Galvanized Steel Coil with Best Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

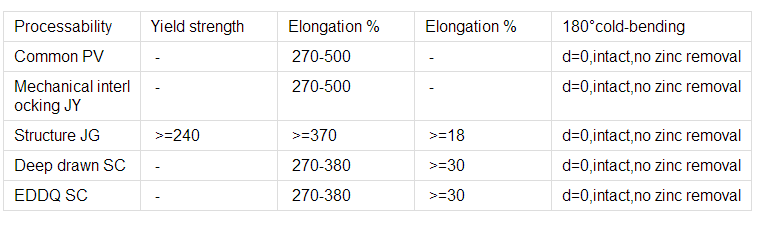

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How do I calculate the strength of stainless steel sheets?

- To determine the strength of stainless steel sheets, various factors need to be taken into account, including tensile strength, yield strength, and elongation. Tensile strength refers to the maximum stress a material can handle before breaking and is typically measured in psi or MPa. To ascertain the tensile strength of stainless steel sheets, one can refer to the manufacturer's specification sheet or consult engineering handbooks. Yield strength, on the other hand, denotes the stress at which a material permanently deforms. It is a crucial consideration in structure design and material selection. The yield strength of stainless steel sheets can be found in the manufacturer's specification sheet or engineering references. Elongation, expressed as a percentage, indicates the extent to which a material can stretch or deform before breaking. Higher elongation values signify greater ductility. The elongation of stainless steel sheets can be determined through tensile testing or obtained from material specifications. These three parameters, namely tensile strength, yield strength, and elongation, offer valuable insights into the overall strength and performance of stainless steel sheets. It is imperative to consider these factors when assessing the suitability of stainless steel sheets for specific applications or designing structures that require a particular strength level.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent galvanic corrosion on stainless steel sheets: 1. Opt for a suitable stainless steel alloy: Select a grade of stainless steel, such as 316 or 317, which is less susceptible to galvanic corrosion compared to 304 stainless steel. 2. Keep dissimilar metals separate: Avoid direct contact between stainless steel sheets and other metals, particularly those with a higher potential for galvanic corrosion. If contact is necessary, use insulating materials like gaskets or rubber pads to create a barrier between the metals. 3. Apply protective coatings: Use specially designed protective coatings or paints for stainless steel to create a barrier that shields against galvanic corrosion. These coatings act as sacrificial layers, safeguarding the stainless steel from direct contact with corrosive substances. 4. Utilize isolation materials: Install insulating materials, such as plastic washers, insulating tape, or non-conductive gaskets, between stainless steel sheets and other dissimilar metals. This prevents direct electrical contact and subsequent corrosion. 5. Maintain proper upkeep: Regularly clean and inspect stainless steel sheets to remove any contaminants or foreign substances that may contribute to corrosion. Avoid using abrasive cleaners or tools that could damage the protective layer of the stainless steel. 6. Employ electrochemical protection: Implement cathodic protection techniques, such as sacrificial anodes or impressed current systems, to introduce an external source of electrons that counteracts galvanic corrosion. These methods help shift the corrosion potential of the stainless steel sheets to a more passive range. By adhering to these preventive measures, the risk of galvanic corrosion on stainless steel sheets can be significantly reduced. This ensures their longevity and helps maintain their structural integrity.

- Q: Are stainless steel sheets suitable for power plant equipment?

- Indeed, power plant equipment can be suitably constructed using stainless steel sheets. Renowned for its exceptional resistance to corrosion, robust strength, and enduring nature, stainless steel is a favored option across a multitude of industries, including power plants. Given that power plants often encounter challenging conditions characterized by elevated temperatures, intense pressure, and corrosive agents, stainless steel effectively withstands such environments. Furthermore, it exhibits commendable heat resistance, thereby ensuring the maintenance of its structural integrity even at heightened temperatures, a vital attribute for power plant equipment. Moreover, stainless steel sheets can be readily manipulated and welded to conform to specific design prerequisites for power plant equipment, thus rendering them both versatile and dependable.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are indeed suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity, which allows for efficient heat transfer. It also has high corrosion resistance and can withstand high temperatures, making it a reliable choice for various heat transfer applications.

- Q: Can stainless steel sheets be used for water pipelines?

- Yes, stainless steel sheets can be used for water pipelines. Stainless steel is highly resistant to corrosion and has excellent strength, making it a suitable material for water pipelines that require durability and longevity. Additionally, stainless steel's smooth surface helps to maintain water flow efficiency and prevent contamination.

- Q: Stainless steel plate laser cutting how to charge?

- Charge standard: according to the material thickness of /1 meters, for example, 1mm thick steel, about 6 yuan / M

- Q: What are the different types of stainless steel sheet finishes for sanitary applications?

- There are several types of stainless steel sheet finishes commonly used for sanitary applications, including #4 brushed finish, #8 mirror finish, and bead blast finish. The #4 brushed finish provides a smooth and uniform appearance with a slight texture, making it resistant to scratches and easy to clean. The #8 mirror finish is highly reflective and has a polished surface, making it aesthetically appealing and suitable for applications where hygiene is crucial. The bead blast finish has a matte texture with a uniform grain, offering a non-reflective surface that is resistant to fingerprints and often used in high-traffic areas.

- Q: Are stainless steel sheets suitable for solar panel frames?

- Yes, stainless steel sheets are suitable for solar panel frames. Stainless steel is known for its durability, corrosion resistance, and ability to withstand extreme weather conditions, making it a reliable material for supporting and protecting solar panels. Its strength-to-weight ratio also makes it ideal for constructing lightweight yet sturdy frames that can withstand the rigors of outdoor installations.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

- Q: Can stainless steel sheets be cut to custom sizes?

- Yes, stainless steel sheets can be cut to custom sizes.

Send your message to us

Galvanized Steel Coil with Best Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords