Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-dip Galvanized Steel Description:

Hot-dip Galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process.Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of Hot-dip Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

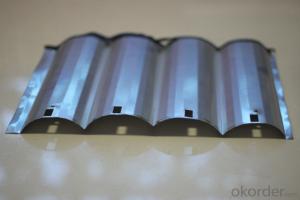

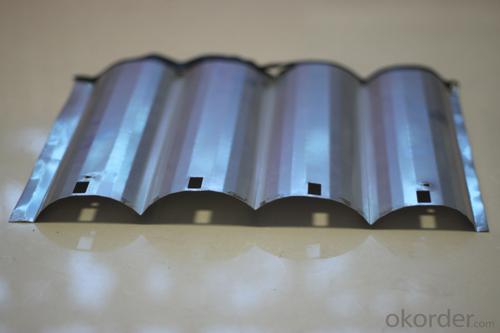

3. Hot-dip Galvanized Steel Images

4.Hot-dip Galvanized Steel Specification

Standard: ASTM A653M,EN10327,JIS G 3302

Grade: CS, DX51D+Z,SGCC

Thickness: 0.15mm~3.5mm

Width: 1250,600-1250mm

Coil weight:3-10 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Hot-dip Galvanized Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Is the polyurethane sandwich panel and foam board flame retardant?

- To see if there is no added flame retardant

- Q: V950 color steel rock wool sandwich panel and v960 color steel rock wool sandwich board what does it mean

- Is the practical width of the tile of 950 watts a meter long is 0.95 level 960 is 0.96 level

- Q: What is the difference between handmade rock wool sandwich panels and mechanism sandwich panels?

- As the name suggests, the inner layer is a foam board, thermal insulation but not set fire. The other is rock wool, thermal insulation, fire!

- Q: How about the sound insulation of the sandwich panel?

- Insulation material does not have the same frequency of noise barrier effect is not the same, impermeable to prevent the snow from the inside into the Caigang sandwich panels. Snow is important to pass through the gap or node into the color steel sandwich panels. To achieve the performance of anti-seepage, the need to use the sealing ring in the screw seal after the adoption of hiding-type flow, the overlap in the board with a sealant or riveting solution. Because of the variety of metal sheet roofing, color steel sandwich panels from heavy public buildings to the plant, Caigang sandwich panels sound insulation to a sound insulation coefficient a. 8% annual increase in the progress of Caigang sandwich panels after the installation of the roof without access to the mouth, steel structure with energy saving, environmentally friendly recyclable, Caigang sandwich board confidence that few people can see on the spot.

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: What are the advantages of polyurethane gluing wool sandwich panels?

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: What is the latest export tax rebate rate for sandwich panels and color steel tiles? Thank you

- 3921199000 Other foam sheets, sheets, films, foils, strips Tax rebate rate 13% No regulatory conditions 7210700000 painted or coated iron or non-alloy steel wide sheet (width ≥ 600mm) Tax rebate rate 13% No regulatory conditions

- Q: Use the foam color steel sandwich panel after decoration

- Paste the gypsum board with a gauze plate on the sandwich panel. The seams of the gypsum board may be properly reinforced with self-tapping screws to prevent cracking at the joints. Then, in accordance with the normal order of operation to wear bandages, approved scraping putty, polished, and finally brush on the latex paint on the line, the effect of the same with the ordinary wall.

- Q: Color steel sandwich panel has what color?

- Highland and white ashes. Special colors can be customized

- Q: 7 meters span steel structure color steel sandwich panels roof, column, truss, purlins, respectively how much? What is the column spacing?

- Steel frame with No. 20 H steel, purlins C160, open to 4 meters or 6 meters, to reduce material loss.

Send your message to us

Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords