410 Stainless Steel Sheet with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel of 410 sus

Specification

Item | stainless steel of 410 sus |

Standard | ASTM,AISI,JIS,EN,DIN,GB |

Surface | 2b |

Thickness | Cold rolled:0.3mm-3mm |

Width | 1000mm/1219mm/1250mm/1500mm or as customer’s requires. |

Length | As customer’s requirements. |

Edge | Slit/Mill Edge |

Origin | TISCO,LISCO,JISCO,BAOSTEEL,BAOXIN, Eastern Special Steel etc. |

MOQ | 2 Ton |

Payment Term | 30%T/T L/C at sight |

Price Term | FOB/CFR/CIF |

Delivery | 7-10 days after the deposit |

Packaging | Seaworthy Export Standard or as customer's requests. |

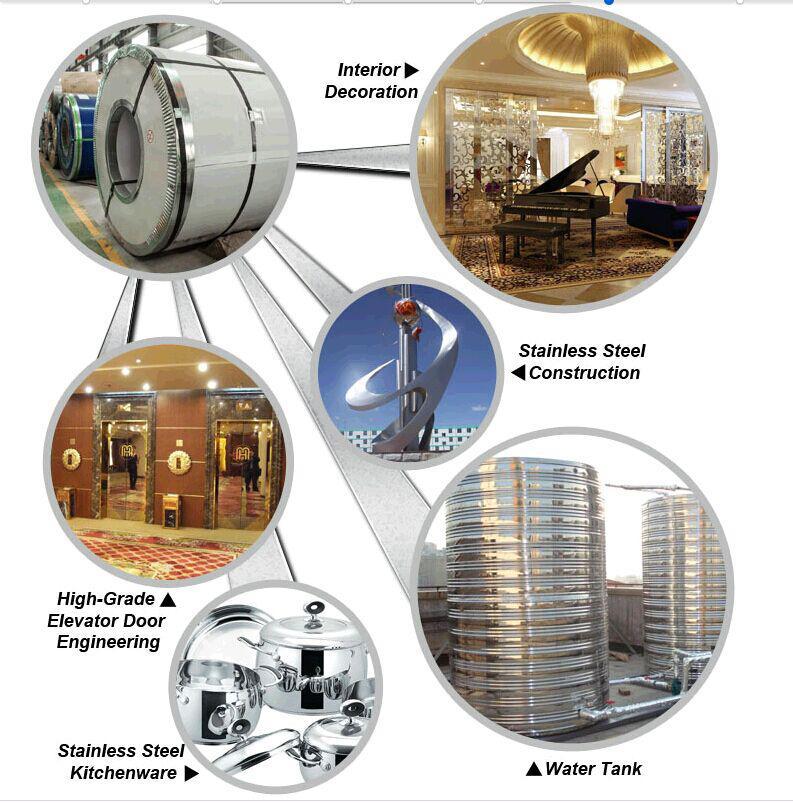

Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

Length and width combination depends on thickness and grade. Minimum quantities may apply. Please contact us for exact dimension offer.

There are high-tech equipments to processing stainless coils and sheets/plates with skilled workers.

Cut to length

Decoiling and slitting

Grinding and brushing

Film protection

Plasma and water jet cutting

Folding and embossing

Architectual Moldings and Trim

Kitchen Equipment

Textile Paper

Pharmaceutical and

Chemical Industry Processing Euipment

Company Information

Our supplier produce a variety of products including bar, rod, wire, angles, plate, sheet and strip, in stainless steel ad other specialty steels.

We are specialized in this line for years.These are our cooperating countries :India, Bangladesh, USA, Vietnam, Iran, Ecuador, UAE, Algeria, Hungary etc.

Please rest assured that the quality and experience are ensured.

Main: 310 s, 316 l, 201, 202, 304, 304 l, 321, 316, 309 s such as thin, medium and thick plate, also according to the special needs of users, stainless steel order to undertake various special specifications of the stainless steel.

Certification

Our company has passed the SGS certification, and we have good reputation in the line of export of stainless steel.

Packaging & Shipping

| Packing details | 800 Ton/Tons per Day |

| Export standard package :bundled wooden box or be required | |

| Port:shanghai | |

| Delivery Time | 15 working days |

| Payment Terms | L/C ,T/T , western union , paypal , alipay |

| Shipping | DHL , UPS , FEDEX , TNT , EMS , by air , by sea , China post , any way you think is suitable |

eel plate

Our Services

stainless steel sheet

1.Professional person communicate with you before the order

2.OEM&ODM, also provide customized service

3.Offer for your unique design and some our current model

4.Protection of your sales area, ideas of design and all your private information

5.Provide strict quality check for each part,each process before export

6.Provide complete post-sale service,including installation,technical guide

Explore for more product information Leave an inquiry t know more details about price,packing,shipping and discount.

- Q: What are the different types of stainless steel sheet surface treatments available?

- There are several different types of stainless steel sheet surface treatments available, each offering unique benefits and appearances. Some of the most common surface treatments include: 1. No.1 Finish: This is a hot-rolled, annealed, and pickled surface finish that is commonly used for industrial applications. It has a rough texture with visible grain lines. 2. No.2B Finish: Also known as a bright, cold-rolled finish, it is obtained by annealing and pickling. It provides a smooth and reflective surface with a moderate level of gloss. 3. No.3 Finish: This is a finely polished surface obtained by using gradually finer abrasive materials. It has a semi-reflective appearance and is often used for decorative applications. 4. No.4 Finish: Similar to No.3 finish, but with a higher level of polish. It has a satin-like appearance and is commonly used in architectural and kitchen equipment applications. 5. BA (Bright Annealed) Finish: This is a mirror-like, highly reflective finish achieved by annealing the stainless steel sheet in a controlled atmosphere. It is commonly used for decorative purposes and in the production of household appliances. 6. Embossed Finish: This treatment involves stamping the stainless steel sheet with a pattern to create a textured surface. It is often used for decorative purposes or to provide grip on surfaces. 7. Colored Finish: Stainless steel sheets can also be treated with different colored coatings, such as gold, black, or bronze. These finishes are achieved through processes like PVD (Physical Vapor Deposition) or electroplating. Each surface treatment offers its own advantages and is suitable for specific applications. It is important to consider factors such as durability, corrosion resistance, aesthetic appeal, and intended use when selecting the appropriate surface treatment for a stainless steel sheet.

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets typically come with a warranty. The length and terms of the warranty may vary depending on the manufacturer or supplier. It is recommended to check with the specific company or review the product documentation for information on the warranty coverage.

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Yes, stainless steel sheets can be used for mezzanine flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for various applications including flooring. It has high strength and can withstand heavy loads, making it ideal for mezzanine structures. Additionally, stainless steel sheets can be easily cleaned and maintained, ensuring a hygienic and aesthetically pleasing flooring option.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel is a universal stainless steel material, antirust performance than the 200 series of stainless steel material stronger. High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment due to their excellent corrosion resistance, hygienic properties, and durability. Stainless steel is resistant to rust and corrosion caused by exposure to water, steam, and various chemicals commonly used in breweries. It can withstand high temperatures during brewing processes without degrading or affecting the taste of the final product. Additionally, stainless steel is easy to clean and maintain, ensuring the equipment remains sanitary and meets the strict hygiene standards required in the brewing industry.

- Q: What is the modulus of elasticity of stainless steel sheets?

- The modulus of elasticity, also known as Young's modulus, is a measure of the stiffness or rigidity of a material. For stainless steel sheets, the modulus of elasticity typically ranges from 190 to 200 gigapascals (GPa). However, it is important to note that the modulus of elasticity can vary depending on the specific type and grade of stainless steel, as well as factors such as temperature and strain rate.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness of stainless steel sheets varies depending on the specific type and grade of stainless steel. Typically, stainless steel sheets are available in thicknesses ranging from 0.4mm to 6.0mm. Thinner sheets are commonly utilized for flexible and lightweight applications, whereas thicker sheets are typically employed for structural purposes requiring increased strength and durability. It is worth mentioning that customized thicknesses can be manufactured to meet specific project requirements.

- Q: What are the different types of stainless steel sheet alloys?

- There are several different types of stainless steel sheet alloys, each with their own unique properties and characteristics. Some of the most common types include: 1. Austenitic stainless steel: This is the most widely used type of stainless steel sheet alloy. It is known for its high corrosion resistance and excellent formability. Austenitic stainless steel grades include 304 and 316, which are commonly used in various industries such as food processing, pharmaceuticals, and architecture. 2. Ferritic stainless steel: This type of stainless steel sheet alloy has a higher carbon content and lower chromium content compared to austenitic stainless steel. Ferritic stainless steel is known for its good corrosion resistance and high strength. It is often used in applications where high temperature resistance is required, such as automotive exhaust systems. 3. Martensitic stainless steel: Martensitic stainless steel sheet alloys have a higher carbon content and lower chromium content compared to both austenitic and ferritic stainless steels. They are known for their high strength and hardness, as well as their good corrosion resistance. Martensitic stainless steel grades are commonly used in applications such as cutlery, surgical instruments, and turbine blades. 4. Duplex stainless steel: This type of stainless steel sheet alloy is a combination of austenitic and ferritic stainless steels. It offers a good balance of strength and corrosion resistance, making it suitable for a wide range of applications. Duplex stainless steel grades are commonly used in the chemical processing, oil and gas, and marine industries. 5. Precipitation-hardening stainless steel: This type of stainless steel sheet alloy is heat treatable and can achieve high strength and hardness through a precipitation-hardening process. Precipitation-hardening stainless steel is commonly used in aerospace and defense applications, where high strength and corrosion resistance are critical. These are just a few examples of the different types of stainless steel sheet alloys available. The choice of alloy depends on the specific application requirements, such as corrosion resistance, strength, and temperature resistance.

- Q: Can stainless steel sheets be used in high-pressure applications?

- Yes, stainless steel sheets can be used in high-pressure applications. Stainless steel is known for its excellent corrosion resistance and high strength, making it suitable for various industrial applications including high-pressure environments. The high strength of stainless steel allows it to withstand the force exerted by high-pressure fluids or gases without deforming or failing. Additionally, stainless steel sheets can be fabricated into different shapes and sizes, enabling their use in a wide range of high-pressure applications such as pressure vessels, pipelines, hydraulic systems, and heat exchangers. Overall, stainless steel sheets are a reliable and durable choice for high-pressure applications due to their inherent strength and corrosion resistance properties.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets can be cleaned and maintained by using a mild detergent or vinegar solution and a soft cloth to wipe away any dirt or stains. It is important to avoid using abrasive cleaners or scrub brushes that could scratch the surface. Regular cleaning and drying with a soft cloth can help prevent water spots and maintain the shine of the stainless steel. Additionally, avoiding contact with harsh chemicals or acids can help prevent corrosion or damage to the sheets.

Send your message to us

410 Stainless Steel Sheet with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords