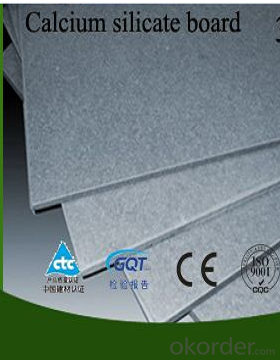

calcium silicate board ----Precast Concrete Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

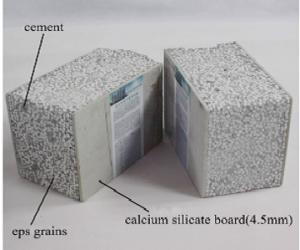

Composition: EPS+cement+calcium silicate board Package (20GP) Specification (mm) Quantity (pcs) Area (sqm) Weight (kg) 2270*610*60 306 424 19500 2270*610*75 252 349 18200 2270*610*90 207 287 17300 2270*610*100 189 262 17300 2270*610*120 153 212 15000 2270*610*150 126 175 13200 Usage Our wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings, residential houses, work shed and other constructions. It can be also used as non load bearing structure of washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement. Main Product Features: · Premium quality · Prompt delivery & seaworthy packing (20-40 days after receiving deposit) Reliable performance Easy and smooth operation High safety. · Professional Service · Competitive pricing Project

Q3: How do we guarantee the quality? A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Certificate

Q1: How soon can we receive the goods after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service?

A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q: Color steel sandwich panel thickness specifications are several

- Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs. The substrate of the color steel plate is a cold-rolled substrate, a hot-dip galvanizing substrate, and an electro-galvanized substrate. Coating types can be divided into polyester, silicon modified polyester, polyvinylidene fluoride and plastic sol. The surface condition of the color steel plate can be divided into coated board, embossed plate and printing plate. The color steel plate is widely used in the construction of household appliances and transportation industry. The construction industry is mainly used for steel industry, airport, warehouse and freezing industry. Commercial buildings of the roof walls and doors, etc., civil buildings using less color plate.

- Q: Color steel plate wall how many meters a general support, corrugated color plate non-sandwich panels

- Is there any angle between the top and bottom of the color plate? If not, the two panels at the junction should be set up a support point. If there is, 2-3 sets of color board can be set up to support, depending on the size of the project area average annual wind. We usually set up a 2 support.

- Q: Density board, sandwich panels, solid wood particle board What is the difference between the three, which is better!

- Density plate (English: High Density Board (wood)), also known as fiberboard, is the wood, tree technology and other objects in the water soaked after hot grinding, pavement, hot pressed, is based on wood fiber or other plant fiber Raw materials, urea-formaldehyde resin or other suitable adhesive made of artificial plate. Because of its soft and impact resistance, high strength, uniform pressure after the uniform, but also easy to reprocessing in foreign countries is a good material for the production of furniture, but the disadvantage is poor water resistance. Medium and high density board, is a small diameter wood grinding and grinding in the high temperature and pressure to suppress, is now common, and our standards on the height of the board than the international standard several times lower, so the density board in China The use of quality has yet to be improved. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs.

- Q: Hanging plate, color plate, sandwich panels, pressure plate the same?

- Sandwich panels and Caigang sandwich panels is one thing, are double-color steel plate folder folder insulation material, food production workshop with sandwich panels can

- Q: What is the polyurethane fireproof grade?

- Polyurethane sandwich panels are generally fire-resistant B2, can also reach the B1 level, belonging to the B-level self-extinguishing

- Q: I would like to build factories. Would like to ask the thickness of 10 cm under the foam sandwich board how much money a square.

- Only know the current price of foam board is 70 yuan a cubic (the lightest material), if coupled with the price of color steel, it is estimated that a flat price is more than ten dollars it Of course, the best choice of flame retardant, it should be more than 20 square.

- Q: Single door size is 450MM * 550MM, I would like to ask is the stone attached to the door whether it will be too heavy, is not conducive to the door hinge, hinge will withstand the living? The Thank you

- Marble factory is generally done 20mm slices, you are so big door that the stone will be a few pounds heavy, hinge, switch door use, are the problem. If you have to use marble, then you can order some thin marble, such as 8mm or thinner, but the price is estimated that you will not accept. And then you can buy ready-made glass imitation marble pattern decorative door, You can also use the wooden door, the appearance of paste Boeing film, is the kind of side is sticky, one side is the pattern of plastic sheet, These two materials in the building materials market can be found, and the basic can achieve the effect of marble.

- Q: How to use the 0.3x50 sandwich panel to do a hundred square meters of roof to install how much money? Guanzhong area.

- With a color coated steel plate, rust does not solve the problem.

- Q: We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- The purpose of the test is whether the material meets the design requirements The item is refractory grade

Send your message to us

calcium silicate board ----Precast Concrete Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords