Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Carbon Steel Plate SA516 Grade 60 Description:

Carbon Steel Plate SA516 Grade 60 is an ideal steel for use in moderate to lower working temperatures. Carbon Steel Plate SA516 Grade 60 is used in the fabrication of weldable industrial boilers and steel pressure vessels. It is a normalized steel which is known for its excellent notch toughness and weldability and is primarily found in pressurised service throughout the oil, gas and petrochemical industry.

2、Main Features of the Carbon Steel Plate SA516 Grade 60:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3、Hot Rolled Carbon Steel Plate Images:

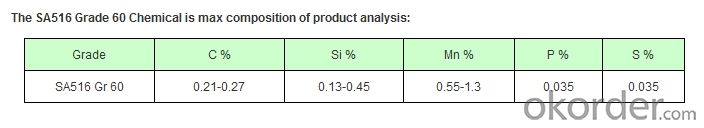

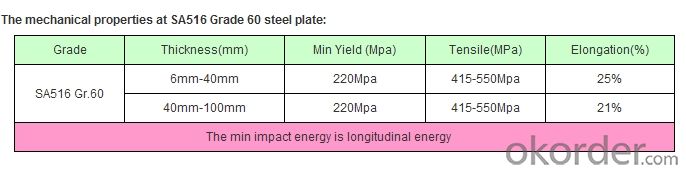

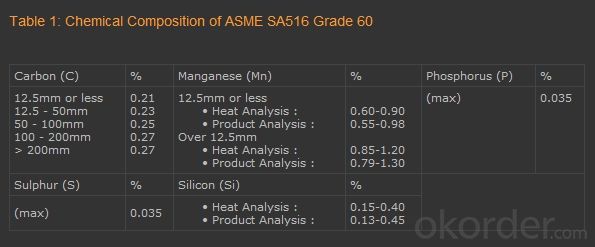

4、Carbon Steel Plate SA516 Grade 60 Specification:

| Grade: | S235jr S275jr S355jrSS400 Q235 Q345 ASTM A36 |

| Thickness: | 1.8-100mm |

| Width: | 1000-2500mm |

| Length: | 2000-12000mm as request |

| Mill: | qualified steel mill in China |

| Bundle weight: | max 4mt or as request |

| Package: | seaworthy packing ( bared with steel strips) |

5、FAQ of Hot Rolled Carbon Steel Plate:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.

③ How can we get more information?

You can contact us by Email or call us directly and we will do our best to give you valuable information as much as possible but this service is not available on weekends.

- Q: Can steel sheets be used for making shipping containers?

- Yes, steel sheets can be used for making shipping containers. In fact, steel is the most commonly used material for constructing shipping containers due to its strength, durability, and resistance to various weather conditions and environmental factors. Steel sheets are typically cut, bent, and welded together to form the walls, roof, and floor of the container. This construction method ensures that the shipping container is sturdy and capable of withstanding the rigors of transportation, including stacking, lifting, and exposure to harsh marine environments. Additionally, steel containers are easily customizable and can be modified to meet specific requirements for cargo storage and transportation.

- Q: What are the different thickness tolerances for steel sheets?

- The thickness tolerances for steel sheets can vary depending on the specific grade and type of steel being used. However, common thickness tolerances for steel sheets typically range from +/- 0.001 inches to +/- 0.030 inches, with tighter tolerances typically being required for more precise applications.

- Q: Can steel sheets be used for signage or advertising purposes?

- Yes, steel sheets can be used for signage or advertising purposes. They are durable, weather-resistant, and can be easily customized with various design options. Steel sheets are commonly used for outdoor signs, billboards, and other advertising displays due to their strength and long-lasting quality.

- Q: How do steel sheets perform in high-pressure applications?

- Steel sheets perform well in high-pressure applications due to their high strength and durability. They can withstand the intense pressure without deforming or breaking, making them suitable for various industries such as oil and gas, aerospace, and automotive. Additionally, steel sheets have excellent resistance to corrosion and temperature fluctuations, further enhancing their performance in high-pressure environments.

- Q: Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions due to their inherent strength, durability, and resistance to corrosion. They can withstand heavy rain, snow, high winds, and even hailstorms without getting damaged. Additionally, steel sheets are also fire-resistant, making them a reliable choice for various applications in extreme weather environments.

- Q: Can steel sheets be powder coated?

- Yes, steel sheets can be powder coated. Powder coating is a popular method used to provide a durable and attractive finish on steel surfaces.

- Q: What is the difference between a galvanized and painted steel sheet?

- A galvanized steel sheet is one that has been coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, involves immersing the steel sheet in a bath of molten zinc, which forms a bond with the underlying steel. This zinc coating acts as a sacrificial anode, meaning that it corrodes instead of the steel when exposed to elements such as moisture and oxygen. As a result, galvanized steel sheets have excellent corrosion resistance and can last for a long time in outdoor environments. On the other hand, a painted steel sheet is one that has been coated with a layer of paint to provide both aesthetic appeal and additional protection against corrosion. The paint acts as a barrier between the steel surface and the surrounding environment, preventing moisture and other corrosive substances from coming into direct contact with the steel. This helps to prolong the lifespan of the steel sheet and maintain its appearance. In terms of appearance, galvanized steel sheets have a characteristic silver-gray color due to the zinc coating, while painted steel sheets can come in a wide range of colors depending on the type of paint used. Galvanized steel sheets also have a textured surface due to the presence of the zinc coating, while painted steel sheets can have a smoother or textured finish depending on the application technique. Ultimately, the main difference between galvanized and painted steel sheets lies in the method of protection against corrosion. Galvanized steel relies on the sacrificial corrosion of zinc, while painted steel relies on the barrier effect of the paint. The choice between the two depends on factors such as the specific application, aesthetic requirements, and the level of corrosion resistance needed.

- Q: What is the average lifespan of steel sheets?

- The average lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, on average, steel sheets can last anywhere from 20 to 30 years or even longer with proper care and maintenance.

- Q: What are the different sheet metal cutting techniques for steel sheets?

- Steel sheets can be cut using various techniques, specifically designed for this purpose. Here are some commonly employed methods: 1. Shearing: By applying a high force, a shear or a pair of blades is used to cut the steel sheet. This method is ideal for straight cuts and works with both thin and thick steel sheets. 2. Laser cutting: A high-powered laser beam is employed to slice through the steel sheet. This technique offers high precision and allows for intricate designs. It is suitable for thin and thick steel sheets. 3. Plasma cutting: Here, a plasma torch generates an electrically conductive jet of plasma to cut through the steel. This method is commonly used for thick steel sheets and provides fast cutting speeds. 4. Waterjet cutting: The steel sheet is cut using a high-pressure jet of water mixed with abrasive particles. Waterjet cutting is versatile and can handle different thicknesses of steel sheets. It is also suitable for cutting heat-sensitive materials. 5. Punching: A punch and die set are used to create holes or various shapes in the steel sheet. Punching is a cost-effective method for repetitive cuts and can be used with thin and thick steel sheets. 6. Abrasive cutting: Thin steel sheets can be ground through using an abrasive wheel or disc. This technique provides a smooth finish. Factors such as the steel sheet's thickness, required precision, design complexity, and material heat sensitivity determine the choice of cutting technique. Each method has its own advantages and limitations, so it is crucial to take these factors into account when selecting the appropriate method for cutting steel sheets.

- Q: What is the cost of a standard steel sheet?

- The cost of a standard steel sheet can vary depending on factors such as size, thickness, and quality, as well as market conditions. It is best to check with suppliers or consult current market prices for an accurate cost estimate.

Send your message to us

Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords