Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Smart appearance with subtle square fluting

Anti-capillary groove ensures leak-proof roof

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

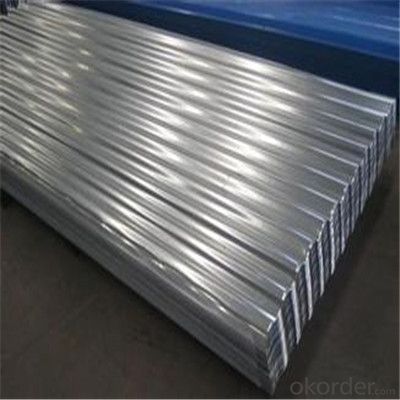

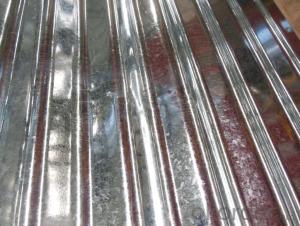

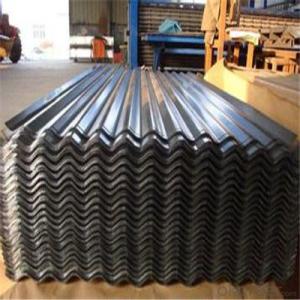

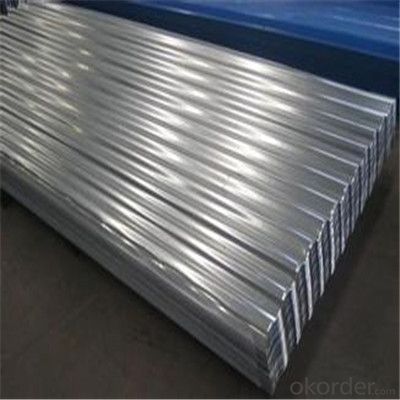

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for electrical grounding applications?

- Indeed, electrical grounding applications can find steel sheets to be fitting. As a proficient conductor of electricity, steel can proficiently transmit electrical charges to the ground. Due to their endurance, robustness, and cost-efficiency, steel sheets are frequently employed in grounding applications. Their installation is simple, and they offer a trustworthy link to the earth, guaranteeing a secure pathway for electrical currents in the event of a fault or surge. Nevertheless, it is imperative to ensure the proper installation and upkeep of steel sheets, as any corrosion or harm can impede their conductivity and hinder their efficacy in grounding electrical systems.

- Q: What are the different sizes of steel sheets available?

- The different sizes of steel sheets available can vary depending on the specific manufacturer and supplier. Common sizes include 4x8 feet, 4x10 feet, and 5x10 feet, but there are also custom sizes available to meet specific project requirements.

- Q: How are steel sheets tested for quality?

- To ensure compliance with required standards, various methods are employed to test the quality of steel sheets. Among these methods, the tensile strength test is commonly used. This test gauges the steel sheet's ability to withstand stress before breaking, thus determining its durability and reliability in different applications. Another significant test is the hardness test, which measures the steel sheet's resistance to indentation or scratching. Specialized tools like Brinell or Rockwell hardness testers are utilized for this purpose. The hardness test aids in assessing the steel sheet's capacity to endure wear and tear, making it suitable for specific applications. The thickness of the steel sheet is also examined using a micrometer or ultrasonic thickness gauge to ensure it meets the necessary specifications. This is crucial as the thickness directly impacts the sheet's strength and ability to withstand external forces. Furthermore, visual inspection is carried out by trained professionals to identify any surface defects such as cracks, pits, or corrosion. Through meticulous examination, any irregularities compromising the steel sheet's quality can be detected. Chemical composition analysis is another pivotal test that determines the presence and proportion of various elements in the steel sheet. Spectrometry or X-ray fluorescence techniques are employed to ensure the steel sheet meets the desired chemical requirements. Moreover, steel sheets may undergo additional tests such as impact testing, bend testing, and fatigue testing to evaluate their performance under specific conditions. These tests replicate real-world scenarios and assess the steel sheet's ability to withstand anticipated loads and stresses. In conclusion, steel sheets are subjected to rigorous quality testing to meet the necessary standards and provide customers with reliable and durable products. These tests enable manufacturers to identify potential flaws or defects, allowing them to rectify any issues and deliver high-quality steel sheets to the market.

- Q: What are the different surface treatments for stainless steel sheets?

- Some of the different surface treatments for stainless steel sheets include brushed, mirror, satin, embossed, and etched finishes.

- Q: Can steel sheets be used for making furniture?

- Yes, steel sheets can be used for making furniture. Steel is a versatile material that offers several advantages when used for furniture construction. It is known for its strength, durability, and ability to withstand heavy loads. Steel sheets can be shaped, welded, and fabricated into various furniture pieces such as tables, chairs, cabinets, and even bed frames. Additionally, steel furniture tends to be resistant to rust and corrosion, making it suitable for both indoor and outdoor use. The sleek and modern aesthetic of steel also adds a contemporary touch to any space.

- Q: Are steel sheets suitable for medical equipment manufacturing?

- Yes, steel sheets are suitable for medical equipment manufacturing. Steel is a versatile and durable material that is commonly used in the production of medical equipment. It offers several advantages such as high strength, corrosion resistance, and ease of customization. Steel sheets can be easily formed, welded, and machined to create complex shapes and structures required for medical equipment. Additionally, steel is a hygienic material that can be easily cleaned and sterilized, making it suitable for use in healthcare settings. Overall, steel sheets are a reliable choice for manufacturing medical equipment due to their strength, durability, and ease of fabrication.

- Q: Can steel sheets be painted or powder-coated after installation?

- Yes, steel sheets can be painted or powder-coated after installation. Painting or powder-coating steel sheets after installation is a common practice to enhance their aesthetic appeal and provide additional protection against corrosion. The process involves thoroughly cleaning the steel surface, applying a primer to ensure good adhesion, and then applying the desired paint or powder coating. This can be done on-site or in a specialized facility, depending on the size and complexity of the steel sheets. Additionally, it is important to ensure that the chosen paint or powder coating is suitable for exterior use and can withstand the environmental conditions to which the steel sheets will be exposed.

- Q: Can steel sheets be used for manufacturing shipping containers?

- Yes, steel sheets can be used for manufacturing shipping containers. Steel is a durable and strong material that provides excellent structural integrity, making it ideal for constructing shipping containers. Steel sheets are typically used to create the walls, roof, and floor of the container, ensuring the container can withstand the rigors of transportation and protect the goods inside. Additionally, steel is resistant to various weather conditions, corrosion, and pests, making it a reliable choice for shipping container manufacturing.

- Q: What are hot and cold plates?

- Production process: in the production process without heating, so there is no pitting and iron oxide defects often appear in the hot rolling, good surface quality, high degree of finish. Moreover, the cold-rolled products have high dimensional accuracy, and the performance and organization of the products can meet some special requirements, such as electromagnetic properties and deep drawing properties.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. Steel is a strong and durable material that can provide a stable and secure base for solar panels. It has the necessary strength to support the weight of the panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to fit the specific requirements of the solar panel installation. Overall, using steel sheets for solar panel mounting can ensure a reliable and long-lasting foundation for the panels.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords