Plastic Coated Steel Roofing Sheets

Plastic Coated Steel Roofing Sheets Related Searches

Green Plastic Roofing Sheets Fitting Corrugated Plastic Roofing Sheets Galvanised Steel Corrugated Roofing Sheets Pp Roofing Sheets Structural Plastic Sheets Roofing Plywood Sheets Corrigated Plastic Roofing Protective Plastic Sheeting Polycarbonate Sheet Roofing Colored Plastic Sheeting Rolls Corrugated Shed Roof Sheets Fitting Polycarbonate Roofing Sheets Plastic Film Sheets Corrugated Felt Roof Sheets House Roof Sheets Coroline Roofing Sheets Garden Plastic Sheeting Fiberglass Sheets For Roofing Imitation Slate Roofing Sheets Clear Corrugated Plastic Roofing Stone Coated Steel Roof Colour Roofing Sheet Pvc Roofing Sheets Price Lightweight Plastic Sheets Thin Stainless Steel Sheets Stainless Steel Sheeting Thin Hard Plastic Sheets Large Rolls Of Plastic Sheeting Stainless Steel Roofing Conservatory Plastic Roof PanelsPlastic Coated Steel Roofing Sheets Supplier & Manufacturer from China

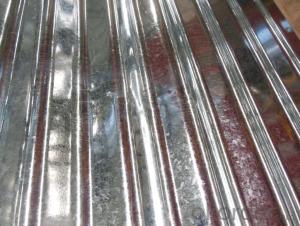

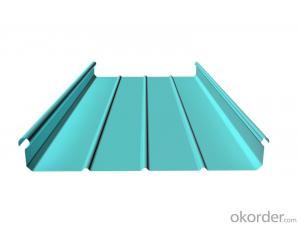

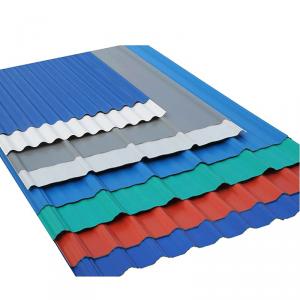

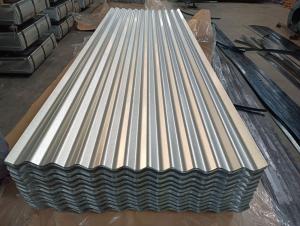

Plastic Coated Steel Roofing Sheets are a type of roofing material that combines the durability of steel with the protective qualities of plastic coating. This unique combination results in a lightweight, yet robust roofing solution that offers excellent resistance to weather conditions and corrosion. These sheets are designed to provide long-lasting protection for various structures, making them an ideal choice for both residential and commercial buildings.Plastic Coated Steel Roofing Sheets are widely used in various construction projects due to their versatility and adaptability. They can be easily installed on different roof types, including pitched and flat roofs, and are suitable for a range of climates and weather conditions. This product is particularly popular in regions with harsh weather, as the plastic coating provides an extra layer of protection against rain, snow, and UV rays. Additionally, the steel core ensures that the sheets maintain their shape and strength, even under heavy loads or extreme temperature fluctuations.

Okorder.com is a leading wholesale supplier of Plastic Coated Steel Roofing Sheets, offering a vast inventory of this high-quality roofing material. Our extensive range of products caters to the diverse needs of our customers, ensuring that we can provide the perfect solution for any project. By partnering with Okorder.com, you can benefit from our competitive prices, fast shipping, and exceptional customer service, making the procurement of Plastic Coated Steel Roofing Sheets a hassle-free experience.

Hot Products