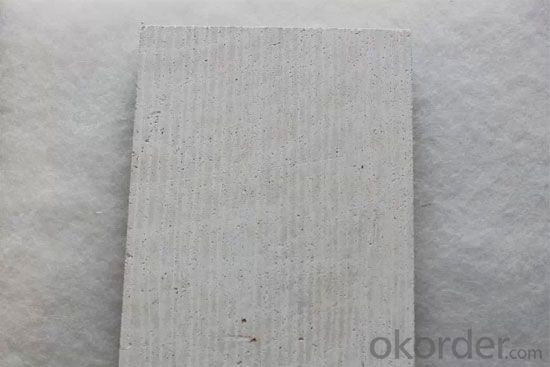

Low Price And High Quality Partition Wall Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

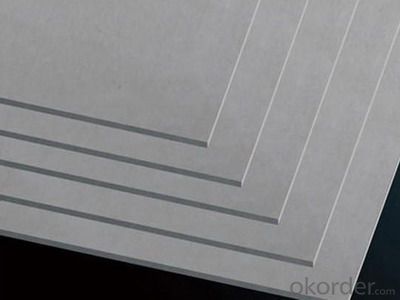

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

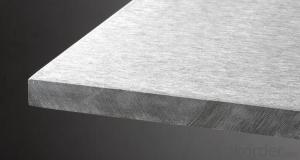

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

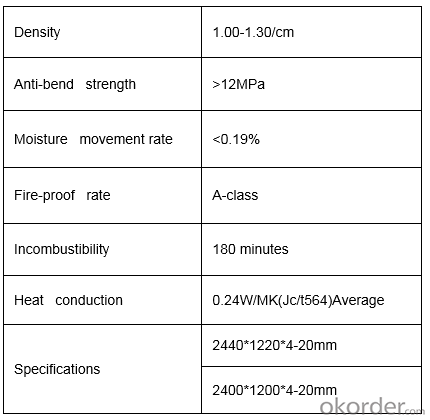

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Fiber reinforced calcium silicate board is to do with the cut off it?

- Calcium silicate board is non-polluting, environmentally friendly, new building materials, and aerated concrete and concrete hollow block, belong to the new wall materials, has replaced the traditional clay brick. Calcium silicate board in the high-rise building and frame light board building system, is an indispensable wall material for the construction of the wall of the factory complex; mechanized construction; put an end to the construction of wet operations;

- Q: Door head decoration, outside the aluminum-plastic plate which can be used calcium silicate board?

- Calcium silicate board is gypsum board, outside the sticky aluminum plastic plate if it is not very heavy, then there is no problem, which is certainly a reinforced keel structure, so do not worry about the problem

- Q: Glass magnesium board VS calcium silicate board who can be better

- Glass magnesium board is made of magnesium oxide, magnesium chloride, water ternary system is modified by the configuration, because of its A-class fire, water and moisture, while green, in line with the characteristics of sustainable development, by the state recommended.

- Q: Calcium silicate board sticky rock wool sandwich sandwich board what glue stick to live?

- Two-component polyurethane glue, recommended a line of shark cards, the effect is good

- Q: Calcium silicate board above the watermark is how to cause

- Calcium silicate board on the watermark is its wet embryo state, into the autoclave in the high temperature autoclaved curing process, the reaction of calcium silicate to form teromorelite crystals and water vapor in the surface condensation formation.

- Q: What is the difference between silicon calcium board and high crystal plate?

- Cost is also good. Recently we use the project with the high crystal plate ceiling, customers are also very satisfied.

- Q: What is the difference between silicon calcium and cement fiberboard?

- Fiber cement pressure plate and calcium silicate board are common architectural decoration materials on the market, its appearance and composition are many similar or even the same place, many people can not distinguish, and some businesses even calcium carbonate board posing as fiber cement pressure plate sales , Has reached the purpose of profit.

- Q: Calcium silicate board can do the shape of the ceiling? If the figure can not, figure in the shape of what is generally used to do?

- This can be done, because the technical problems can not do a lot of modeling, and now has been, if you are in Anhui, Anhui can send us to send new materials Co., Ltd. to see, we solve a lot of different modeling problems, perhaps There you need

- Q: How to identify whether calcium carbonate board contains asbestos?

- Asbestos calcium silicate board broken mouth will be very fine very fine wool (is plant fiber), after the fire is lit, is the smell of wood burning, no special smell; with asbestos calcium silicate board broken mouth will have Rough wool (asbestos), with the fire lit, there will be a very special smell, like the smell of plastic burning.

- Q: Calcium silicate board is not keel, you can directly nail on the wall?

- No, the same dragon skeleton. If you do not have a direct steel wall keel, directly with a wooden keel on it

Send your message to us

Low Price And High Quality Partition Wall Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords