Calcium Silicate Slag

Calcium Silicate Slag Related Searches

Calcium Silicate Fertilizer Silicate Salts Calcium Borate Calcium Aluminate Calcium Oleate Calcium Hypochlorite Caustic Soda Flakes Calcium Oxide And Silicon Dioxide Calcium Fluorite Calcium Chloride Crystals Calcium Fluoride Calcium Peroxide Solid Polycarbonate Carbon Graphite Block Ceramic PigmentCalcium Silicate Slag Supplier & Manufacturer from China

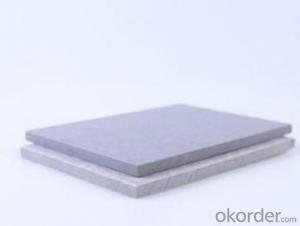

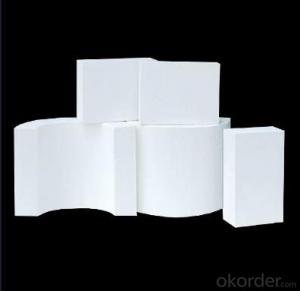

Calcium Silicate Slag, also known as slag wool or mineral wool, is a type of eco-friendly insulation material derived from the byproduct of the steel industry. It is composed of calcium, silicon, and oxygen, and is known for its excellent thermal, acoustic, and fire-resistant properties. This versatile product is widely used in various applications, such as building insulation, fireproofing, and noise reduction. It is particularly effective in construction projects where energy efficiency and safety are of utmost importance.Calcium Silicate Slag is increasingly being chosen over traditional insulation materials due to its superior performance and environmental benefits. It can be used in residential and commercial buildings, industrial facilities, and even in transportation vehicles to provide insulation and protection against extreme temperatures. The product is also non-toxic and resistant to moisture, making it a safe and reliable choice for a wide range of applications.

Okorder.com is a leading wholesale supplier of Calcium Silicate Slag, offering a vast inventory of this high-quality insulation material. With a commitment to providing the best products at competitive prices, Okorder.com ensures that customers have access to reliable and efficient solutions for their insulation needs.

Hot Products