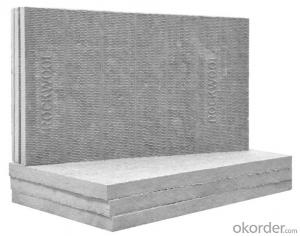

Rock wool sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sandwich Panel definition

Sandwich panels for building applications are large prefabricated building products.

Sandwich panels generally consist of two outer metal sheets (steel, aluminium, other) with a stabilizing core of insulation sandwiched between them. The metal sheets are bonded to the insulation core with specialised adhesives. The outer surface of the sheets can be flat, slightly corrugated or with a significant profile (eg. for roofs or external façade design). A huge assortment of shapes, coatings and colours is available. Because sandwich panel installation requires only a limited number of mechanical fasteners (eg. screws), the resulting constructions avoid significant thermal bridging. To achieve distinctive architectural features, panels with hidden joints are available.

Since 2009 a new European standard EN 14509 has defined the regulation and quality of sandwich panels with insulating core materials.

At ROCKWOOL our sandwich panel specialists are trained to support sandwich panel producers and other component suppliers to achieve maximum panel performance. For many years ROCKWOOL has developed and supplied robust insulation core materials for sandwich panel solutions worldwide

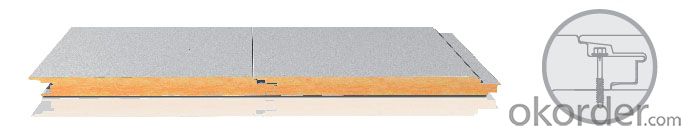

Rock wool composite wall panel system (vertical) -- MQ1-T-W

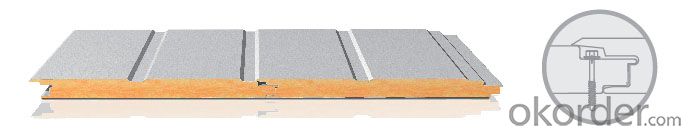

Rock wool composite wall panel system (horizontal) -- MQ2-T-W

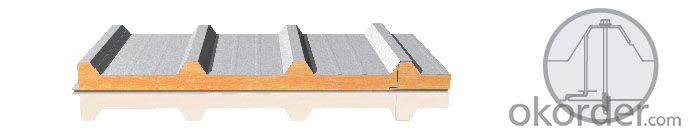

Rock wool composite wall panel system (horizontal) -- MQ3-T-W

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=600mm-1000mm

Rock wool composite roof system -- MW1-T-W

Xinxin's rock wool sandwich panle with two layers of color steel bonded and a high density rock wool fire proofing, insulation core material formed in the middle as a whole, can be widely used in a fire, sound and heat insulation requirements of public, business and indestrial constrction.

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=1000mm

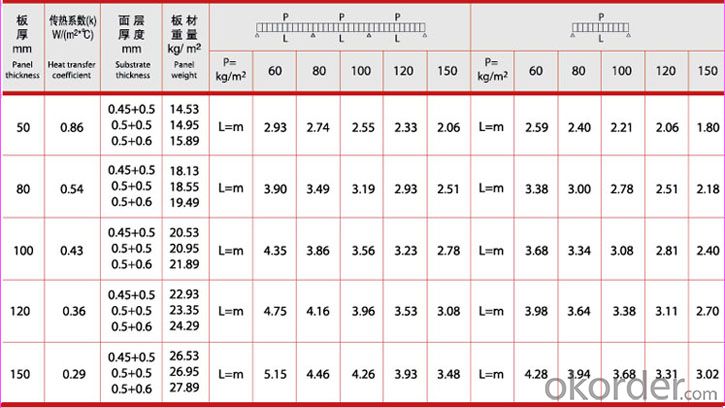

Metal surface rock wool sandwich panel design specifications

1.Wall plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/240)

Core density = 120 kg/m3

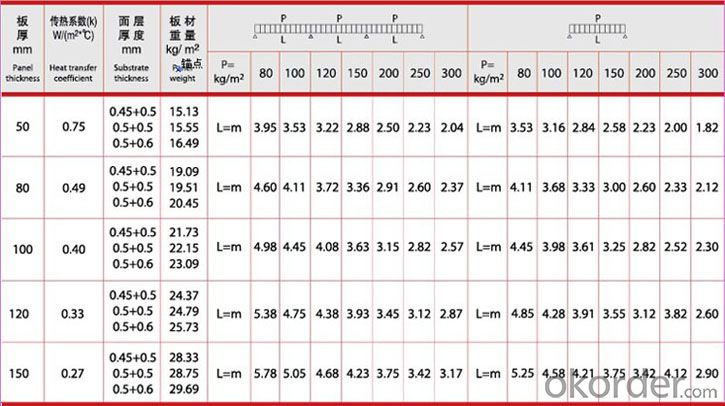

2.Roof plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/200)

Core density = 120 kg/m3

- Q: Color steel sandwich panel foam per cubic meter of weight is how much

- The national standard is 18kg. Color steel sandwich panels are common in the current building materials, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor.

- Q: Why do you want to use polyurethane seal on both sides of the multi-dimensional joint group of OKorder Yanmian sandwich panels

- As a new type of rock wool sandwich panels, his plate is a dark buckle is not nails, so that the board on both sides of the plug interface into the opposite sex, and in the production process sent by the rock wool is equal thickness, which makes The mouth and the mouth of the mouth of the cotton-free cavity, and the subsequent manual joints, but also produce cotton and steel plate bonding performance is poor, anti-stripping poor, this result will be cold in the winter, summer will produce heat Bridge, the more serious is in the wall board, bear the load object entirely by the self-tapping to bear, and because the rock wool sandwich panel is horizontal installation, and its two sides of the plug interface becomes the upper and lower parts, and its Is empty, so that the rock wool is completely attached to the steel by glue, a long time, rock wool fall, resulting in deformation

- Q: Blockboard (sandwich panel) decoration cabinet right?

- The cabinet can be used with blockboard, blockboard grip screw force, high strength, with quality Kennedy, sound absorption, insulation and other characteristics, and moisture content is not high, between 10% -13%, easy processing, the most use widely. Blockboard than solid wood sheet stability, but fear of wet, construction should be avoided to avoid the kitchen. Uses: furniture, doors and windows and sets, partition, false walls, heating hood, curtains and so on.

- Q: Use the sandwich board to do the quotation of the wall how to do ah

- The board of the board is made of lightweight Polish special cement, EPS granule, expanded perlite, a variety of high-molecular light aggregate for core board, strong composite treatment made of lightweight partition plate

- Q: How to install the wall rock wool sandwich panels

- 1, handling the plate should also be lifted at both ends, so as not to damage the appearance of oxide film or coating. When installing the wall panel, only one board can be lifted at one time. It should be used for the special fixture supplied by the manufacturer of the rock wool sandwich panel. Lifting process to slow down, to use the wind rope to be controlled to prevent the wall with the device has been bump, scaffolding raised parts with soft data package. 2, sandwich plate fixation method: one is the self-tapping screw through the wall directly to the wall in the secondary structure. Another method is the self-tapping screw connected directly to the wall sub-structure via the coupling.

- Q: Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Is the foam sandwich panel soundproof?

- In terms of sound insulation, the foam board is very good, but if there is a wire recommended not to use foam board, because the wire with a long time will be hot, it is easy to fire. It is recommended to use gypsum board, double, hollow, up and down with a glass gel seal, so that better play a sound insulation effect, if you want a better sound insulation, gypsum board can be replaced by soundproof glass wall, that no matter what noise or what are Solved, is the cost of some more expensive. If you want to block the line of sight can be single-sided glass on the things that ok

- Q: Color steel sandwich panel can do the widest, can be more than rice

- Can be a maximum of 1.1 meters

- Q: What are the requirements for the use of foam sandwich panels for fireworks

- Roof absolutely do not use, the wall can discuss to reach the fire rating

Send your message to us

Rock wool sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords