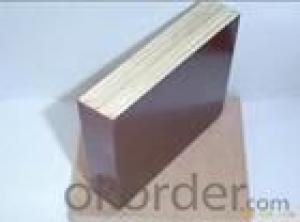

Phenolic Glue Commercial Plywood for 18mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

Detailed Product Description | ||

Place of origin | Shandong China | |

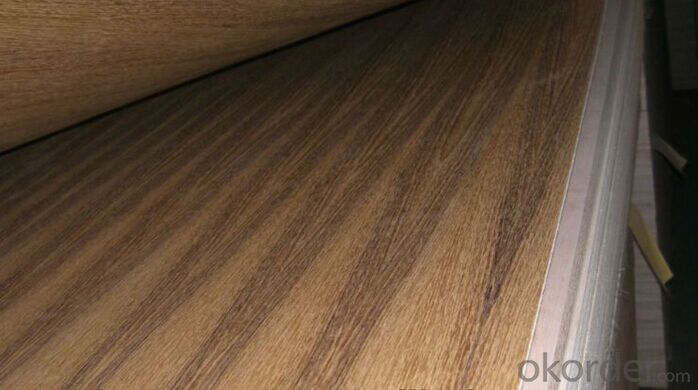

Face&back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested | |

Core | Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement. | |

Size | 1220*2440/1250*2500mm and as your requirement | |

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) |

1/4 inch(6-6.5mm) | ||

1/2 inch(12-12.7mm) | ||

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 2-6mm: +/-0.2mm | |

6-30mm: +/-0.3mm | ||

Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | |

Glue | MR,E1,E2,Melamine,WBP Phenolic | |

Moisture | 10%-15% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction, Furniture, decoration, packing. | |

Certificate | ISO9001: 2000; CE; CARB | |

Main market | Middle East, South Asia, South America, Africa | |

Shipment & payment | ||

MOQ | One container | |

Port | Qingdao | |

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | |

Delivery time | 2 weeks after your deposit | |

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | |

Advantage | ||

Capacity: 6000 CBM per month | ||

Sample available | ||

high quality and competitive price | ||

10 years’ experience in export | ||

Film Faced Plywood :

1.ISO9001:2008;CE;CARB

2.Face/Back: Black/brown/red/anti-slip film

3.Glue:E0,E1,E2,MR

4.Size:1220*2440/1250*2500mm

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Polyurethane color steel sandwich panels can not be used

- Can be used, but the splicing will be hot and cold bridge phenomenon, the loss of temperature. The best way is to use the local polyurethane sprayer spray foam, so no seams, the best insulation effect.

- Q: I've been on a diet for a week now and because of my new low calorie food i eat it's a struggle to even get to 1200 calories by the end of the day! I've been eating 3 sandwiches a day. They consist of whole wheat bread, one slice of ham, and one slice of cheese each. But i'm afraid eating six slices of whole wheat bread will make me gain weight even if I am eating them for the calories to get to at least 1200. Should I stop or is this alright?

- That all depends! It can be bad in the long run if you aren't getting balanced nutrients from the sandwiches. With just ham and cheese, there's no way you could be getting everything your body needs nutritionally! Try adding variety into your sandwiches using lettuce, tomatoes, different meats, different dressings, new veggies, etc. Of course, this doesn't mean to go overboard with any one ingredient - keep it healthy. And remember, don't always use fat free dressings; a lot of the time, when there are other veggies involved, they are best consumed with a healthy fat source for best absorption. Regarding the bread... whole wheat bread isn't always what it seems. Real whole wheat bread is made from real whole grains, and you must check the ingredient panel to ensure this is what you are eating; there has been a bit of trickery in the bread industry. The first ingredients should contain items such as whole wheat flour, 100% rolled oats, whole grain corn, etc. Any enriched flour, even if whole wheat, is not what you're after. Sandwiches can be great as long as they are balanced nutrition-wise, so if you really like 'em, I wouldn't say they are a problem. Just make sure your caloric intake is correct for your daily needs, and that you're getting some variety.

- Q: Rock wool color steel sandwich panels how to choose

- Shandong Yonggu Building Materials Technology Co., Ltd., Shandong Province is one of the largest manufacturers of insulation materials, the company was founded in 1999, is the production of new energy-saving insulation materials professional manufacturers, is one of the largest phenolic sheet production enterprises, and participated in the The preparation of national standards for the product. Yong company in good faith, innovation, management, technology in all aspects of comprehensive advantages, laid in the new insulation materials on the market position. Yong company introduced a number of patented phenolic products and continuous phenolic composite sheet production line, is committed to the development and improvement of low-temperature phenolic foam resin, hard phenolic foam board, phenolic refractory materials, phenolic wall insulation board, phenolic color steel sandwich Plate and other phenolic products. Now the scale of the production of the core products are phenolic wall insulation board, aluminum foil surface (color plate) phenolic duct plate, phenolic Caigang sandwich panels three series of new technology products. The company has introduced the automatic production line, the production of phenolic foam sheet density uniformity, smooth surface, smooth, to overcome the traditional hand-die large foam behind the process of poor strength, low efficiency, for your project to provide a strong Guarantee. The adoption of international advanced quality management, enterprises through a comprehensive ISO9001 quality system certification, and apply for access to five national patents. The company's superior products Caigang sandwich panels, color steel tile is the China Steel Structure Association designated supporting manufacturers, and won the "Shandong famous brand" "user trust units" and other honorary titles.

- Q: Would you like to check the flame retardant type of the metal surface rock wool sandwich panel of the activity board room?

- Surely, the requirements of the roof rock wool board will be higher, our company to do the roof rock wool board, there are inspection reports.

- Q: Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: 50mm thick roof color steel sandwich board price is generally how much money a m2?

- 50mm thick roof sandwich board is generally 65 yuan per square main to see how thick you want the steel plate

- Q: Color steel sandwich panels have what kind of ah?

- company's product: The company's main Caigang tiles, Caigang sandwich (rock wool, foam) insulation composite panels, car panels, frozen plate, C-steel purlins, municipal enclosures and other color steel products and its supporting various colors Steel accessories. The company's products are widely used in various industrial plants, clean room, cold storage, container-type mobile board room, fixed board room, canopy and a variety of building plus layer and other projects. Company purpose: The company promises to "handsome in appearance, reasonable structure, durable, low profit prices" with the majority of users wholeheartedly cooperation, join hands to create brilliant! Chongqing Caigang sandwich panel production

- Q: Color steel sandwich panel wall too heavy how to install?

- Fixed the area surrounded by the house. And then wipe with a sandwich panel inside, remember to play the following rivet yo sandwich board on a piece of a piece of sandwich (the sandwich plate itself slot) corner of the seat to pull the window with aluminum is empty out, so you can save a little (Of course you can dig your own wall in the installation of the wall can also be empty) out of the window to be filled with trough aluminum in the installation of plastic windows can be a door on their own in a full version of the cut with the top of the aluminum roof with angle iron and The following wall panels are connected and screwed.

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Or with sandwich panels, and now the market is a kind of better plate, called multi-layer solid wood or multi-layer plywood, the quality carry carry, and do the wardrobe is also very high Oh

Send your message to us

Phenolic Glue Commercial Plywood for 18mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords