Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

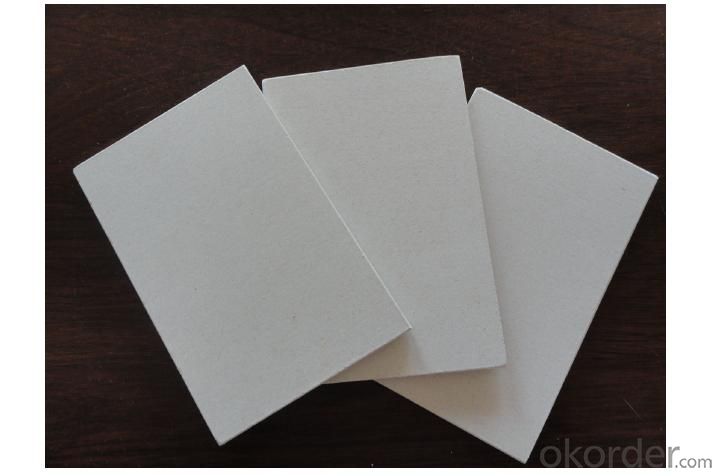

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

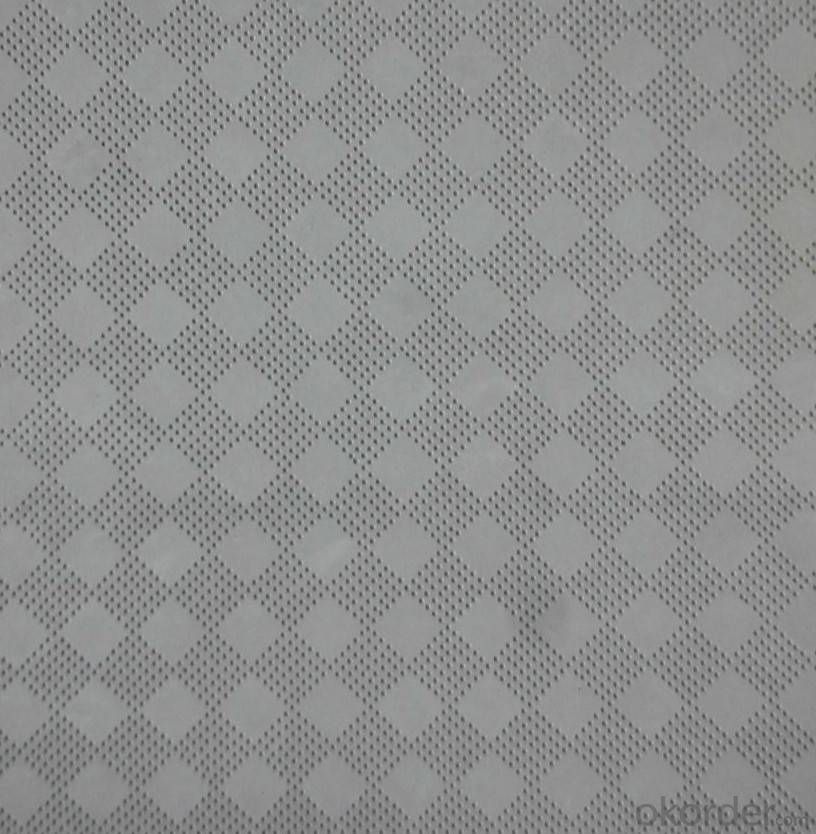

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476 standards

10) Two point five three hours of fire rating for 6mm wall system with W-CSP concrete

11) Radioactivity: GB6566-2000 standards

12) Characteristic: nonflammability A grade (GB-8624-1997)

13) Light weight

14) The wall is solid and firm inside, resistant to impact pressure

15) Painting, tiling and nailing is possible in the new system

16) Noise reduction can be up to 46dB

17) Good efficiency

18) Working environment can keep it dry and clean for better management .

19) Applications: can be used for partitions, interior walls, pipeline and conduit compartments, stair space, exterior walls, ceiling boards and pillar wrapping.

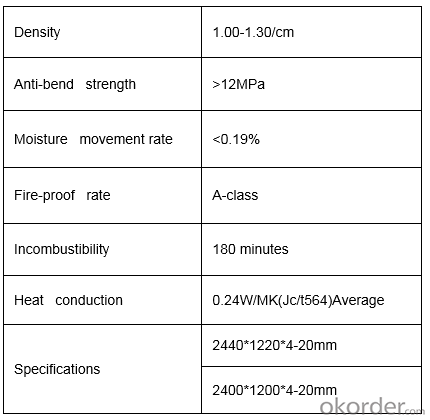

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: The difference between calcium silicate board and plywood

- Plywood do not know the amount, but with the use of adhesive resin is certainly not environmentally friendly, there is no fully resistant to aging organic resin

- Q: Calcium silicate board can be used in the roof

- Silicon calcium board has thermal insulation properties, can be used for roof insulation

- Q: Is the calcium silicate board gypsum board?

- But the gypsum board fire and water resistance is weak, it is being replaced by calcium silicate board. In price, the price of calcium silicate board is also slightly more expensive than gypsum board, but it is worth the money.

- Q: Silicon calcium board can be used for external walls

- The main reason is its advantages: light, moisture-proof performance is good, easy to change color, high hardness, good sound insulation performance. The calcium silicate board also has obvious shortcomings: the installation is not easy to replace, the installation of the use of iron keel, the price is more expensive and easy to break, slit. But now there are external walls with calcium silicate board, but from the cost point of view, the proposed external walls or do not use calcium silicate board

- Q: What is the silicate? What is the price of calcium silicate and the market is much worse?

- And we produce the cable is the same product, the main component is calcium silicate and wood pulp fiber, the main difference is to use more than 10,000 tons of press, the other surface to be painted. Our price is not so high

- Q: 6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- Artificial 40 square meters. Material 35 square meters. A total of 480 yuan ceiling, demolition, blocking and the like, a total of 200 yuan. Paint paint is 25 square meters (including labor) a total of 150 yuan. A total of 850-900 yuan can do a good job

- Q: Calcium silicate board water absorption on the performance of the plate have any effect

- Calcium silicate board If the strength of the plate after the impact of a certain degree of impact, low density of the plate is relatively higher than the medium density, it is recommended that wet areas such as the use of density in the basement of the plate, while the toilet ceiling, although relatively humid

- Q: What are the extruded boards and calcium silicate board adhesives?

- XPS extruded board and aluminum plate, aluminum-plastic plate, calcium silicate board, enamel brick, super-energy board, foam cement board, marble bonding, the specific model PU-50 two-component polyurethane adhesive, Water and cold resistance and a certain toughness. This adhesive in the domestic dozens of energy-saving wall insulation board manufacturers use for many years, without trial or unnecessary worry.

- Q: I would like to do three partitions in the room, with fiber cement board, gypsum board, fiber calcium silicate board which is better?

- If you want to recommend the use of fiber cement board or calcium silicate board, the two boards almost, if you say the sound insulation, then these three boards are not special noise board

- Q: Tempered glass backdrop and calcium silicate board background wall which is better?

- Everything is good, but let me choose. I think the tempered glass wall is better.

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords