Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

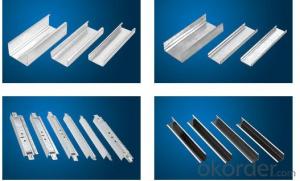

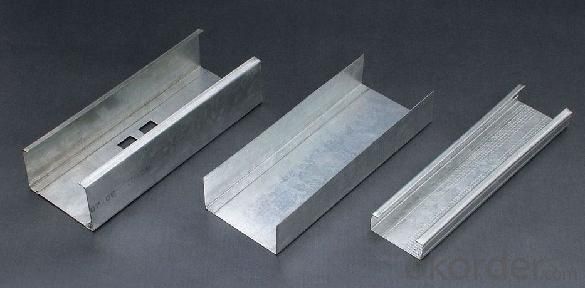

Drywall studs and tracks

Metal studs and tracks

Galvanized steel c profiles

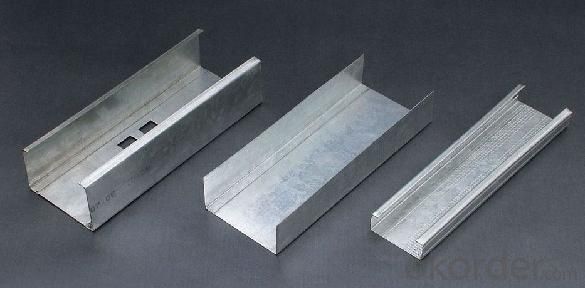

Hot dipped zinc galvanized.

Surface regular spangle

Easy to fix up

All kinds of types

Good rust-Proof function

Drywall Stud & Track and Furring Channel /c channel metal stud

Drywall Stud and Channel, for Ceiling Suspension and Partition Wall System.

Drywall Stud and Channel

Metal Profile, Drywall Stud and Track

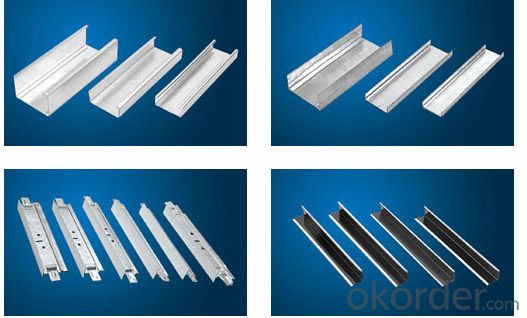

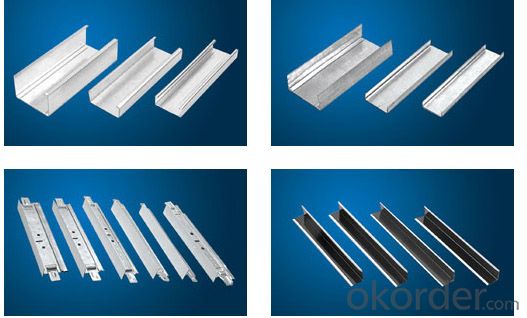

Regular Specification for Ceiling Suspension System:

DU38 38*12*3000/6000*0.8 / 1.0mm

DU50 50*15*3000/6000*1.0 / 1.2mm

DU60 60*27*3000/6000*1.2mm

DC50 50*15*3000/6000*0.38 / 0.45mm

50*19*3000/6000*0.38 / 0.45 / 0.5mm

DC60 60*27*3000/6000*0.6mm

Regular Specification for Partition Wall System:

QC75 75*35*3000/6000*0.5/ 0.6 / 0.7mm

75*40*3000/6000*0.6mm

75*45*3000/6000*0.6 / 0.7mm

75*50*3000/6000*0.6mm

QC100 100*45*3000/6000*0.7mm

100*50*3000/6000*0.7mm

QU75 75*35*3000/6000*0.5 / 0.6 / 0.7mm

75*40*3000*6000*0.6mm

QU100 100*35*3000/6000*0.7mm

100*40*3000/6000*0.7mm

Application

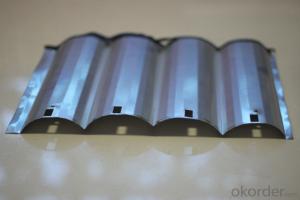

1. used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: What are the different types of edge treatments for steel coils?

- There are several different types of edge treatments for steel coils, each serving a specific purpose and providing different benefits. 1. Slit Edge: Slit edge is the most common type of edge treatment for steel coils. It is achieved by cutting the coil along its width, resulting in two distinct edges. Slit edges are generally smooth and free from burrs, making them suitable for most applications. 2. Mill Edge: Mill edge is the untreated edge of a steel coil as it comes from the rolling mill. It is characterized by a rough and uneven surface, with visible imperfections such as burrs and irregularities. Mill edges are typically not suitable for direct use and require further processing or trimming to achieve a desired edge quality. 3. Trimmed Edge: Trimmed edge is an edge treatment that involves removing the rough and irregular portions of the mill edge. This process is done through shearing or cutting, resulting in a smoother and more consistent edge. Trimmed edges are commonly used when a clean and uniform appearance is required. 4. Deburred Edge: Deburring is a process that removes any sharp or rough edges from the steel coil. This treatment is essential for applications where safety is a concern, as it eliminates the risk of injury from handling sharp edges. Deburred edges are achieved through grinding or filing and provide a smooth and safe edge for various applications. 5. Rounded Edge: Rounded edge is a type of edge treatment that involves rounding the sharp corners of the steel coil. This treatment is often used to prevent damage to other materials or surfaces during handling or transportation. Rounded edges reduce the risk of scratches, dents, or other forms of surface damage. 6. Beveled Edge: Beveled edge is an edge treatment where the edge of the steel coil is cut at an angle, typically 45 degrees. This type of treatment is commonly used in applications that require a tight fit or seamless joint with other components. Beveled edges allow for easier assembly and improve the overall appearance of the final product. Each of these edge treatments has its own advantages and is chosen based on the specific requirements of the application. The selection of an appropriate edge treatment for steel coils is crucial to ensure optimal performance, safety, and aesthetics in various industries such as construction, manufacturing, automotive, and more.

- Q: What are the common methods of packaging steel coils for international shipping?

- Various techniques are employed to package steel coils for international shipment in order to guarantee their safety and security during transit. One approach involves the utilization of wooden crates. Steel coils are positioned on wooden pallets and fastened with steel bands or straps. Next, wooden boards or plywood are placed over the coils and firmly attached with nails or screws to create a robust crate. This method ensures exceptional protection against damage and guarantees that the coils remain fixed in place during transportation. Another option is to employ steel frames or skids. Steel coils are positioned on specially designed steel skids or frames that can support the weight and shape of the coils. These coils are then secured to the skids or frames using steel bands or straps. This method offers a high level of stability and protection, making it particularly suitable for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specifically designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the chosen packaging method, it is crucial to ensure that the steel coils are adequately shielded from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. In summary, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. The selection of these methods depends on factors such as the size, weight, and specific requirements of the coils, with the ultimate goal of providing maximum protection and security during transit.

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- Coat it in molten plastic, or use stainlessteel

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel Rod Tompkins Steel Blaze Tompkins Steel Adam Tompkins

- Q: How are steel coils protected from chemical damage?

- Steel coils are protected from chemical damage through various methods such as applying protective coatings, using corrosion inhibitors, and storing them in controlled environments to minimize exposure to harmful chemicals.

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are an essential component in the production of metal buildings as they are used to create the structural framework and outer cladding. These coils are unrolled and cut into sheets, which are then shaped and formed into various building components such as beams, columns, and panels. The strength and durability of steel make it an ideal material for constructing metal buildings, ensuring they are capable of withstanding harsh weather conditions and providing long-lasting structures.

- Q: Explain why a steel nail sinks but a steel ship floats.

- surface area of the ship against the water is much greater than the nail.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- guage means thickness.

- Q: nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- Nylon Strings For Acoustic Guitar

Send your message to us

Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords