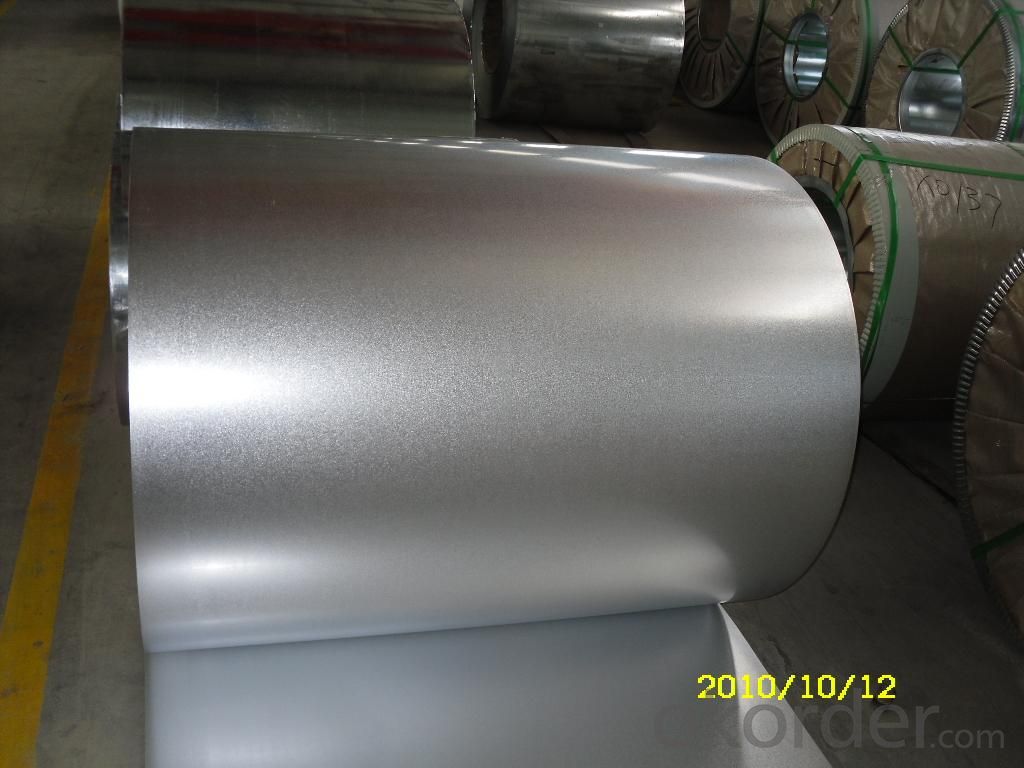

Picture

- Q: What are the load-bearing capacities of steel sheets?

- The load-bearing capacities of steel sheets vary depending on their size, thickness, and grade. Generally, steel sheets can bear significant loads due to their high strength and durability. However, it is important to consult engineering specifications or consult with a structural engineer to determine the specific load-bearing capacity of a particular steel sheet.

- Q: Are the steel sheets resistant to vibration or shock?

- Yes, steel sheets are generally resistant to vibration and shock. Steel is known for its high strength and durability, making it capable of withstanding external forces such as vibrations and shocks. The rigid nature of steel allows it to absorb and distribute the energy caused by vibrations or shocks, preventing any significant damage or deformation. Additionally, steel sheets are often used in applications where resistance to vibrations and shocks is crucial, such as in construction, automotive, and aerospace industries. However, it is important to note that the exact resistance of steel sheets to vibration or shock will depend on factors such as the thickness and quality of the steel used, as well as the specific magnitude and frequency of the vibrations or shocks.

- Q: Can steel sheets be used for insulation cladding?

- Typically, insulation cladding does not involve the use of steel sheets. Instead, materials like foam boards, mineral wool, or fiberglass are commonly chosen for their thermal insulation properties. These materials are effective in minimizing heat transfer and enhancing energy efficiency. Conversely, steel sheets are more frequently utilized for structural purposes or as a protective layer owing to their robustness and durability. Though steel sheets can offer some protection, they lack the requisite insulation properties required to effectively prevent the transfer of heat or cold. Consequently, it is advisable to employ suitable insulation materials specifically designed for cladding purposes.

- Q: 16 what is the hardness of manganese steel plates?

- 16 hardness of manganese steel plate is 45 -50HRC.

- Q: Can steel sheets be used for fire-rated doors?

- Fire-rated doors can indeed utilize steel sheets. In fact, steel is extensively employed in the creation of fire-rated doors due to its exceptional strength, longevity, and fire-resistance characteristics. Generally, steel sheets employed in fire-rated doors are crafted with multiple layers of fire-resistant substances, like gypsum or mineral core, which are placed between the steel sheets. This method of construction effectively impedes the propagation of fire and smoke, ensuring a dependable barrier in case of a fire. Furthermore, steel is renowned for its structural integrity, rendering it an appropriate option for fire-rated doors that must endure elevated temperatures and pressure.

- Q: Are steel sheets suitable for medical equipment manufacturing?

- Yes, steel sheets are commonly used in medical equipment manufacturing due to their durability, strength, and resistance to corrosion. Additionally, steel sheets can be easily sterilized, making them suitable for use in healthcare settings where cleanliness and hygiene are paramount.

- Q: How are steel sheets inspected for defects?

- Steel sheets are inspected for defects using various techniques and methods to ensure their quality and reliability. One common method is visual inspection, where trained inspectors carefully examine the surface of the steel sheet for any visible defects such as cracks, scratches, dents, or surface irregularities. This is typically done under proper lighting conditions to enhance visibility. Another technique is magnetic particle inspection, which is used to detect surface or near-surface defects in ferromagnetic materials like steel. In this method, a magnetic field is applied to the steel sheet, and iron particles are then applied to the surface. If there are any defects, these particles will be attracted and form visible indications, allowing inspectors to identify the location and size of the defect. Ultrasonic inspection is another commonly used method that involves the use of high-frequency sound waves to detect internal defects in steel sheets. Ultrasonic waves are passed through the material, and any changes in the wave patterns caused by defects are detected by sensors. This non-destructive testing method can identify defects such as voids, cracks, or inclusions that may not be visible to the naked eye. Other techniques used for defect detection in steel sheets include eddy current testing, where electrical currents are induced in the material to detect surface defects, and X-ray inspection, which uses high-energy X-rays to reveal any internal flaws. Overall, a combination of visual inspection and non-destructive testing methods is employed to thoroughly inspect steel sheets for defects, ensuring that only high-quality sheets are used in various applications like construction, automotive, or manufacturing industries.

- Q: Can the steel sheets be used for decorative purposes?

- Yes, steel sheets can be used for decorative purposes. They can be cut, shaped, and finished in various ways to create unique and visually appealing designs for applications such as architectural features, wall cladding, furniture, and artwork.

- Q: The differences and uses of cold rolling and hot rolling

- There are different reasons for the residual stress in hot rolled and cold-rolled steel sections, so the distribution of the residual stresses is also quite different. The residual cold-formed steel section stress distribution is curved, and hot rolled steel or steel welding section on the residual stress distribution is thin.

- Q: What is the process of annealing steel sheets?

- Annealing steel sheets is a heat treatment process that involves heating the steel sheets to a specific temperature and then slowly cooling them to soften the material and relieve internal stresses. This process helps improve the steel's ductility, machinability, and overall mechanical properties.

Send your message to us

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords