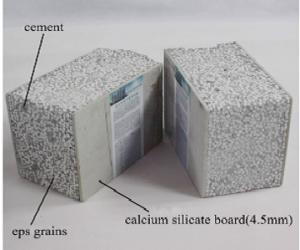

calcium silicate board --- Concrete Polystyrene Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composition: EPS+cement+calcium silicate board

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

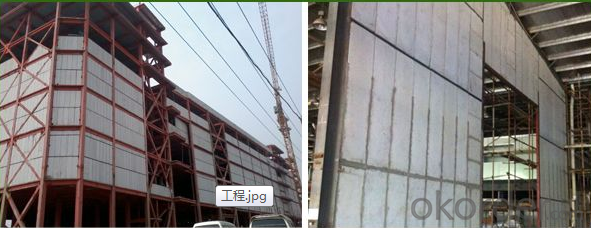

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase? A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service? A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- In fact, the effect of phenolic board are almost the same, manufacturers will be based on your needs to do, we also produce, not the fact that the phenolic foam is slightly better than other insulation board fire, but not so good, crack mortar a little sticky in the above

- Q: Caigang glass wool cotton sandwich panels are non - burning materials do

- Caigang glass wool cotton sandwich panels are non-burning materials, Caigang glass wool sandwich panels and rock wool sandwich panels belong to the same fire board.

- Q: what kinds of sandwich panel do we have?

- Typical laminated panels utilize foam, wood, or honeycomb cores sandwiched between high strength facing and substrate materials to produce lightweight panels with specific characteristic. All kinds of laminated panels with different specifications can be made to order.

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Magnesium cement curing to release a high heat, generally in the 1000 ~ 1350J / gMgO, and the heat release rate is very fast, the highest reaction system center temperature up to 150 degrees Celsius. Ordinary Portland cement hydration heat is only 300 ~ 400J / g, can be seen magnesite cement is the ordinary cement hydration heat 3 to 4 times. As can be seen from the above data, especially in the summer high temperature production, must strictly control the magnesite cement curing process. At present in Hebei Wen'an, Cangzhou area, in order to save production space, usually finished a board, and then according to this board for the operating platform in the above do 3 to 5, we all know, thermal conductivity of foam material is poor, and Ling Magnesium cement curing is a fast high heat process, so the production often encountered due to exotherm is too high and burned foam board situation, that is, "burn board" "hollowing" phenomenon.

- Q: With the production of sandwich panels can now control how many years?

- In general, sandwich panel covers the house! On the iron thickness of 0.4, under the thickness of 0.326, you can protect the new 10 years, no later than 2 years spray a paint, up to 25 years! Aluminized zinc is longer,

- Q: Sandwich board insulation roof sets what the amount of

- The so-called sandwich panels, in fact, should be color steel insulation board, right? If you can, you can set the color steel roof, but under normal circumstances the color steel roof is a single layer of color plate, you are the insulation board, you only need to take color steel roof and then the quota inside the single layer of steel plate for color steel Insulation sandwich board so that the provinces and cities are not the same as the amount of fixed content, the specific depends on your local quota requirements.

- Q: Color steel sandwich panels can be used for many years

- If it is GB double-sided 0.45MM Baosteel foam 16KG / M, then 25 years certainly no problem

- Q: What is the level of fire protection for the production of polyurethane sandwich panels?

- Class C plant.

- Q: Color steel sandwich panel can do the widest, can be more than rice

- The effective width of the color steel sandwich panel is based on the shape of the steel plate you choose. The surface of the sandwich panel has a flat plate and a few peaks, such as: 1) The surface is flat so that its effective width can reach 1.16 m The maximum width of the steel plate is 1.2 m due to the sandwich panel edge structure in order to increase the compressive strength to be folded 2 cm) 2) the surface is a wave shape of the steel plate that you should choose the peak size and size to calculate its maximum effective width.

Send your message to us

calcium silicate board --- Concrete Polystyrene Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords