Sandwich Panels India

Sandwich Panels India Related Searches

Sandwich Panels Nz Sandwich Panel System Sandwich Panel Accessories Sandwich Panel Thailand Sandwich Panel Manufacturers Uae Sandwich Panel Manufacturers In Bangladesh Sandwich Panel Structure Sandwich Panel Philippines Structural Insulated Panels India Sandwich Panel Cyprus Sandwich Panel Turkey Sandwich Panel Kuwait Aluminium Honeycomb Sandwich Panel Cieling Panels Curved Polycarbonate Panels Curtain Panels Structural Insulated Panels Lightweight Structural Panels Ranilla Panels Structural Insulated Panels Australia Large Plastic Panels Insulated Panels Philippines Polyurethane Panels Australia Clear Plastic Panels Acrylic Cladding Panels Styrofoam Building Panels Fabricated Wall Panels Woven Steel Mesh Panels Urethane Insulation Panels Modular Roof PanelsSandwich Panels India Supplier & Manufacturer from China

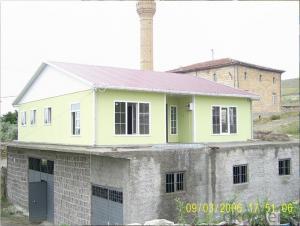

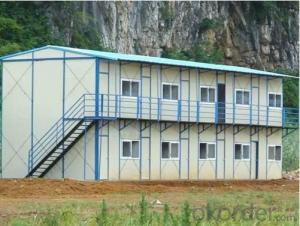

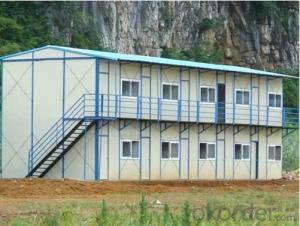

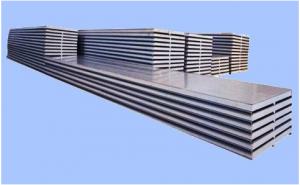

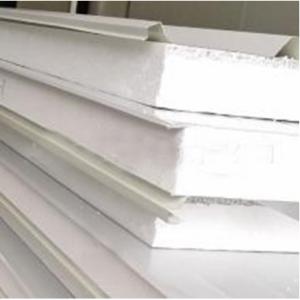

Sandwich Panels India offers a wide range of high-quality sandwich panels, which are engineered to provide excellent insulation and structural strength. These panels are made from two layers of metal sheets with a core of insulation material, such as polyurethane, polystyrene, or mineral wool, sandwiched between them. They are widely used in various industries, including construction, refrigeration, and transportation, for applications like roofing, wall cladding, and cold storage.The sandwich panels from Sandwich Panels India are designed to cater to diverse needs, such as thermal insulation, fire resistance, and soundproofing. They are commonly used in commercial and residential buildings, warehouses, and industrial facilities where energy efficiency and durability are paramount. These panels not only enhance the aesthetics of a structure but also contribute to its overall performance and longevity.

Okorder.com is a leading wholesale supplier of Sandwich Panels India, boasting a vast inventory that caters to the needs of various industries. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that the sandwich panels are manufactured to meet international standards and are available at competitive prices. This makes Okorder.com the go-to platform for businesses seeking reliable and cost-effective solutions for their sandwich panel requirements.

Hot Products