All Categories

- - Steel Wire Rod

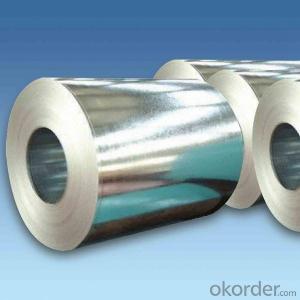

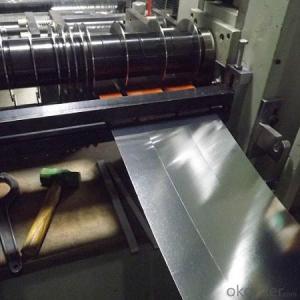

- - Steel Coils

- - Steel Profiles

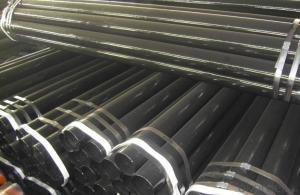

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

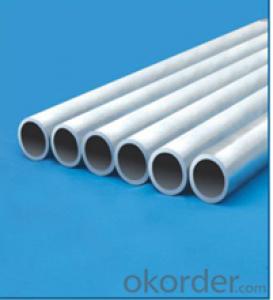

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Steel Wire RodView More

Steel CoilsView More

Steel ProfilesView More

Steel PipesView More

Stainless SteelView More

TinplateView More

Special SteelView More

Steel SheetsView More

Steel RebarsView More

Steel StripsView More

Hot Rolled SteelView More

Cold Rolled SteelView More

Pre-painted SteelView More

Seamless Steel PipeView More

Welded Steel PipeView More

Hollow Steel TubesView More

Galvanized PipeView More

Stainless Steel CoilView More

Stainless Steel SheetView More

Stainless Steel PlateView More

Stainless Steel StripsView More

Electrolytic Tinplate CoilView More

Electrolytic Tinplate SheetView More

Stainless Steel RebarsView More

Q & A

What are the advantages of using steel in the production of bridges and tunnels?

There are several advantages of using steel in the production of bridges and tunnels. Firstly, steel is known for its strength and durability, making it an ideal material to withstand heavy loads and harsh environmental conditions, ensuring the longevity of the structure. Secondly, steel is highly versatile, allowing for flexibility in design and construction, accommodating different shapes and sizes to meet specific project requirements. Additionally, steel is lightweight compared to other materials like concrete, which facilitates easier transportation and installation. Moreover, steel is a sustainable choice as it can be recycled, reducing environmental impact and promoting a circular economy. Lastly, steel structures are often cost-effective, as they can be fabricated off-site and assembled quickly, minimizing labor and construction time. Overall, the use of steel in bridges and tunnels provides structural integrity, design flexibility, sustainability, and cost efficiency.

What are the various steel grades, and how are they classified?

There are numerous steel grades, each with its own unique properties and applications. Steel grades are typically classified based on their chemical composition and physical properties. Some common steel grades include carbon steel, alloy steel, stainless steel, tool steel, and weathering steel. These grades are further categorized into specific classes or types based on their specific attributes, such as strength, ductility, corrosion resistance, and heat resistance.

How is steel tested for quality and strength?

Steel is tested for quality and strength through a variety of methods, including physical and mechanical tests. These tests typically involve assessing its hardness, tensile strength, impact resistance, and ability to withstand pressure or deformation. Additionally, chemical analysis is conducted to ensure the steel meets specific composition standards. These rigorous testing procedures help determine whether the steel is of high quality and possesses the required strength for its intended applications.

Wholesale Steel from supplier in Uganda

We are a Steel supplier serving the Uganda, mainly engaged in the sale, quotation, and technical support services of various Steel products in the Uganda region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel procurement services in the Uganda. Not only do we have a wide range of Steel products, but after years of market development in the Uganda, we can also provide valuable experience for your projects.