Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Thickness: 0.14-0.8mm

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Surface treatment: chromate, oil/unoil, bright finish, spangle,

Corrugated Sheet Materials: Galvanized steel, Aluzinc Steel, Aluzinc Pre-painted sheet and Aluminium sheet. Gloss: The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

Paint type: PE or PVDF

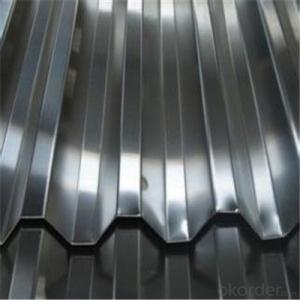

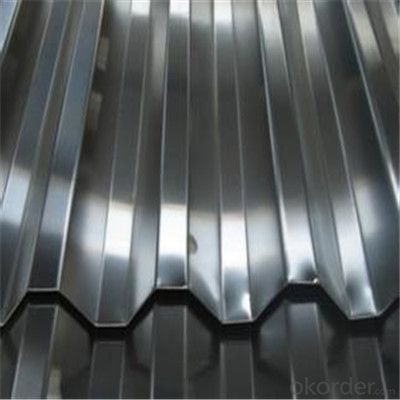

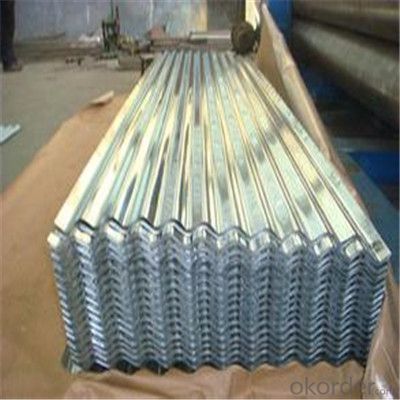

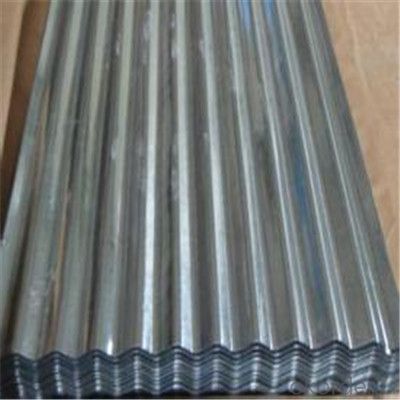

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for railway carriages?

- Yes, steel sheets are suitable for railway carriages. Steel is a popular material choice for railway carriages due to its strength, durability, and ability to withstand the constant wear and tear associated with train operations. Steel sheets provide the necessary structural integrity to support the carriage and its passengers, while also offering protection against impacts and extreme weather conditions. Additionally, steel is relatively cost-effective and readily available, making it an ideal choice for the construction of railway carriages.

- Q: What are the different packaging options for steel sheets?

- Some common packaging options for steel sheets include wooden crates, cardboard boxes, and metal skids. These packaging options provide protection during transportation and storage, ensuring that the steel sheets remain in good condition.

- Q: Do the steel sheets have any sharp edges?

- Indeed, sharp edges can be found on steel sheets. Throughout their production, steel sheets frequently undergo cutting or shearing processes, thereby resulting in the presence of sharp edges. It is of utmost importance to exercise caution when dealing with steel sheets and to employ suitable protective gear, like gloves, while working with them, in order to prevent any harm arising from the sharp edges.

- Q: Can steel sheets be used for manufacturing storage cabinets?

- Yes, steel sheets can be used for manufacturing storage cabinets. Steel is a durable and strong material that is commonly used in the construction of cabinets due to its ability to withstand heavy loads and provide long-lasting storage solutions. Additionally, steel sheets can be easily fabricated into various shapes and sizes, making them suitable for manufacturing cabinets of different dimensions.

- Q: Are steel sheets resistant to seismic activities?

- Yes, steel sheets are generally resistant to seismic activities due to their high tensile strength and ability to flex without breaking, which helps them withstand the powerful forces generated during earthquakes. Additionally, steel structures can be designed to incorporate specific seismic design principles, such as moment-resisting frames or base isolation systems, to further enhance their resistance to seismic activities.

- Q: Do steel sheets have any environmental benefits?

- Yes, steel sheets have several environmental benefits. Firstly, steel is highly recyclable, meaning that it can be reused multiple times without losing its strength or quality. This reduces the need for virgin raw materials and reduces the amount of waste being sent to landfills. Additionally, steel production has become more energy-efficient, resulting in lower greenhouse gas emissions compared to other materials. Steel sheets are also highly durable and resistant to corrosion, which means they have a longer lifespan and require less maintenance, reducing the overall environmental impact.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet is a steel sheet that has undergone the annealing process. This process includes heating the steel to a specific temperature and then cooling it slowly. By doing so, internal stresses in the steel are relieved and its ductility and workability are improved. Consequently, pre-annealed steel sheets possess greater formability and are more easily shaped and manipulated compared to their non-annealed counterparts. On the flip side, a full hard steel sheet has not been subjected to the annealing process and maintains its original hardness and strength. These sheets are commonly used in applications that necessitate high strength, durability, and resistance to deformation. They are less ductile and more rigid, which makes them suitable for situations where shape retention and stiffness are crucial, such as in automotive components or structural supports. In conclusion, the primary distinction between pre-annealed and full hard steel sheets lies in their formability and strength characteristics. Pre-annealed steel sheets are more malleable and easier to shape, while full hard steel sheets offer greater strength and rigidity. The choice between the two depends on the specific requirements of the application and the desired balance between formability and strength.

- Q: What is the average thickness of galvanized steel sheets?

- The specific application and industry standards can cause variations in the average thickness of galvanized steel sheets. Generally, galvanized steel sheets that are commonly accessible have a thickness ranging from approximately 0.4 millimeters to 3.175 millimeters. It is crucial to recognize that heavier galvanized steel sheets are frequently utilized for robust applications like construction and industrial purposes, whereas thinner sheets may be suitable for lighter applications such as automotive or household appliances. Furthermore, it is recommended to refer to the appropriate industry standards or manufacturers' specifications to determine the exact thickness requirements for specific applications.

- Q: What are the different types of steel sheet coatings?

- There are several different types of steel sheet coatings, including galvanized coatings, tin coatings, and polymer coatings.

- Q: Are steel sheets resistant to bullet penetration?

- Yes, steel sheets are generally resistant to bullet penetration due to their high hardness and toughness properties. However, the level of resistance can vary depending on the thickness and type of steel utilized, as well as the caliber and velocity of the bullet being fired.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords