Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Iron Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

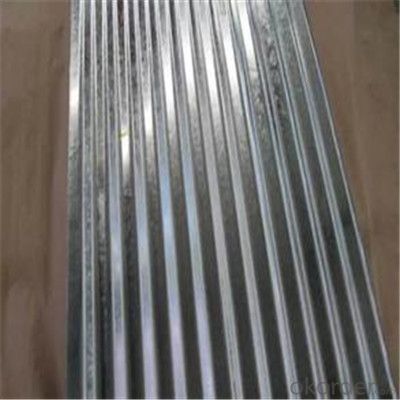

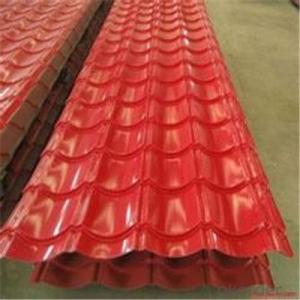

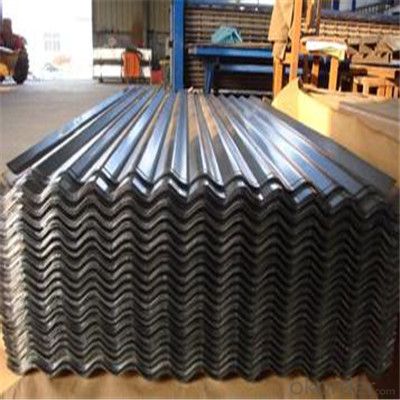

Description of Corrugated Iron Sheet:

1.Grade:SGCC, DX51D+Z, DX52D+Z, etc

2.Application:automotive, Strengthen plate, bearing

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Cold rolled steel coil-uncoil-Pickling-Annealed-hot dipped galvanizing-cooling -surface treatment -rolling -Cut the coil (galvanized steel sheet), demand your requirement. remark:Less than 5.8m ,20'container is ok,greater than5.8m,we must use 40'container

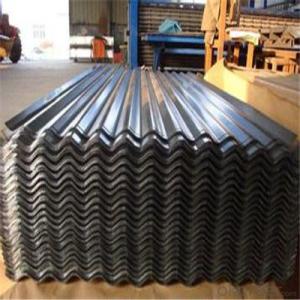

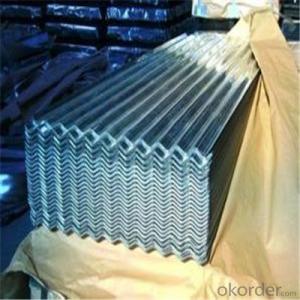

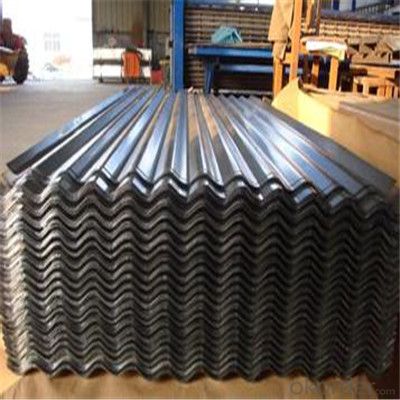

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used for transportation equipment?

- Certainly, transportation equipment can utilize steel sheets. The transportation industry extensively relies on steel due to its robustness, longevity, and cost-effectiveness. When it comes to constructing various transportation vehicles like cars, trucks, buses, trains, ships, and airplanes, steel sheets are frequently employed. These sheets find their application in the body panels, chassis, frames, and other fundamental components of these vehicles. Steel sheets possess remarkable mechanical attributes, including exceptional tensile strength and impact resistance, rendering them suitable for enduring the strains and requirements of transportation applications. Moreover, steel is renowned for its ease of formation and weldability, enabling manufacturers to fabricate intricate shapes and structures specifically needed for transportation equipment.

- Q: What is the standard size of a steel sheet?

- The standard size of a steel sheet can vary depending on the specific application and industry. However, in general, steel sheets are commonly available in standard sizes such as 4 feet by 8 feet (1.2 meters by 2.4 meters) or 5 feet by 10 feet (1.5 meters by 3 meters). These dimensions are widely used in construction, manufacturing, and fabrication processes. It is important to note that customized sizes can also be obtained based on the requirements of a particular project or customer.

- Q: Can steel sheets be used for manufacturing cutlery?

- No, steel sheets are not typically used for manufacturing cutlery. Cutlery is usually made from stainless steel, which is a specific type of steel that has excellent corrosion resistance and is easy to clean. Steel sheets, on the other hand, are generally used for structural applications such as construction, automotive, or manufacturing industries.

- Q: Can steel sheets be used for noise reduction purposes?

- Yes, steel sheets can be used for noise reduction purposes. Steel is a dense and rigid material that has good sound insulation properties. When properly installed as barriers or enclosures, steel sheets can effectively block and absorb sound waves, reducing noise levels in various applications including buildings, machinery, and vehicles.

- Q: Are steel sheets resistant to warping under heat?

- Yes, steel sheets are highly resistant to warping under heat. Steel has a high melting point and excellent thermal conductivity, which helps it maintain its structural integrity even at high temperatures. This makes steel sheets a suitable choice for applications where heat resistance is crucial, such as in construction, automotive, and industrial manufacturing.

- Q: Can steel sheets be used for automotive fuel tanks?

- No, steel sheets are not typically used for automotive fuel tanks due to their susceptibility to corrosion and weight compared to other materials like aluminum or plastic.

- Q: Can steel sheets be used in the telecommunications industry?

- Yes, steel sheets can be used in the telecommunications industry. Steel sheets are commonly used for various applications in the telecommunications industry due to their strength, durability, and ability to protect sensitive equipment. They are often used to manufacture communication towers, antenna mounts, equipment cabinets, and enclosures. Steel sheets provide structural support and can withstand harsh environmental conditions such as strong winds, extreme temperatures, and heavy loads. Additionally, steel sheets can be easily fabricated and customized to meet specific requirements, making them a popular choice in the telecommunications industry.

- Q: Can steel sheets be used for elevator manufacturing?

- Yes, steel sheets can be used for elevator manufacturing. Steel is a commonly used material in elevator construction due to its strength, durability, and resistance to fire and corrosion. Steel sheets are often used to fabricate the walls, floors, and doors of elevator cabins. Additionally, steel is also utilized for the structural framework and support components of the elevator system. The use of steel sheets in elevator manufacturing provides stability, safety, and longevity to the elevator, making it a reliable choice for vertical transportation.

- Q: Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications as they have good conductivity and can be easily shaped into desired forms for various electrical components.

- Q: Can the steel sheets be used for industrial machinery?

- Yes, steel sheets can be used for industrial machinery. Steel is a popular choice for the construction of industrial machinery due to its high strength, durability, and resistance to wear and tear. Steel sheets can be shaped, cut, and welded to create various components and parts required in industrial machinery. The versatility of steel allows manufacturers to design and fabricate machinery with precise specifications and requirements. Moreover, steel's ability to withstand heavy loads, extreme temperatures, and corrosive environments makes it suitable for use in a wide range of industrial applications.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Iron Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords