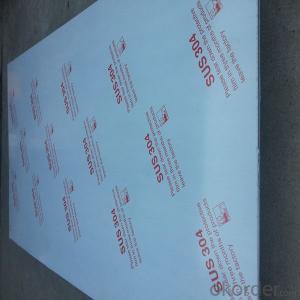

20 Gauge Stainless Steel Sheet

20 Gauge Stainless Steel Sheet Related Searches

Stainless Steel 20 Gauge Sheet 20 Gauge Stainless Steel 20 Gauge Aluminum Sheet Sheet Metal 20 Gauge 16 Gauge Stainless Steel Sheet 19 Gauge Sheet Metal Alloy 20 Stainless Steel 16g Stainless Steel Sheet 16 Gauge Sheet Steel 30 Gauge Sheet Metal Sheet Of Stainless Steel 18 Gauge Aluminum Sheet Black Stainless Steel Sheet Thin Stainless Steel Sheets Carbon Steel 20G 1 8 Stainless Steel Sheet 24 Gauge Galvanized Sheet Metal 18 Gauge Galvanized Sheet Metal 28 Gauge Galvanized Sheet Metal Stainless Steel Gauge 16 Gauge Stainless Steel Stainless Steel Sheeting 18 Gauge Stainless Steel 4 X 8 Sheet Of Stainless Steel Stainless Steel Gauge Chart 316 Stainless Steel Sheet Thin Sheet Stainless Steel Stainless Steel Sheets Price Stainless Steel Sheet Price Stainless Steel Guage Chart20 Gauge Stainless Steel Sheet Supplier & Manufacturer from China

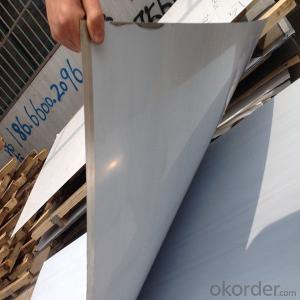

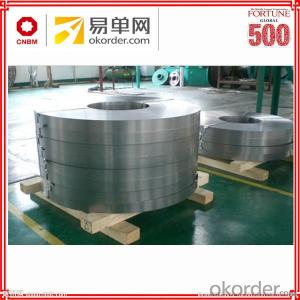

20 Gauge Stainless Steel Sheet is a versatile and durable material known for its corrosion resistance and strength. It is widely used in various industries, including construction, automotive, and food processing, due to its ability to withstand harsh environments and maintain its integrity over time. This product is particularly popular for applications where both formability and strength are required, such as in the manufacturing of appliances, architectural panels, and various industrial components.The 20 Gauge Stainless Steel Sheet is also favored for its aesthetic appeal, as it can be easily polished to a mirror-like finish, making it a popular choice for decorative purposes. Its resistance to staining and corrosion makes it an ideal material for kitchen countertops, backsplashes, and other surfaces that are frequently exposed to moisture and heat. Additionally, its non-magnetic properties and low maintenance requirements make it a preferred choice for many applications in the medical and pharmaceutical industries.

Okorder.com is a leading wholesale supplier of 20 Gauge Stainless Steel Sheet, offering a vast inventory to cater to the diverse needs of customers across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 20 Gauge Stainless Steel Sheet provided meets the highest industry standards, making it a reliable choice for businesses looking to source this material for their projects.

Hot Products