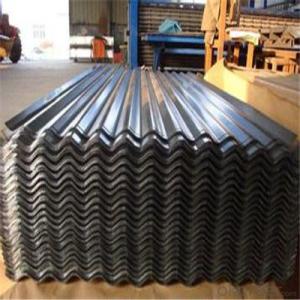

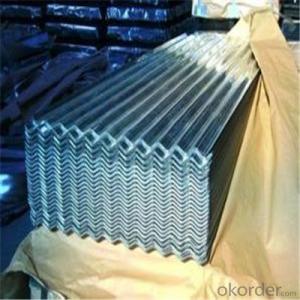

Galvanized Corrugated Steel for Roofings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:CUS-140527-K

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Surface Treatment:Galvanized

Technique:Cold Rolled

Thickness:0.12-1.5mm

Zinc Coating:40-275G/M2

Surface Structure:Ero Spangle, Regular Spangle or Normal Spangle

Width:600-1250mm

Material:SGCC,Sgcd,Secc,Secd,Dx51d+Z

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:ISO9001/SGS/BV

Origin:Henan, China

HS Code:7210

Production Capacity:300000 Mt/Year

Product Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy ,strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications,

Hot-dip aluzinc steel sheet is substrated on cold rolled steel (CRC) in various strength and specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

Specifications:

1. Thickness: 0.12-1.5mm

2. Width: 600-1250mm

3. Material: SGCC, SGCD, SECC, SECD, DX51D+Z

4. Zinc coating: 40-275G/M2

5. Surface Structure: Galvanized, zero spangle, regular spangle or normal spangle

6. Surface treatment: Chromated and oiled, chromated and non-oiled

Main characteristics:

1. Strong corrosion resistance

2. Surface quality

3. Conducive to deep processing, such as corrugated steel sheet 4. Economy and practicality

Packing

Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential, the contact points of these bands on the coil edge to be protect with edge protectors. Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. And each packed coil to be properly wrapped with band, three-six such band through the eye of coil at about equal distance, and two-four such bands securely tied around belly of coil at about equal distance.

| Commodity | Hot dip galvanized steel coil and sheet |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-1.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| delivery time | 25 days after recepit of 30% TT |

| Remarks | Insurance is as requirements |

| MTC will be handed on with shipping documents | |

| We accept the third party certification test |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and applications. However, commonly accepted standards for surface finish tolerance in the steel industry range between 10 to 20 microinches (0.25 to 0.5 micrometers).

- Q: what happened to all the steel beams from the WTC buildings? did anyone do any forensic analysisof any of the steel?

- some of the steel was recycled into a warship. I am not sure at what you are trying to get at with the forensic analysis of the steel. There is no conspiracy involving the towers outside of planes crashing into them despite what a lunatic fringe want you to think.

- Q: What are the different types of coil leveling machines?

- There are three main types of coil leveling machines: precision levelers, corrective levelers, and stretcher levelers.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a critical role in the manufacturing of pipes and tubes. They are the primary raw material used to produce these products. Steel coils are made by processing molten steel through a series of rolling mills, which shape the steel into flat, thin sheets. These sheets are then wound into coils for easy transportation and storage. In the manufacturing process of pipes and tubes, steel coils are unwound, and the flat sheets are passed through a series of machines and processes. The first step is usually to cut the steel sheets into the desired width and length. This is followed by forming the sheets into a cylindrical shape through a process called roll forming or continuous forming. The edges of the sheet are welded together to create a continuous pipe or tube. Steel coils provide several advantages in the manufacturing process. Firstly, they offer consistent and reliable quality. The production of coils ensures uniform thickness and strength throughout the entire length of the sheet, which translates to consistent properties in the final pipes and tubes. This is particularly important for applications that require high structural integrity and reliability. Secondly, steel coils allow for efficient production. The continuous supply of coils ensures a steady flow of raw material, reducing downtime and improving productivity. Coils also enable automated processes, such as roll forming, which can be highly efficient and cost-effective. Furthermore, steel coils offer flexibility in terms of size and dimensions. Coils can be produced in various widths and thicknesses, allowing manufacturers to customize the size and specifications of the pipes and tubes according to their specific requirements. This flexibility enables the production of pipes and tubes for a wide range of applications, from plumbing and construction to oil and gas pipelines. In conclusion, steel coils are the essential raw material in the manufacturing of pipes and tubes. They provide consistent quality, enable efficient production, and offer flexibility in size and dimensions. Without steel coils, the production of pipes and tubes would be significantly more challenging and less efficient.

- Q: How are steel coils used in the manufacturing of household appliances?

- Steel coils are used in the manufacturing of household appliances as they are shaped, cut, and formed into various parts such as panels, frames, and components. These coils provide strength, durability, and structural integrity to appliances like refrigerators, ovens, and washing machines, ensuring their stability and longevity.

- Q: how simple is it to take it scrape steel and recyle it. does annybody know the process . i want to do this but first i need some basic information. as far as i know first to melt the steel and in a furness on high heat and than give the shape that customer wants. how right or wrong am i . i want to start on a very small scale.

- Wow, Not sure there is a small scale.....Consider getting a truck,and picking up and collecting scrap metal.You can haul it to your local recycling center, get paid for it ..and let them do the melting and forging. Basics needed to know for this is: Separate Brass, copper, aluminum,cast iron (brake drums,rotors,old sinks and tubs) Car radiators are either copper or aluminum and they pay real well now. There is also a class called SHREDDER this is anything that is not in another category, and literally anything metal, Electrical motors pay good too.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as size, quality, and market conditions. It is best to contact a supplier or check current market prices to get an accurate cost.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils utilized in the creation of bridges can fluctuate depending on the precise requirements of the bridge undertaking. However, in general terms, the dimensions of steel coils used in bridge construction typically fall within the range of 0.5 to 1 inch in thickness and 36 to 72 inches in width. The length of the coils may also differ, but is commonly around 20 to 40 feet. These dimensions enable the production of various fundamental structural elements, such as beams, columns, and plates, which are indispensable for bridge construction. It is noteworthy that the dimensions may vary based on the specific design and engineering specifications of the bridge project, as well as the type and load capacity of the bridge being constructed.

- Q: How are steel coils used in the automotive industry?

- Steel coils are widely used in the automotive industry for various applications such as body panels, structural components, and engine parts. They are typically formed and shaped into desired forms through processes like stamping, bending, and welding. Steel coils provide strength, durability, and corrosion resistance to the vehicles, ensuring their safety and longevity.

- Q: days. Use your knowledge of the corrosion of steel and aluminum to predict how they would look different after a week exposed to rainy weather. Explain your prediction.

- Steel rusts, aluminum doesn't so the steel can would be rusty and the aluminum can would not.

Send your message to us

Galvanized Corrugated Steel for Roofings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords