Galvanized Corrugated Iron Sheet for Roofing Supplied in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

Corrugated board, also called pressure plate, with color coated steel, galvanized sheet metal plate by roll cold-formed into a variety of wave pressure plate, which is suitable for industrial and civil buildings, warehouse, special construction, large span steel house roof, walls and interior and exterior decoration. Has many characteristics such as light weight, high strength, rich luster, convenient construction, earthquake, fire prevention, waterproof, long service life, maintenance free, etc., has been widely applied.

Features of Corrugated Iron Sheet:

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

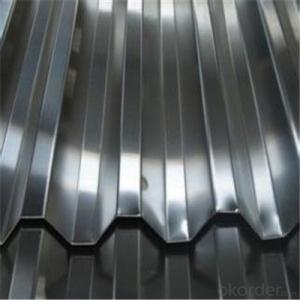

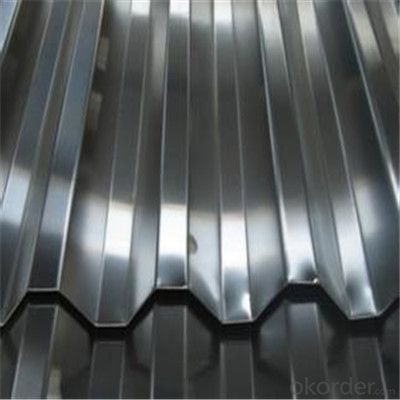

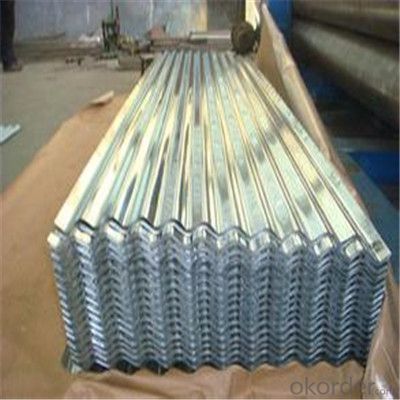

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used for fencing or security purposes?

- Yes, steel sheets can be used for fencing or security purposes. Steel sheets are durable and sturdy, making them an excellent material for constructing fences and barriers that provide enhanced security and protection. Their strength and resistance to wear and tear make them suitable for withstanding various external factors and potential intrusions. Additionally, steel sheets can be customized to fit different designs and sizes, ensuring they meet specific fencing or security requirements.

- Q: Why can iron and steel stick with glue?

- Iron and steel steel is an alloy of iron with C (carbon), Si (silicon), Mn (manganese), P (phosphorus), S (sulfur), and a small amount of other elements. In addition to Fe (iron), the content of C plays a major role in the mechanical properties of steel, so it is collectively referred to as iron carbon alloy. It is the most important and the most important and the largest metal material used in engineering.

- Q: Can steel sheets be used for signage purposes?

- Yes, steel sheets can be used for signage purposes. Steel is a durable and versatile material that can withstand various weather conditions, making it suitable for outdoor signs. Additionally, steel sheets can be easily cut, shaped, and painted to create custom signage designs.

- Q: Are the steel sheets suitable for automotive applications?

- Steel sheets are an excellent choice for automotive applications due to their exceptional strength, durability, and versatility. The automotive industry widely employs steel because of these qualities. It offers outstanding crash resistance, making it perfect for ensuring passenger safety in vehicle structures. Furthermore, steel sheets can easily be molded into intricate shapes, enabling the production of various automotive components like body panels, chassis, and frames. Steel also possesses excellent corrosion resistance, which is crucial for enduring harsh environmental conditions. In addition, it is cost-effective and readily accessible, making it a preferred option for automakers. All in all, steel sheets prove to be a dependable and fitting material for automotive applications.

- Q: What is the average thickness of steel sheets?

- The average thickness of steel sheets can vary depending on various factors such as the specific type of steel, its intended application, and industry standards. However, in general, steel sheets can range in thickness from around 0.4 millimeters (0.016 inches) to several millimeters (0.1 inches or more). It is important to note that different industries and applications may have specific requirements for steel sheet thickness, so it is always best to consult relevant standards or specifications for accurate information.

- Q: Can steel sheets be used for solar panel mounting structures?

- Yes, steel sheets can be used for solar panel mounting structures. Steel is a commonly used material for solar panel mounts due to its strength, durability, and ability to withstand various weather conditions. Steel sheets can provide a sturdy and reliable support system for solar panels, ensuring their stability and longevity.

- Q: What is the maximum width of steel sheets?

- The maximum width of steel sheets can vary depending on the manufacturing process and specific requirements, but it is typically around 2.5 meters or 8 feet.

- Q: Can steel sheets be used in high-temperature applications?

- Yes, steel sheets can be used in high-temperature applications due to their excellent heat resistance properties. Steel sheets are commonly used in industries such as automotive, aerospace, and manufacturing where high temperatures are encountered.

- Q: Can steel sheets be used for kitchen appliances?

- Yes, steel sheets can be used for kitchen appliances. Steel is a durable and versatile material that is commonly used in the manufacturing of various kitchen appliances such as refrigerators, ovens, and dishwashers. It offers excellent heat resistance, is easy to clean, and provides a sleek and modern look to the appliances.

- Q: What are the different edge finishes available for steel sheets?

- Depending on the desired aesthetic and functional requirements, steel sheets offer various edge finishes. The most common options are as follows: 1. Mill Edge: Directly from the steel mill, this is the standard and unfinished edge. It is typically used in non-critical applications like industrial or structural use. 2. Trimmed Edge: Irregularities and burrs are removed by trimming or shearing the rough mill edge. This provides a cleaner and more uniform edge, making it suitable for applications where appearance matters. 3. Deburred Edge: Through a deburring process, sharp or jagged edges are eliminated, resulting in a smooth and rounded edge. This enhances safety, making it common in applications involving frequent handling or contact. 4. Beveled Edge: The edge is cut or ground at an angle, creating a sloping or chamfered edge. This improves both aesthetics and functionality, especially in architectural applications and jointing or welding. 5. Rolled Edge: By rolling or bending the steel sheet's edge, a rounded or folded edge is formed. Rolled edges provide a smooth and finished appearance, making them ideal for visible applications like decorative or furniture manufacturing. 6. Hemmed Edge: Folding the edge of the steel sheet over itself creates a double-layered and durable edge resistant to fraying or unraveling. Hemmed edges are commonly used in exposed areas that require added durability, such as roofing or sign manufacturing. These examples demonstrate the range of edge finishes available for steel sheets. Each finish offers unique characteristics and benefits, allowing for customization based on specific requirements and preferences.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Supplied in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords