16 Gage Sheet Metal

16 Gage Sheet Metal Related Searches

16 Gauge Sheet Steel 16 Gauge Stainless Steel Sheet 19 Gauge Sheet Metal 16g Stainless Steel Sheet 30 Gauge Sheet Metal 18 Gauge Galvanized Sheet Metal Sheet Metal 20 Gauge 28 Gauge Galvanized Sheet Metal 22 Gauge Sheet Metal 4X8 4X8 Metal Sheets Sheet Metal 4X8 Sheet Metal Purchase 4X8 Galvanized Sheet Metal Sheet Metal Sheets 4X8 1 8 Stainless Steel Sheet Steel Mesh Sheet Galvanized Sheet Metal 4X8 1/8 Stainless Steel Sheet 4 X 8 Sheet Of Stainless Steel 4x8 Sheet Of Stainless Steel Imitation Slate Roofing Sheets 6 Mil Plastic Sheeting Thin Stainless Steel Sheets Wrought Iron Mesh Sheet 4x8 Stainless Steel Sheet Cold Rolled Steel Sheet Hot Rolled Steel Sheet 4X8 Sheet Aluminum Pu12 Sheet Pile 6 X 4 Plywood Sheets16 Gage Sheet Metal Supplier & Manufacturer from China

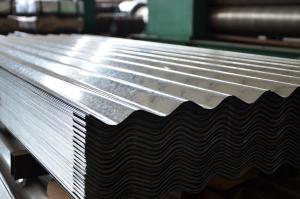

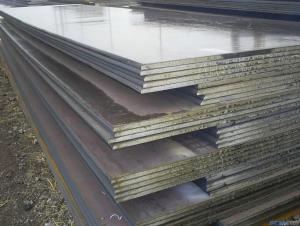

16 Gage Sheet Metal, a versatile and widely used product, consists of various types of metal sheets with a thickness of 0.060 inches. These sheets are commonly made from materials such as aluminum, steel, and stainless steel, offering a range of options to suit different applications and requirements. The 16 Gage Sheet Metal is utilized in numerous industries, including construction, automotive, and manufacturing, where it is employed in the fabrication of various components, structures, and parts. Its durability, strength, and ease of manipulation make it an ideal choice for a multitude of projects, from simple repairs to intricate designs.16 Gage Sheet Metal is extensively used in various applications, such as roofing, siding, and cladding, where its strength and resistance to corrosion provide long-lasting protection. In the automotive industry, it is employed in the manufacturing of car bodies, engine components, and exhaust systems. Additionally, it is used in the fabrication of appliances, tools, and machinery in the manufacturing sector. The product's versatility allows for easy cutting, bending, and shaping, making it a popular choice for both professional and DIY enthusiasts.

Okorder.com is a reputable wholesale supplier of 16 Gage Sheet Metal, boasting a vast inventory that caters to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 16 Gage Sheet Metal products they offer meet the highest industry standards. Their extensive stock allows customers to find the specific type of sheet metal they require, whether it be aluminum, steel, or stainless steel, and in the desired thickness and dimensions. By partnering with Okorder.com, customers can benefit from competitive prices, prompt delivery, and exceptional customer service, making it a reliable choice for their 16 Gage Sheet Metal needs.

Hot Products