PU Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

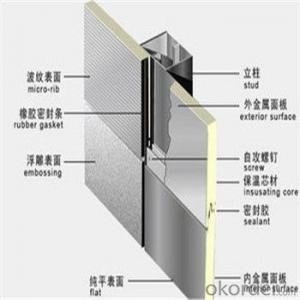

PU Sandwich Wall Panels

1. Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

2. Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

3. Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.Colored Corrugated Galvanized Steel EPS Sandwich Wall Panels

- Q: Logs, lumber (square wood, plate, specifications) from what kind of tree species, what characteristics, mainly used for what type of wood structure, the specification is how to grade?

- Wood refers to the already skin, roots, treetops of wood, and has been processed according to a certain size into the diameter and length of the material. Sawn timber, also known as corridor, plate; that is, according to a certain standard specifications or size of the re-processing molding. Conifers, broadleaf trees (such as various types of pine, cedar, cypress, camphor, ash, etc.) can be processed into logs and sawn timber. Conifers generally trunk straight and tall, smooth texture, uniform material, high strength, bulk density and expansion shrinkage smaller, better corrosion resistance. Is the main building materials, can be used as load-bearing components, furniture and so on. Broadwood tree trunk straight part of the general is relatively short, hard material, more difficult to process, heavier, swelling, warping deformation, easy to crack. Often used as a smaller component. Some tree species are beautiful, suitable for interior decoration, furniture and plywood. Wood structure of the specification of the wood to allow the stress level and elastic modulus are clear values, it is recommended to consult the specification.

- Q: Who has a natural marble sheet testing report template?

- Main Test Products Main Testing Products Granite Granite Marble Marble Quartz Stone Quartz Limestone Slate Roofing slate Complex veneer thin stone Artificial marble Artificial quartz stone Artificial quartz stone The following are the same as the " Main Testing Scope Visual dimensions and dimensions Petrographic analysis Gloss Gloss Water absorption Density Flexural strength Compressive strength Thermal shock resistance Abrasion resistance Slip resistance Coefficient of friction Coefficient of friction Frost resistance Fire to Reaction Shore hardness Mohs hardness Mohs hardness Acid resistance Radioactive radioactivity

- Q: How to identify the custom wardrobe or cabinet plate is large Asia E0 grade plate

- First look at whether it is a large Asian plate of formal authorized business, there is no authorized certificate. Then there should be a large board on the board logo.

- Q: Snow Ling plate quality how, I now want to decorate, intended to use snow plate

- Xue Ling plate that quality of the bar, green green, E0-class standards, trustworthy.

- Q: Millennium boat plate fake, how to identify.

- The main board are: blockboard, finger board, fire board, multi-layer board, gypsum board, fire retardant board, decorative panels, the main board of the United States, Such as all kinds of sheet products to play, in the entire East China market share of small, with the brand increasingly mature, and launched the floor wood doors, paint glue, decorative hardware and other products.

- Q: What kind of auxiliary materials / details of the woodworking board shop?

- F30 most commonly used, mosquito nails, J1010 those, there are F20,25, ST38,50, T50, self-tapping screws, slotted tapping screws, glass glue, foam glue, Handle, hardware (track, lock, hinge, door suction, bed hanging ..)) ... Ceiling: the main vice-long, screw, 8 sets! Gypsum board, silicon calcium board! The a lot,,

- Q: I only know plywood.MDF is a kind of plywood? Is MDF different from another board of plywood or just a piece of wood?

- 1, MDF is a medium density fiberboard (English name: Medium Density Fiberboard, abbreviated as MDF, referred to as MDF). 2, medium density fiberboard is a wood fiber or other plant fiber as raw material, broken, fiber separation, drying urea urea resin or other suitable adhesive, and then made by hot pressing a man-made sheet. Its density is generally in the range of 500-880 kg / cubic meter, the thickness is generally 5-30 mm. 3, medium density fiberboard is the mid-sixties developed products, in recent years the rapid development of production. Because it has excellent physical and mechanical properties, decorative properties and processing performance.

- Q: Want to do the whole wardrobe in the bedroom, because of the reasons for the budget so I would like to ask what kind of sheet to do the overall wardrobe more affordable, more argument, I recommend solid wood composite board, and some remember, we talk about , Ask a question, the bathroom cabinet with PVC or solid wood particles can be it?

- Now there are more on the market in the MDF, you can buy their own plate and then find workers on-site cabinet. The The Bathroom cabinet board to use a good moisture-proof plate, you can use melamine board

- Q: Which industries use stainless steel plates

- Kitchenware and decoration industry with the most.

- Q: What are the different characteristics of the plate?

- Lead plate can play the effect of radiation, the general plate does not have this ability. Understand the plate, you can go to China plate trading network to see, more types of plates.

Send your message to us

PU Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords