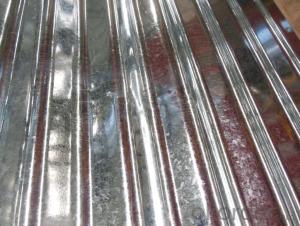

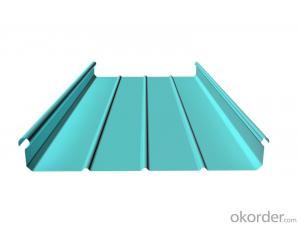

Corrugated Galvanized Steel Sheet Metal Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Corrugated Galvanized Steel Sheet Metal Roofing Sheet

Specification of the Corrugated Galvanized Steel Sheet Metal Roofing Sheet

| NAME | PPGI | GALVANIZED | GALVALUME/ZINCALUME |

| CERTIFICATE | ISO9001:2008 | ||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653M JIS G3302 GB/T2518 EN 10142 | ASTM A792M JIS G3321 JIS G3317 EN 10215 |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 | DX51D+Z/DX52D+Z/S250GD+Z S300GD+Z/S350GD+Z/S550GD+Z SGCC/SGCH/SGCD1-SGCD3/SGC340-SGC570 G2+Z/G3+Z/G250+Z/G300+Z G350+Z/G550+Z | DX51D+AZ/DX52D+AZ/S250GD+AZ S300GD+AZ/S350GD+AZ/S550GD+AZ SGLCC/SGLCD/SGLC300-SGLC570 G2+AZ/G3+AZ/G250+AZ/G300+AZ G350+AZ/G550+AZ |

| COATING | RAL COLOURS | Z60g/m2 to Z275g/m2 | AZ30g/m2 to AZ150g/m2 |

| SIZE | (0.13mm-1.5mm)X1000mm OR as requirements | (0.13mm-4.0mm)X1500mm OR as requirements | (0.12mm-4.0mm)X1500mm OR as requirements |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled -galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLER SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled,TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint,Coating | |

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds; Outer clad sheets for washing machine, refrigerator, televi-sion, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts; Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in high -way; Electric control cabinet, industrial refrigeration equipment, automatic vending machine; Wear resistant steel, high- strength - steel plate | ||

Supplier of the Corrugated Galvanized Steel Sheet Metal Roofing Sheet

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Delivery of the Corrugated Galvanized Steel Sheet Metal Roofing Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

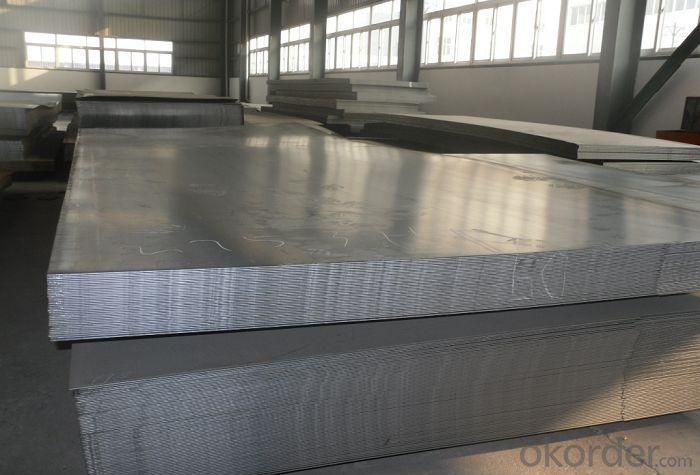

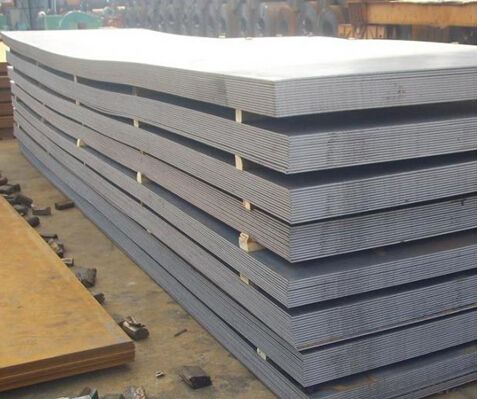

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the automotive suspension spring industry?

- Enhanced performance and durability in the automotive suspension spring industry are provided by special steel, which plays a crucial role. These springs bear the weight of the vehicle and absorb road shocks, ensuring a smooth and comfortable ride for passengers. Also known as alloy steel, special steel is specifically designed to possess exceptional mechanical properties. These include high strength, toughness, and resistance to wear and fatigue. Such properties are vital for suspension springs, as they must endure the constant stresses and strains of vehicle operation. The utilization of special steel in automotive suspension springs allows for the production of lighter yet stronger and more reliable springs compared to traditional steel ones. Consequently, this leads to improved fuel efficiency, reduced vehicle weight, lower emissions, and a more sustainable automotive industry. Moreover, special steel enables suspension springs to maintain their shape and performance over extended periods, even under extreme conditions. This ensures that the vehicle's suspension system remains effective, providing a stable and comfortable driving experience. Additionally, special steel can be customized to meet the specific requirements of different vehicles. This allows for the tailoring of suspension springs based on factors such as vehicle weight, load capacity, and desired ride quality. The flexibility in material properties enhances the overall performance and safety of the suspension system. In summary, special steel is essential in the automotive suspension spring industry as it provides the necessary strength, durability, and performance characteristics for a reliable and efficient suspension system. Its use contributes to the development of lighter, more fuel-efficient vehicles while ensuring passenger comfort and safety.

- Q: What are the main factors affecting the cost of special steel?

- The main factors affecting the cost of special steel include the cost of raw materials, such as iron ore and alloying elements, production and manufacturing costs, market demand and competition, transportation and logistics expenses, and global economic factors such as currency exchange rates and trade policies. Additionally, the complexity and uniqueness of the steel's composition and processing requirements can also impact its cost.

- Q: How is special steel used in the production of hydraulic components?

- Special steel is used in the production of hydraulic components due to its high strength, corrosion resistance, and ability to withstand extreme pressure and temperature conditions. It helps in manufacturing durable and reliable hydraulic parts such as cylinders, valves, fittings, and pistons, ensuring efficient functioning and long-lasting performance of hydraulic systems.

- Q: How is special steel used in the manufacturing of cutting tools?

- Special steel is used in the manufacturing of cutting tools because of its high hardness, toughness, and wear resistance. This type of steel can be heat-treated to achieve the desired hardness and can retain its cutting edge for a longer period. It is commonly used in the production of drills, saw blades, and milling cutters to ensure efficient and precise cutting operations.

- Q: What are the common challenges in heat treating titanium alloys?

- Heat treating titanium alloys can present several common challenges. One of the main challenges is the high reactivity of titanium with oxygen, nitrogen, and hydrogen at elevated temperatures. This reactivity can lead to surface contamination and the formation of undesirable oxides, nitrides, or hydrides, which can affect the mechanical properties of the alloy. Another challenge is the formation of alpha-case, a thick layer of alpha-phase titanium on the surface of the alloy during heat treatment. Alpha-case is brittle and can significantly reduce the fatigue strength and ductility of the material. Therefore, minimizing or eliminating the formation of alpha-case is crucial in heat treating titanium alloys. Furthermore, titanium alloys have a narrow temperature range for effective heat treatment. If the temperature is too low, it may not achieve the desired microstructure and mechanical properties. On the other hand, if the temperature is too high, it can lead to grain growth, which can reduce the strength and toughness of the alloy. Additionally, the heat treatment of titanium alloys often requires precise control of the heating and cooling rates to achieve the desired microstructure and properties. Rapid or uneven cooling can result in non-uniform microstructures, residual stresses, or distortion of the part. Finally, the cost of heat treating titanium alloys can be a challenge. Titanium alloys have a high affinity for oxygen, which necessitates the use of specialized equipment, such as vacuum furnaces or controlled atmosphere furnaces, to maintain a low oxygen environment. These specialized heat treatment processes can be expensive and require careful handling and maintenance to ensure the desired results. In conclusion, the common challenges in heat treating titanium alloys include managing reactivity with oxygen, nitrogen, and hydrogen, minimizing alpha-case formation, achieving the correct temperature range, controlling heating and cooling rates, and dealing with the cost of specialized equipment and processes. Overcoming these challenges is essential to obtain high-quality titanium alloy components with desired properties.

- Q: What is the significance of special steel in the medical field?

- Special steel, which is also referred to as medical grade steel, holds a vital role in the medical field due to its distinct properties and importance. Specifically designed and produced to meet the strict requirements of the healthcare industry, special steel's significance in the medical field can be grasped through the following points: 1. Biocompatibility: Special steel demonstrates biocompatibility, meaning it is non-toxic and does not elicit an adverse reaction when it comes into contact with the human body. This makes it an ideal material for medical devices like surgical instruments, implants, and orthopedic tools. 2. Resistance to corrosion: Special steel exhibits high resistance to corrosion and rust, ensuring the endurance and durability of medical instruments. Instruments used in surgical procedures require repeated sterilization, and the corrosive nature of sterilization agents can degrade ordinary steel. Special steel, with its superior resistance to corrosion, can withstand these harsh conditions, decreasing the risk of contamination and preserving the integrity of medical equipment. 3. Mechanical properties: Special steel possesses exceptional mechanical properties, such as high strength, toughness, and ductility. These characteristics are crucial for medical devices as they need to endure the stresses and strains of surgical procedures, maintain their shape, and deliver reliable performance. 4. Compatibility with sterilization: Special steel can withstand various sterilization methods, including steam sterilization, ethylene oxide sterilization, and gamma radiation. This guarantees that medical instruments made from special steel can be effectively sterilized, preventing the transmission of infections and minimizing the risk of contamination during surgeries. 5. Precision manufacturing: Special steel can be shaped into intricate forms and sizes, enabling the production of precise medical instruments. Its superior machinability allows for the creation of fine and sharp edges, which are vital for surgical tools used in delicate procedures. 6. Antibacterial properties: Certain special steels, such as stainless steel, possess inherent antibacterial properties. This characteristic is particularly crucial in the medical field, where preventing infections is of utmost importance. Instruments made from antibacterial special steel can hinder the growth of bacteria, minimizing the risk of post-operative complications. In conclusion, the significance of special steel in the medical field lies in its biocompatibility, resistance to corrosion, mechanical properties, compatibility with sterilization, precision manufacturing, and potential antibacterial properties. These qualities render special steel an indispensable material for the manufacturing of medical devices, ensuring their dependability, durability, and safety for both healthcare professionals and patients.

- Q: How does quenching and tempering affect the hardness of special steel?

- Special steel can have its hardness and mechanical properties improved through the use of heat treatment processes known as quenching and tempering. During quenching, the steel undergoes rapid cooling from a high temperature to either room temperature or below. This is typically achieved by immersing the steel in a quenching medium like oil or water. The quick cooling results in the formation of a martensitic structure, which is characterized by high hardness and brittleness. Quenching significantly enhances the hardness of the steel. However, the brittleness of the martensitic structure limits its usability in many applications. To address this issue, the steel then undergoes tempering. Tempering entails reheating the quenched steel to a temperature below the lower critical temperature, usually ranging from 200 to 600 degrees Celsius. The steel is held at this temperature for a specific period of time. This process facilitates the transformation of the brittle martensite into a more ductile structure known as tempered martensite. Tempering reduces the hardness of the steel but imparts improved toughness and ductility. The actual hardness achieved after tempering depends on the tempering temperature and time. Higher temperatures and longer times result in a greater reduction in hardness. By carefully adjusting the tempering parameters, a balance between hardness and toughness suitable for the intended application can be achieved. To summarize, quenching and tempering have a significant impact on the hardness of special steel. Quenching increases hardness by creating a martensitic structure, while tempering reduces hardness but enhances toughness and ductility. The specific hardness achieved through these processes can be controlled by adjusting the quenching and tempering parameters to meet the desired mechanical properties for the specific application.

- Q: How long does special steel last compared to regular steel?

- Special steel generally lasts longer than regular steel due to its unique composition and properties. Regular steel is made mostly of iron and carbon, whereas special steel is alloyed with other elements such as chromium, nickel, and molybdenum to enhance its strength, hardness, and corrosion resistance. The lifespan of special steel depends on various factors such as the specific type of steel, its usage conditions, and maintenance. However, in general, special steel can have a significantly longer lifespan compared to regular steel. It is more resistant to wear and tear, corrosion, and high temperatures, making it suitable for demanding applications and environments. For instance, in industries such as aerospace, automotive, and construction, special steel is widely used for critical components like engine parts, structural elements, and cutting tools. These components often experience high stress, friction, and exposure to harsh conditions. Special steel's superior properties enable it to withstand these challenges and maintain its performance over a longer period of time. Moreover, special steel is often subjected to rigorous testing and quality control measures during its manufacturing process. This ensures that it meets specific industry standards and can endure extreme conditions without significant degradation. Regular steel, on the other hand, may not possess the same level of durability or longevity. In summary, while the exact lifespan of special steel compared to regular steel can vary depending on various factors, special steel generally lasts longer due to its enhanced properties and resistance to wear, corrosion, and high temperatures.

- Q: What are the requirements for special steel used in metalworking tools?

- The requirements for special steel used in metalworking tools include high hardness, excellent wear resistance, good toughness, and high heat resistance. Additionally, the steel should have good machinability, be able to hold a sharp edge, and have the ability to withstand high temperatures and loads without deforming or breaking.

- Q: How is high-strength steel used in the automotive industry?

- High-strength steel is widely used in the automotive industry for its ability to enhance the safety and performance of vehicles. It is used in various components such as the frame, chassis, and body structure to improve structural integrity, reduce weight, and provide better crash protection. Additionally, high-strength steel allows automakers to design vehicles with improved fuel efficiency and increased load-carrying capacity, making it a crucial material in modern automotive manufacturing.

Send your message to us

Corrugated Galvanized Steel Sheet Metal Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords