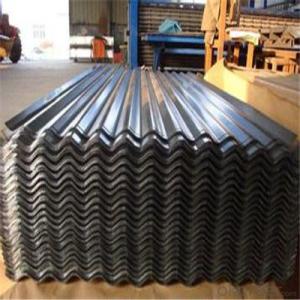

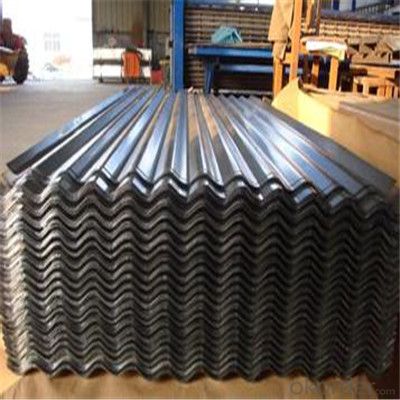

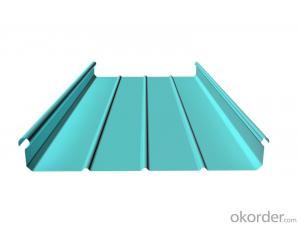

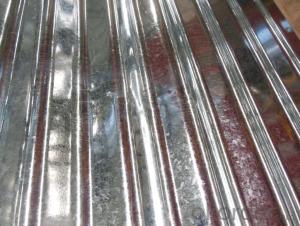

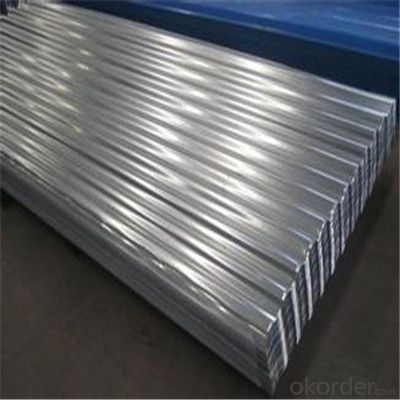

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

1.Grade:SGCC, DX51D+Z, DX52D+Z, etc

2.Application:automotive, Strengthen plate, bearing

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Long Lasting

Strong & Light Weight

Better Corrosion Resistance

Better Thermal Efficiency

Aesthetically Pleasing

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How do you calculate the yield strength of a steel sheet?

- The yield strength of a steel sheet can be calculated by dividing the maximum amount of stress that the sheet can withstand before it permanently deforms by the cross-sectional area of the sheet.

- Q: Are steel sheets suitable for automotive body parts?

- Yes, steel sheets are suitable for automotive body parts. They are commonly used in the automotive industry due to their high strength, durability, and excellent crash resistance. Steel sheets offer good formability and can be easily shaped into various car body components, providing structural integrity and safety to vehicles.

- Q: What is the electrical resistivity of steel sheets?

- The electrical resistivity of steel sheets typically ranges from 10^-6 to 10^-7 ohm-meters.

- Q: What are the weight considerations for steel sheets?

- Weight considerations for steel sheets vary depending on the specific application and desired outcomes. Here are a few important points to keep in mind: 1. Thickness: The weight of a steel sheet is greatly influenced by its thickness. Thicker sheets generally have more weight, while thinner sheets are lighter. It is important to select a thickness that meets the project's structural requirements while also considering weight limitations. 2. Strength requirements: Different applications call for steel sheets with varying levels of strength. High-strength sheets are often thicker and heavier, while lower strength sheets can be thinner and lighter. Understanding the strength requirements of the project is essential in determining the appropriate weight of the steel sheets. 3. Transportation and handling: The weight of steel sheets affects how easy they are to transport and handle. Heavier sheets require more labor and equipment for lifting, loading, and unloading. Additionally, transport vehicles have weight restrictions that must be taken into account when choosing sheet sizes. 4. Structural limitations: The weight of steel sheets can impact the overall structural design. In some cases, lighter sheets may be preferred to reduce the load on supporting structures. However, in other situations, heavier sheets may be necessary to provide the required strength and stability. 5. Cost considerations: The weight of steel sheets also affects the overall project cost. Heavier sheets generally cost more due to the increased material needed and additional handling expenses. Therefore, it is important to find a balance between weight, cost, and performance to optimize the project budget. In conclusion, weight considerations play a crucial role in determining the appropriate thickness, strength, transportation requirements, structural design, and cost-effectiveness of steel sheets for a project. By carefully evaluating these factors, one can select steel sheets that meet specific needs while ensuring the optimal weight for the desired outcome.

- Q: Can steel sheets be used for HVAC applications?

- Yes, steel sheets can be used for HVAC (Heating, Ventilation, and Air Conditioning) applications. Steel sheets are commonly used in the construction of HVAC ductwork due to their strength, durability, and fire resistance properties. They can be easily fabricated into various shapes and sizes to meet the specific requirements of HVAC systems. Additionally, steel sheets are resistant to corrosion, which is important in HVAC applications where moisture and condensation can occur. Overall, steel sheets are a suitable material choice for HVAC applications due to their mechanical properties and ability to withstand the rigors of heating, ventilation, and air conditioning systems.

- Q: How are steel sheets measured?

- Steel sheets are typically measured by their thickness, width, and length. The thickness is expressed in gauge or millimeters, while the width and length are measured in feet or meters.

- Q: Are the steel sheets easy to transport and handle?

- Yes, steel sheets are relatively easy to transport and handle. They are typically lightweight and can be easily stacked and loaded onto trucks or containers for transportation. Additionally, steel sheets often come in standardized sizes and shapes, making them easier to handle and maneuver. However, it is important to note that the size and thickness of the steel sheets can impact the ease of transportation and handling. Larger and thicker sheets may require specialized equipment or additional manpower to lift and move.

- Q: Can the steel sheets be used for metal stamping?

- Indeed, metal stamping can make use of steel sheets. Steel, renowned for its robustness and potency, is frequently employed as a material in metal stamping procedures. Generally, steel sheets are sliced into precise dimensions and shapes before being subjected to the stamping process, wherein a die and punch set are utilized to fashion the desired form onto the steel sheet. This technique enables the production of a diverse array of items, including automotive parts, household appliances, and industrial components.

- Q: How do steel sheets handle vibrations?

- Steel sheets are known for their excellent ability to handle vibrations. Due to their high stiffness and strength, steel sheets have the capacity to absorb and dampen vibrations effectively. This property makes them suitable for various applications where vibration control is crucial, such as in the construction of buildings, bridges, and machinery.

- Q: Are steel sheets suitable for elevator shafts?

- Indeed, elevator shafts can be suitably constructed using steel sheets. Steel, renowned for its robustness, endurance, and fire-resistant qualities, is extensively utilized in the construction sector. Considering the demands of elevator shafts, which necessitate a material capable of enduring substantial weights, maintaining structural integrity, and meeting safety regulations, steel sheets perfectly meet these prerequisites. Opting for steel sheets grants the flexibility to fabricate them into the desired dimensions and contours, facilitating creative design possibilities. Moreover, steel is effortlessly maintainable and repairable, guaranteeing the prolonged lifespan of the elevator shaft.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords