Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dip Galvanized Steel Coil-Regular Spangle

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Product Description Of Hot Dip Galvanized Steel Coil-Regular Spangle

|

Thickness |

0.13mm-0.7mm |

|

Width |

600mm-1250mm |

|

Zinc Coating |

30-200g/m2 |

|

Internal Diameter |

508mm/610mm |

|

Coil Weight |

3-12MT |

|

Quality |

commercial and structural quality |

|

Surface Treatment |

regular & minimum spangle, zero spangle, oiled & dry, chromated , non-skin pass , skin pass |

|

Standard |

JIS G 3302, ASTM A 653M, EN 10327 |

|

Steel Grade |

SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Technical Data Of Hot Dip Galvanized Steel Coil-Regular Spangle

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Hot Dip Galvanized Steel Coil-Regular Spangle

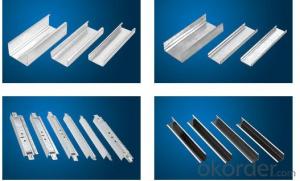

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Packaging & Delivery Of Hot Dip Galvanized Steel Coil-Regular Spangle

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Hot Dip Galvanized Steel Coil-Regular Spangle

Production flow of hot dip galvanized steel coil - zero spangle - forward - 30 - 200g/m2 include dual uncoiler, stitcher(welder), bridle, steering unit, entry accumulator, heating & soaking furnace, jet cooling section, ceramic zinc port, cooling tower, skin pass mill, tension leveller, chromating with dryer, exit accumulator and dual recoiler.

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they are typically shaped and cut into various components such as blades, springs, and handles. These coils provide the necessary strength and durability required for the tools and equipment to withstand heavy usage and perform effectively.

- Q: I want to know because I'm going to Hershey Park on Wednesday and Steel Force looks about the same size, so, I wanted to know. It's not that Steel Force is too big for me.

- steel force breaks the 200ft mark and is a steel out and back roller coaster. Tidal force is a water ride that is about 100 ft tall. If you can do Steel Force then you should be able to handle anything at Hersheypark. the on;y ride they have bigger is the Kissing Tower

- Q: What are the common coil finishes available for steel coils?

- Steel coils can be finished in various ways to serve different purposes and achieve different aesthetic appearances. Some popular coil finishes include: 1. Hot-dip galvanized: By immersing the steel coil in molten zinc, a protective layer is formed on its surface. This finish is ideal for outdoor applications like roofing, fencing, and automotive parts due to its excellent corrosion resistance. 2. Galvannealed: Achieved by annealing the hot-dip galvanized coil, this finish gives a matte gray appearance. Galvannealed coils have enhanced paint adhesion, making them suitable for subsequent painting or powder coating in applications like appliances and furniture. 3. Electro-galvanized: A thin layer of zinc is electroplated onto the surface of the steel coil in this process. Electro-galvanized finishes offer good corrosion resistance and are commonly used indoors, such as in electrical enclosures, HVAC systems, and automotive components. 4. Pre-painted or coated: These finishes involve applying a layer of paint or a coating system to the steel coil, improving its appearance and providing extra protection. Pre-painted coils are extensively used in construction, appliances, and automotive industries due to their aesthetic appeal and corrosion resistance. 5. Bare or mill finish: This refers to the untreated, raw steel coil without any additional coatings or finishes. Bare steel coils are commonly used in applications where corrosion resistance is not the main concern, such as structural components, pipes, and tubes. These are just a few examples of the many coil finishes available for steel coils, each offering unique properties and advantages depending on the intended use. Carefully considering the specific requirements of the application is important when choosing the most suitable coil finish.

- Q: What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils range from 0.15mm to 25mm, depending on the specific requirements and applications.

- Q: Can steel coils be used in architectural applications?

- Architectural applications can indeed utilize steel coils. These coils possess versatility and can be transformed into various shapes and forms to match the distinctive design specifications of architectural ventures. They find utility in constructing structures such as buildings, bridges, and more, as well as in fabricating architectural elements like roofing, cladding, and facades. The utilization of steel coils in architectural applications presents several benefits. They exhibit exceptional durability, strength, and corrosion resistance, rendering them suitable for constructing enduring and low-maintenance structures. Steel coils can be customized in terms of thickness, width, and surface finish, granting architects the ability to achieve their desired aesthetic and functional objectives. Moreover, steel coils are renowned for their structural stability and load-bearing capacity, both of which are vital considerations in architectural designs. Their high strength-to-weight ratio makes them an ideal selection for creating spacious and open interior areas, as well as for supporting heavy loads in multi-story buildings. Additionally, steel coils are easily fabricated and installed, resulting in time and labor savings during the construction process. They can be efficiently molded, cut, and welded to create intricate shapes or architectural details. Additionally, steel coils can be pre-fabricated off-site, guaranteeing precision and quality control, and subsequently assembled on-site, reducing construction time and minimizing disruptions to the surrounding environment. All in all, steel coils present architects and designers with a wide array of possibilities in architectural applications. Whether it pertains to structural support, aesthetic appeal, or functional requirements, steel coils provide a dependable and versatile material option that can fulfill the demands of contemporary architectural projects.

- Q: What are the common coil lengths available for steel coils?

- The common coil lengths available for steel coils vary, but typically range from 5,000 to 15,000 feet.

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems as they are an essential raw material for manufacturing various components, such as chassis, frames, body panels, and suspension systems. These coils are shaped, cut, and welded to create the structural framework and body of vehicles, ensuring strength, durability, and safety. Additionally, steel coils are also used in the production of railway tracks and infrastructure, further supporting the transportation sector.

- Q: How do you prevent damage to steel coils during transportation?

- To prevent damage during the transportation of steel coils, there are several measures that can be taken: 1. Tight and secure packaging: It is important to pack the steel coils tightly and securely to prevent any movement or shifting during transportation. This can be achieved by using appropriate packaging materials such as steel cradles, wooden dunnage, or steel straps to hold the coils in place. 2. Use cushioning materials: Adding cushioning materials like foam padding, cardboard, or bubble wrap between the coils can help absorb shocks and vibrations during transit. This additional layer of protection minimizes the risk of scratches, dents, or other damages caused by contact with other objects or surfaces. 3. Handle and load properly: It is crucial to use proper lifting equipment and techniques to avoid mishandling and dropping of the steel coils. Carefully lifting and loading the coils onto transportation vehicles using forklifts or cranes is recommended. Additionally, stacking the coils in a way that distributes weight evenly helps maintain stability. 4. Protect from weather: Steel coils are susceptible to corrosion, so it is essential to shield them from moisture and adverse weather conditions during transportation. Covering the coils with waterproof and weather-resistant tarps or shrink wrap prevents water or moisture from reaching the steel surfaces. 5. Regular inspections: Conducting regular inspections before, during, and after transportation is vital to identify any potential damage or issues. This allows for timely intervention to rectify any problems and prevent further damage. 6. Trained personnel: It is crucial to ensure that personnel involved in handling, loading, and transporting the steel coils are properly trained. They should be knowledgeable about the correct procedures and techniques to safely handle and transport the coils, reducing the risk of damage. By implementing these preventive measures, the likelihood of damage to steel coils during transportation can be significantly reduced, ensuring that the coils reach their destination in optimal condition.

- Q: Are steel coils affected by temperature changes?

- Yes, steel coils are affected by temperature changes. Steel is a metallic material that expands when heated and contracts when cooled. Temperature fluctuations can cause steel coils to expand or contract, which may impact their dimensions, mechanical properties, and overall performance. It is important to consider and manage temperature changes to ensure the proper functioning and durability of steel coils.

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 33.03% Southeast Asia 33.03% South America 20.18% Africa 13.76% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port, China |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 100 People |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords