WBP Melamine Glue Poplar Core Film Faced Plywood with 19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Brand Name: buildplex

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Plywood Type: Other

· Size: 1220x2440mm,1250x2500mm

· Thickness: 18mm,9mm 12mm, 15mm,21mm

· Core: poplar

· Glue: WBP

· Cycle life: 2-4 times uses

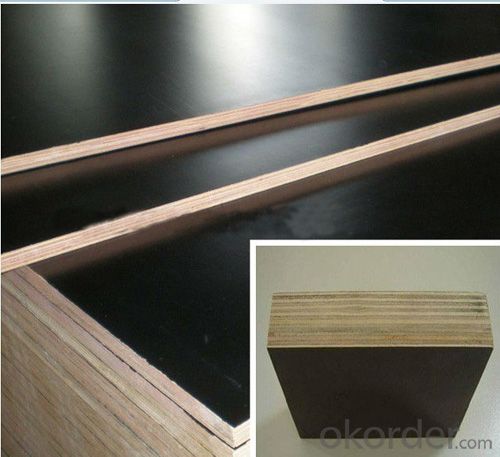

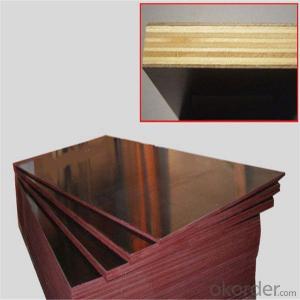

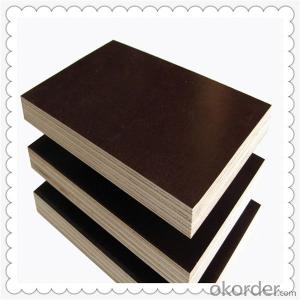

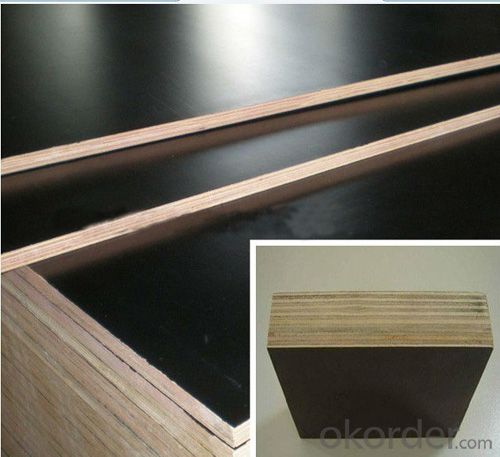

· Film: brown,black,red

· Moisture: below 16%

Packaging & Delivery:

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

Delivery Detail: | within 20 days after receiving LC or deposit |

Product Specification:

Product Name | Film faced plywood |

F/B | Black film, brown film, red film |

Grade | First grade |

Core | poplar |

Glue | WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 20 days after order confirmed |

Supply Capacity | 5000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique Credit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result | |

1 | Moisture content | % | EN322 | 10 | Check out | |

2 | Density | Kg/m3 | EN322 | 530 | Check out | |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.27 Min:0.6 | Check out |

Damage rate | % | GB/T17656-1999 | 60% | |||

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 5800 | Check out |

Lateral | 4500 | |||||

5 | Bending strength(N/mm) | Longitudinal | 40.1 | Check out | ||

Lateral | 33.2 | |||||

6 | Cycle Life | About 2-4 repeated using times according projects by formwork application | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Is the polyurethane sandwich panel and foam board flame retardant?

- On the market, the polyurethane foam flame retardant grade B1, B2, B3 three grades. Because of the cost, sandwich board with the majority of polyurethane material is B3 level, a small amount of B2 level, there are a small amount of special requirements B1 level. B1 level for the 'flame'; B2 level for the 'combustible'; B3 level for the 'flammable'. B1 grade oxygen index requirements of more than 30%; B2 level requirements of more than 26%, 26% of the following collectively referred to as B3 level. You said the flame retardant, it should be self-extinguishing from the fire. B2, B1 from the heat certainly no problem. A little better B3 (oxygen index of about 25%) can also be self-extinguishing, but more than B2 self-extinguishing time more than a few seconds. General oxygen index of less than 24%, it is difficult to self-extinguishing from the fire, will always burn, the greater the greater the burning. The The Oxygen Index: The concentration of oxygen required to stabilize the combustion in the oxygen and nitrogen gas mixture under the specified shape of the foam, the specified source of fire and the size of the flame. - For example, the better the flame retardant properties of the foam, the higher the concentration of oxygen needed to ignite the foam, the higher the oxygen index of the bubble

- Q: Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Yes, EPS is glass steel surface, color steel sandwich board is color steel surface, EPS expensive, the difference is about 100 per meter

- Q: V950 color steel rock wool sandwich panel and v960 color steel rock wool sandwich board what does it mean

- Is the practical width of the tile of 950 watts a meter long is 0.95 level 960 is 0.96 level

- Q: Plan to use Caigang sandwich panels to do the roof. The wall is brick wall. Ask how the sandwich panel is fixed on the brick wall ah?

- Wall to do reinforced concrete ring beam cap, and then fixed on the ring beam C-keel, sandwich plate fixed on the keel, complete.

- Q: Color steel sandwich board where the best quality?

- To see where you are, too far away from the good cost is also high, the best distance from the nearest, I was Xuzhou people, I think before the company in the Pepsi Steel made Bo Sige plate is very good,

- Q: How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

- Q: What is the polyurethane sandwich board material

- Double-sided color steel, the middle of the polyurethane sandwich composite panels Generally used in the roof of the building roof, the board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety. Upper and lower board plus the common role of polyurethane, with high strength and stiffness, the lower plate smooth and smooth, clear lines, increase indoor aesthetics, flatness. Easy installation, short duration, beautiful, is a new type of building materials.

- Q: Will the rock wool sandwich board which manufacturers better?

- OKorder Zhongji Machinery Manufacturing Co., Ltd. R & D and production of rock wool polyurethane sandwich panel equipment, rock wool / EPS color steel sandwich panel equipment can produce a variety of different types of fire insulation sheet. Won the title of state-level high-tech enterprises, and the Ministry of Commerce was identified as designated equipment export manufacturers. After-sales service is good, but it is expensive point Oh

- Q: Color steel polystyrene sandwich panel specifications 0.4 * 0.3 * 50mm, of which 0.3,0.4,50 size, respectively, where the size

- Do not know what you say 0.3,0.4 unit of measurement is rice or centimeters. If it is followed by the 50 mm unit that is consistent, it basically can not say it! However, on this color steel to understand the words, 50 mm refers to the thickness. 0.4,0.3 units should be meters, so that should be 0.4 meters long, 0.3 meters wide, 0.05 meters thick polystyrene board.

Send your message to us

WBP Melamine Glue Poplar Core Film Faced Plywood with 19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords