Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Standard: GB/T 12754-2006;ASTM A 755;EN 10169;JIS G 3312;AISI;BS;DIN Grade: SGCC,SGCH,G550,DX51D,DX52D,DX53D

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

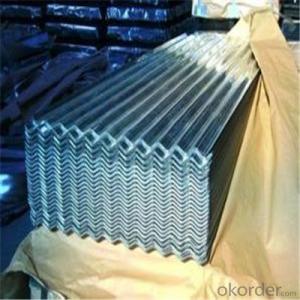

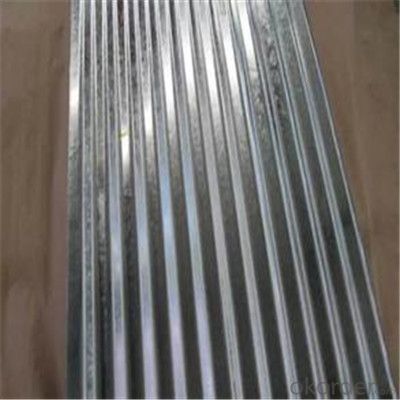

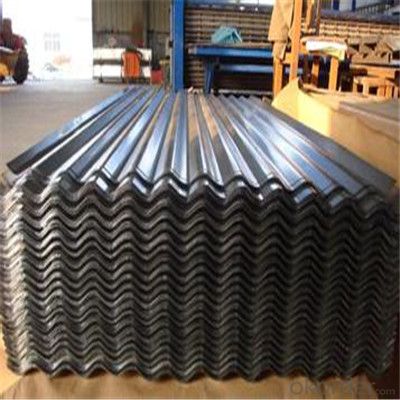

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used for electrical grounding?

- No, steel sheets cannot be used for electrical grounding.

- Q: What are the different shapes available for steel sheets?

- There are various shapes available for steel sheets, including but not limited to flat sheets, coils, strips, plates, and perforated sheets.

- Q: Can steel sheets be used for toolboxes?

- Yes, steel sheets can be used for toolboxes. Steel is a durable and strong material, making it suitable for toolboxes that need to withstand heavy use and provide protection for tools. Steel sheets can be formed and welded to create sturdy and long-lasting toolboxes.

- Q: Can steel sheets be used in HVAC systems?

- Yes, steel sheets can be used in HVAC systems. Steel is a commonly used material in HVAC systems for various components such as ductwork, air handling units, and heat exchangers. It is durable, strong, and can withstand high temperatures and pressures, making it suitable for HVAC applications.

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- The difference between hot rolled seamless steel tube and cold rolled seamless steel tube:1) cold-rolled seamless tubes tend to be of small diameter, and hot-rolled seamless tubes are often of large diameter.2) the accuracy of cold-rolled seamless steel tube is higher than that of hot-rolled seamless steel tube, and the price is higher than that of hot-rolled seamless steel tube.3) hot-rolled seamless tubes are divided into ordinary steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel tubes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes, etc..

- Q: Can steel sheets be used for food storage containers?

- No, steel sheets are not typically used for food storage containers as they can corrode and lead to contamination of the food. Food-grade materials like stainless steel or food-safe plastics are preferred for this purpose.

- Q: What are the different packaging options available for steel sheets?

- There are several packaging options available for steel sheets, including wooden crates, pallets, coils, and bundles. Wooden crates provide sturdy protection and are commonly used for transporting large steel sheets. Pallets are commonly used for smaller steel sheets and can be easily loaded and unloaded using a forklift. Coils are another option, where the steel sheet is wound into a coil shape for easier handling and transportation. Bundles involve securing multiple steel sheets together using metal bands or straps, providing a compact and secure packaging solution.

- Q: Can the steel sheets be easily cleaned?

- Yes, steel sheets can be easily cleaned.

- Q: What are the different alloying elements used in steel sheets?

- There are several alloying elements used in steel sheets to enhance their properties and performance. Some of the commonly used alloying elements include: 1. Carbon: The most important alloying element in steel, carbon provides strength and hardness to the material. It also improves the steel's ability to be heat-treated, making it suitable for various applications. 2. Manganese: Manganese is commonly added to steel sheets to improve their mechanical properties, such as strength and toughness. It also helps in reducing the brittleness of the steel. 3. Chromium: Chromium is added to steel sheets to enhance their corrosion resistance. It forms a thin protective layer on the surface of the steel, preventing it from rusting or corroding easily. 4. Nickel: Nickel is often used in steel sheets to improve their toughness and resistance to impact. It also enhances the steel's ability to withstand extreme temperatures, making it suitable for high-temperature applications. 5. Silicon: Silicon is commonly added to steel sheets to improve their strength and hardness. It also helps in deoxidizing the steel during the manufacturing process. 6. Vanadium: Vanadium is used as an alloying element in steel sheets to improve their strength, toughness, and heat resistance. It also helps in refining the grain structure of the steel, making it more uniform and fine. 7. Copper: Copper is added to steel sheets to improve their corrosion resistance and thermal conductivity. It also enhances the steel's ability to be welded and brazed. 8. Tungsten: Tungsten is used as an alloying element in steel sheets to improve their hardness, strength, and wear resistance. It is often added in small amounts to enhance the steel's cutting and drilling capabilities. These are just a few examples of the alloying elements commonly used in steel sheets. The choice of alloying elements depends on the specific requirements of the application and the desired properties of the steel. Different combinations and concentrations of these elements can be used to achieve a wide range of characteristics in steel sheets.

- Q: What are the different sheet metal joining techniques for steel sheets?

- There are several different sheet metal joining techniques for steel sheets, including welding, riveting, clinching, adhesive bonding, and mechanical fastening. Each method has its own advantages and limitations, and the choice of technique depends on factors such as the desired strength, aesthetics, and cost of the joint.

Send your message to us

Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords