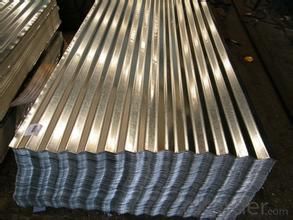

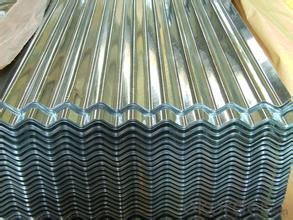

Galvanized Corrugated Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Size

corrugated steel sheet

thickness:0.14-0.8mm

full hard quanlity

reasonable corrugated metal price

ISO:9001:2000

Introduction

Corrugated Steel Sheet is made of quality galvanized steel sheet with automatic press-forming process. It features on light weight, easy installation, fire proof, water proof, long lift-span, etc...

Specifications

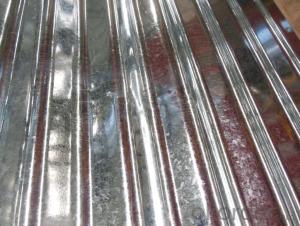

Classification Coating Product Characteristics

Hot dip galvanizing

Zinc coated by hot dip galvanizing; Light coated products have good weldability and formability; Usable from general

processing to deep drawing according to application; Heavy coated products have superior corrosion resistance; Wide

application are possible by selecting spangle or a post treatment.

Applications

Galvanized Corrugated Steel Sheets are used in construction of warehouses, industrial sheds, military establishments,

etc. It is used as roofing material in many buildings, railway stations, waiting zones etc. Thick zinc coating and corrugated

channels makes it water resistant and thus very useful in construction and temporalty establishments.

Our Range of Products

Our wide range of roofing products consists of Trapezoidal Profile, Mandarin Tile, Wall Cladding Corrugation Profile,

and variety of accessories like Flashings, Ridges, Gutters, etc.

- Q: What is the tensile strength of steel sheets?

- The tensile strength of steel sheets typically ranges from 370 to 520 megapascals (MPa), depending on the grade and thickness of the steel.

- Q: Can the steel sheets be painted or coated?

- Indeed, it is possible to paint or coat steel sheets. Diverse industries often engage in the practice of painting or coating steel sheets to enhance visual appeal, guard against corrosion, and bolster durability. Prior to any application of paint or coating, it is crucial to thoroughly cleanse and prepare the steel surface to ensure proper adhesion. The choice of paint or coating depends on the desired finish, environmental conditions, and specific application. It is imperative to select a paint or coating that is compatible with the steel substrate and capable of enduring the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may impact the performance and lifespan of the coating.

- Q: What are the different quality standards for steel sheets?

- Steel sheets must meet specific requirements and be suitable for their intended use, which is why there are several quality standards in place. Some of the most common standards for steel sheets are as follows: 1. Carbon structural steel sheets used for general structural purposes are regulated by ASTM A36/A36M. This standard outlines the material's chemical composition, mechanical properties, and other relevant factors. 2. ASTM A568/A568M covers the general requirements for steel sheet products, including hot-rolled, cold-rolled, and coated sheets. It provides specifications for dimensions, tolerances, and surface quality. 3. EN 10130 specifies the requirements for cold-rolled low carbon steel flat products, including steel sheets, in Europe. It outlines the material's chemical composition, mechanical properties, and other relevant factors. 4. JIS G 3302 is a Japanese industrial standard that covers the requirements for hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. 5. ISO 3574 is an international standard that specifies the requirements for cold-reduced carbon steel sheet of commercial and drawing qualities. It provides guidelines for dimensions, tolerances, and mechanical properties. 6. GB/T 2518 is a Chinese national standard that outlines the requirements for continuous hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. These quality standards ensure that steel sheets have consistent properties and characteristics, making them suitable for various applications such as construction, automotive, manufacturing, and more. Manufacturers, suppliers, and end-users must adhere to these standards to guarantee the quality and reliability of steel sheet products.

- Q: What is the typical impact resistance of a steel sheet?

- The typical impact resistance of a steel sheet can vary depending on various factors such as the type and grade of steel, thickness of the sheet, and the specific conditions of impact. However, steel sheets are generally known for their high impact resistance due to the material's strength and durability.

- Q: How do steel sheets compare to aluminum sheets in terms of weight?

- Steel sheets are generally heavier than aluminum sheets.

- Q: How do steel sheets perform in low-temperature environments?

- Steel sheets generally perform well in low-temperature environments. The mechanical properties of steel, such as strength and toughness, are not significantly affected by low temperatures. Steel has a low coefficient of thermal expansion, which means it does not contract or expand drastically when subjected to temperature variations. This property allows steel sheets to maintain their shape and structural integrity in cold conditions. Moreover, steel is also highly resistant to brittle fracture at low temperatures. It has a good impact resistance, meaning it can absorb energy without fracturing. This makes steel sheets suitable for applications in low-temperature environments where materials need to withstand heavy loads or sudden impacts, such as in cold storage facilities or offshore structures in Arctic regions. However, it is worth noting that some types of steel, particularly those with high carbon content or low alloy steels, can exhibit reduced toughness and ductility at extremely low temperatures. In such cases, special precautions may be necessary, such as using steel grades specifically designed for low-temperature applications or implementing proper insulation measures to prevent rapid temperature changes. Overall, steel sheets are generally reliable and perform well in low-temperature environments due to their strength, toughness, and resistance to brittle fracture. However, the specific performance of steel in cold conditions may vary depending on the composition and quality of the steel used.

- Q: Can steel sheets be used for automotive body panels?

- Yes, steel sheets can be used for automotive body panels. Steel is a common material choice for car body panels due to its strength, durability, and ability to withstand impact. It provides structural integrity and protection to the vehicle's occupants while also allowing for customization and design flexibility.

- Q: Are steel sheets resistant to termite infestation?

- Steel sheets do not possess resistance against termite infestation. Although termites primarily consume wood and other cellulose-based materials, they can indirectly harm steel structures. Termites are capable of tunneling through various substances like concrete or insulation in order to access the wooden parts of a construction. Consequently, even though termites may not directly affect the steel sheets themselves, they can still jeopardize the overall stability of a building or structure if they manage to infiltrate the wooden components. Hence, it is crucial to implement preventative measures, conduct regular inspections, and apply treatments to vulnerable areas to safeguard against termite infestation, regardless of the presence of steel sheets.

- Q: What is the cost of steel sheets compared to other materials?

- The price of steel sheets can vary depending on factors such as the type of material, size, thickness, and market conditions. Typically, steel sheets are pricier than materials like aluminum or plastic, but they are renowned for their durability and strength. Industries like construction, automotive, and manufacturing commonly utilize steel sheets due to their ability to bear heavy loads and resist corrosion. Although steel sheets may have a higher initial cost, they often have a longer lifespan and require less maintenance compared to other materials. Furthermore, the cost of steel sheets can change based on global supply and demand dynamics, as well as any tariffs or trade restrictions that affect the steel market.

- Q: How do steel sheets handle thermal conductivity?

- Steel sheets possess a relatively high level of thermal conductivity, which indicates their effectiveness in the transmission of heat. This characteristic enables steel to rapidly absorb and spread heat across its entirety. When subjected to a heat source, like a flame or hot object, steel sheets swiftly conduct the heat throughout their structure, resulting in consistent heating or cooling. Consequently, steel sheets are well-suited for applications demanding heat transfer, such as radiant heating systems in the construction industry or heat exchangers in manufacturing. The elevated thermal conductivity of steel also renders it a favored material for cookware, as it guarantees uniform heat distribution and efficient cooking. However, it is crucial to acknowledge that steel's thermal conductivity can also make it susceptible to heat loss in colder environments, necessitating appropriate insulation measures to uphold desired temperatures.

Send your message to us

Galvanized Corrugated Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords