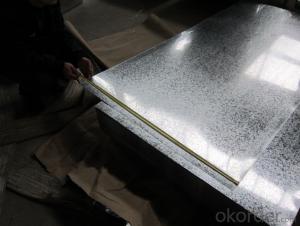

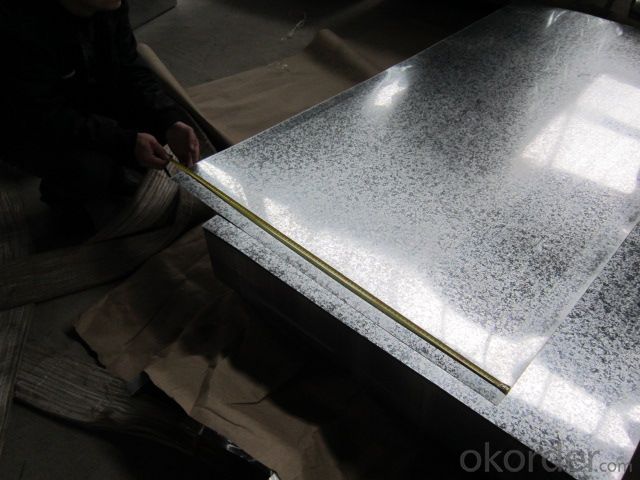

Hot-dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dipped Galvanized Steel Sheet in Sheet

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Superiority:

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

What is it Colored aluminum door? Have you seen it? Very much the type of door, sliding doors, folding doors, swing doors, etc., what type do you prefer? What classification Colored aluminum door?

Colored aluminum is the recent rise in the field of doors and windows, a new profile. In fact, almost Colored aluminum and aluminum, but the thickness Colored aluminum thick aluminum than the previous lot, and we had powder coating or electrophoresis. Colored aluminum alloy surface treatment of aluminum alloy performance is very stable and difficult to corrosion, usually surface after special treatment can be guaranteed for at least 30 years without fading LK.

Prospects of Colored aluminum

Surface oxidation-treated Colored aluminum display in the supermarket is very eye-catching. The above not only printed Logo, but also a perfect display of the characteristics of the product sold. Colored aluminum not only promote product sales, but also highlights the corporate image, use the display Colored aluminum is Value for money.

Colored aluminum door Category

1. Sliding doors: the appearance design is exquisite and elegant, exquisite and meticulous workmanship, surface profiles a variety of colors, and high intensity does not change color. Raster buckle through various styles and combinations of glass can be processed dozens of beautifully shaped door.

2. Hanging doors: In addition to having the characteristics of sliding doors, there is no threshold under the door inside and outside the ground into one, convenient for the elderly and children.

3. Folding: In addition to having a sliding door features, the door has a beautiful and sophisticated, open space is larger and so on.

4. Closet doors: In addition to having a sliding door features, compact design arc shape, thick wall sections, through a combination of different styles of doors and bar, can form a variety of styles closet doors.

5. Folding partition: The product is made of high quality accessories pulley folding, sliding folding lithe, while retaining the sliding door elegant appearance, easy to push, but its folding doors can push against both sides of the open space is larger. It is suitable for balconies and kitchens, etc. partition.

6. Cailv insulation were flat open: The window profiles are made of an insulating strip connecting the two sections together, using hollow glass, which is characterized by good sealing performance and energy saving, suitable for housing outside doors and windows can be used inside and outside of different colors aluminum, is currently building outside the window type commonly used.

- Q: Are steel sheets suitable for oil and gas industry applications?

- Yes, steel sheets are suitable for oil and gas industry applications. Steel has excellent strength and durability properties, making it ideal for withstanding the harsh conditions and high pressures found in the oil and gas industry. Additionally, steel sheets can be coated or treated to enhance their resistance to corrosion, further increasing their suitability for oil and gas applications.

- Q: How are steel sheets inspected for defects?

- To ensure the quality and reliability of steel sheets, various techniques and methods are utilized for defect inspection. One such method involves trained inspectors conducting visual inspections, carefully examining the surface of the steel sheet for visible defects such as cracks, scratches, dents, or irregularities. This examination takes place under appropriate lighting conditions to optimize visibility. Another technique employed is magnetic particle inspection, primarily used for detecting surface or near-surface defects in ferromagnetic materials like steel. By applying a magnetic field to the steel sheet and subsequently introducing iron particles onto the surface, any defects present will attract these particles, forming visible indications. This allows inspectors to pinpoint the location and size of the defect. Ultrasonic inspection, on the other hand, utilizes high-frequency sound waves to identify internal defects within steel sheets. By passing ultrasonic waves through the material and utilizing sensors to detect any alterations in wave patterns caused by defects, this non-destructive testing method can identify imperfections such as voids, cracks, or inclusions that may not be discernible to the naked eye. Additional techniques employed for defect detection in steel sheets include eddy current testing, where electrical currents are induced in the material to identify surface defects, and X-ray inspection, which employs high-energy X-rays to reveal any internal flaws. In summary, a combination of visual inspection and non-destructive testing methods is utilized to conduct thorough defect inspections on steel sheets. This ensures that only high-quality sheets are utilized in various industries, including construction, automotive, and manufacturing.

- Q: Can steel sheets withstand extreme temperatures?

- Yes, steel sheets can withstand extreme temperatures. Steel has a high melting point and is known for its excellent heat resistance, making it suitable for use in various industries that require materials to endure extreme temperatures.

- Q: Are steel sheets suitable for railway infrastructure?

- Yes, steel sheets are suitable for railway infrastructure. Steel is a widely used material in the construction of railway infrastructure due to its strength, durability, and versatility. One of the main advantages of using steel sheets for railway infrastructure is their high strength-to-weight ratio. Steel is known for its exceptional strength, allowing it to withstand heavy loads and provide long-lasting support to railway tracks, bridges, and other structures. This strength is crucial in ensuring the safety and stability of the railway system, especially when dealing with the immense weight and impact forces exerted by trains. Additionally, steel sheets offer excellent durability and resistance to wear and tear. Railway infrastructure is subjected to constant stress, including vibrations, impacts, and extreme weather conditions. Steel's inherent properties make it highly resilient to these factors, minimizing the need for frequent repairs and maintenance. This durability translates into significant cost savings in the long run, as steel structures have a longer lifespan compared to other materials. Moreover, steel sheets are highly versatile and can be easily fabricated into various shapes and sizes to meet specific railway infrastructure requirements. This flexibility allows for the efficient construction of rails, sleepers, bridges, and other components needed for a functional and safe railway system. Steel's adaptability also enables easy modifications and expansions to the infrastructure as needed, ensuring compatibility with evolving transportation needs. In conclusion, steel sheets are well-suited for railway infrastructure due to their strength, durability, and versatility. Their high strength-to-weight ratio, resistance to wear and tear, and ease of fabrication make them an ideal choice for constructing and maintaining railway tracks, bridges, and other structures. The use of steel in railway infrastructure ensures the safety, efficiency, and longevity of the railway system.

- Q: What are the different hardness levels available for steel sheets?

- The different hardness levels available for steel sheets typically range from soft (low hardness) to hard (high hardness). Some common hardness scales used for steel sheets include Rockwell, Brinell, and Vickers. These scales provide different ways to measure and express the hardness of steel, allowing users to choose the appropriate level based on their specific needs and applications.

- Q: Are steel sheets resistant to radiation?

- Yes, steel sheets are generally resistant to radiation. Steel has high density and atomic number, which enables it to absorb and scatter radiation effectively. This property makes steel sheets commonly used in industries where radiation shielding is required, such as nuclear power plants and medical facilities.

- Q: What is the weight of each steel sheet?

- The weight of each steel sheet depends on its dimensions and thickness, as steel comes in various sizes and densities.

- Q: How do steel sheets perform in fire-rated applications?

- Steel sheets perform well in fire-rated applications due to their high melting point and excellent structural integrity. When exposed to fire, steel sheets maintain their strength and stability, making them a reliable choice for fire-resistant construction. Moreover, steel sheets do not contribute to the spread of fire or the release of toxic fumes, enhancing the safety of occupants during a fire incident. Additionally, steel sheets offer excellent thermal insulation, helping to prevent the transfer of heat from the fire to other areas of the building. This property allows for the containment of fires and limits the damage caused. Overall, the use of steel sheets in fire-rated applications provides a robust and effective solution for fire protection in buildings.

- Q: What is the average wind load capacity of steel sheets?

- The wind load capacity of steel sheets can differ depending on a range of factors, including sheet thickness, steel type, and the specific design and installation of the structure. However, steel sheets are renowned for their robustness and endurance, enabling them to withstand substantial wind loads. When it comes to roofing or cladding applications, steel sheets are typically engineered to meet precise wind load demands in accordance with regional building codes and standards. These standards take into consideration factors such as geographical location, building height, exposure category, and wind speed. Engineers and architects rely on calculations and simulations to determine the wind load capacity of steel sheets and analyze the forces exerted by the wind on the structure. They take various factors into account, including wind pressure, building orientation, surface area, and the shape and profile of the steel sheets. In conclusion, the average wind load capacity of steel sheets cannot be generalized due to the influence of numerous factors. It is essential to seek guidance from a structural engineer or building professional to establish the appropriate wind load capacity requirements for a specific steel sheet application.

- Q: How do steel sheets perform in extreme weather conditions?

- Steel sheets are highly durable and resistant to extreme weather conditions. They are able to withstand high winds, heavy rain, snow, and even hail. Due to their strength and corrosion-resistant properties, steel sheets provide excellent protection against harsh weather elements, making them a reliable choice for various applications in extreme weather conditions.

Send your message to us

Hot-dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords